Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:140 m²

Supply Capability:100000 m²/month

Specifications of Type ZA/ZB Manufactured Homes

ZA house:

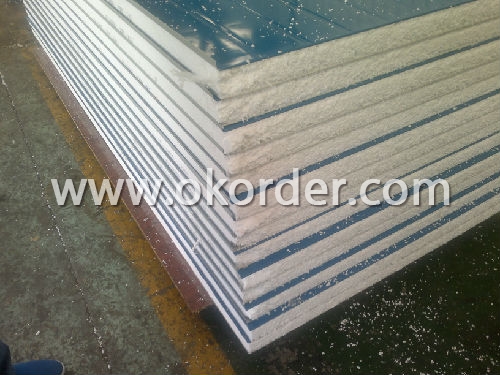

1. The house is made of galvanized structure and rustproof color steel sandwich panel as wall and roof.

2. Six skilled workers can finish 50m2 in 8 hours.

3. The house has waterproof structure and fireproof insulation material, such as EPS, rock wool and glass wool.

4. The house can resist heavy wind load of 0.5KN/M2 and 7-8 degree seismic intensity.

ZB house:

1. Air circulation between roof and ceiling creates a better insulation for room inside. Roof is color steel sheet and ceiling is color steel sandwich panel.

2. Six skilled workers can finish 50m2 in 8 hours.

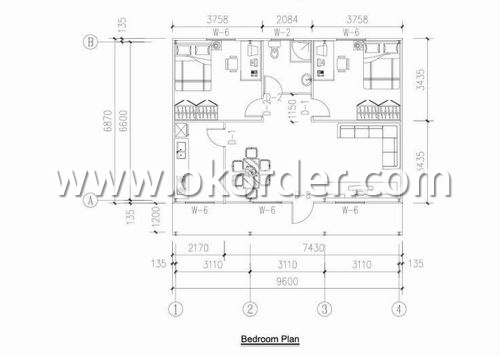

3. The size and layout can be designed as per customers’ requirements.

4. The house can resist heavy wind load of 0.35KN/M2 and 7 degree seismic intensity.

Items | ZA house | ZB house |

Life span(year) | 10-15 | 8-10 |

Advantage | Size and layout can be designed as per client's requirements, max span 12m. | Compared with ZA: 1.Less steel structure. 2. Double layer roof makes it cooler inside. 3.It's not so stronger than ZA cause the wall panels support roof system |

Wind load | 0.5KN/m2 | 0.35KN/m2 |

Structure | galvanized steel structure( C type steel ) | painted steel tube |

Wall & roof | EPS / rock wool / glass wool sandwich panels (50/75/100mm or customized) | EPS / rock wool / glass wool sandwich panels (75mm/100mm or customized) |

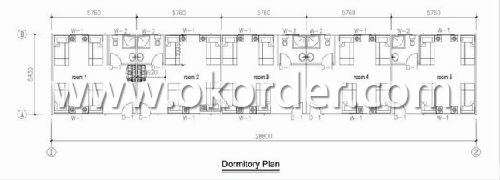

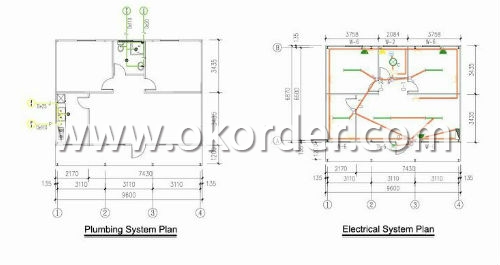

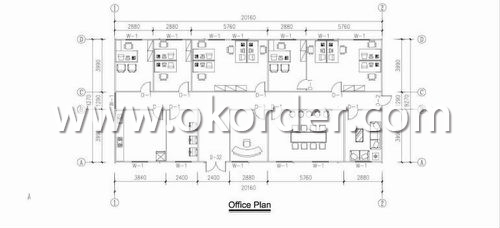

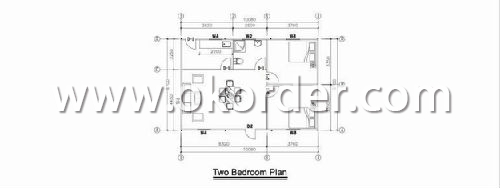

Production and Layout Plan of Type ZA/ZB Manufactured Homes

All of the items are made of steel structure and color steel sandwich panel.

Layout plan of the type ZA/ZB modular homes

Packaging & Delivery of Type ZA/ZB Manufactured Homes

According to the quantity, all the parts are packed separately in suitable ways and loaded by containers. One 40HQ container can load about 160m2 considering 75mm thickness panel for roof and wall.

Usage/Applications of Prefab House / Modular Homes

It is widely used in offices, sales offices, classrooms, shops, cafes, exhibition galleries, hospitals, dormitories, canteens, industrial plants, warehouses, parking lots, simple sheds, lean-room, movable guard post, modular villa, site temporary facilities etc.

Installation Steps of Prefab House / Modular Homes

1. Trenching

2. Foundation, brick foundation or concrete foundation

3. Install the steel frame

4. If the structure is multi-layer, to install the prefabricated floor

5. Color plate installation

6. First floor terrace installation

7. Install windows and doors

8. Interior decoration