Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:1 set/month

Profile

The rubber tyred gantry crane (for short RTG crane, also transtainer) is a mobile gantry crane used in intermodal operations to ground or stack containers. Inbound containers are stored for future pickup by drayage trucks, and outbound are stored for future loading onto vessels. RTGs typically straddle multiple lanes, with one lane reserved for container transfers.[citation needed] Advantages:its mobility gives a rubber tyred gantry crane wild appliance

Being mobile, RTGs are often powered by Diesel generator systems (gensets) of 100 to 600 kW. Due to the lack of an electrical grid to dump energy when containers are being lowered they often have large resistor packs to rapidly dissipate the energy of a lowering or decelerating container.

Aside from the intermodal industry, RTGs also are extensively used in industry. Applications include erecting large unbalanced structures, assembling large manufacturing components, and positioning pipelines.

The rubber-tyred gantry crane is designed to handle、load and unload international standard containers. It has advanced function, high productivity, great maneuverability and low sensitivity on the uneven ground. The power of crane is supported by the diesel generating set. The oil pipeline and hydraulic system can be operated at low temperature with heating devices. The crane is also equipped with perfect safety instructions and overload protections which aims to ensure the safety of operators and equipment. The electric system adopts to PLC variable frequency control which is favorable to control all of the mechanism. Associated parts are selected and purchased from well-known fitting manufacturers at home and abroad. Thus, it guarantees the quality of crane as a whole. Rubber-tyred gantry cranes are designed、manufactured and tested in line with international advanced foreign standards such as DIN、FEM、IEC and AWS and the latest version of the state standards.

Technical Parameters

Specification | 35t | 41t | 45t | |

Rated lifting capacity(t) | 35 | 41 | 45 | |

Gauge | 7 | 7 | 7 | |

Span (m) | 23.47/26 | 23.47/26 | 23.47/26 | |

Lifting height(m) | 15.5/18.5 | 15.5/18.5 | 15.5/18.5 | |

Numbers of stacking storey | 4/5 | 4/5 | 4/5 | |

Specification of container | 20 ‘ 40 ‘ 45’ | 20 ‘ 40 ‘ 45’ | 20 ‘ 40 ‘ 45’ | |

Lifting speed (m/min) | Lifting (full, empty load) | 25/50 | 25/50 | 25/50 |

Crane traveling(full, empty load) | 30/130 | 30/130 | 30/130 | |

Trolley traveling | 70 | 70 | 70 | |

Number of wheels | 8 | 8/16 | 16 | |

Max.wheel load | 320 | 345/172 | 174 | |

Power supply | Three phase AC,380V 50Hz | |||

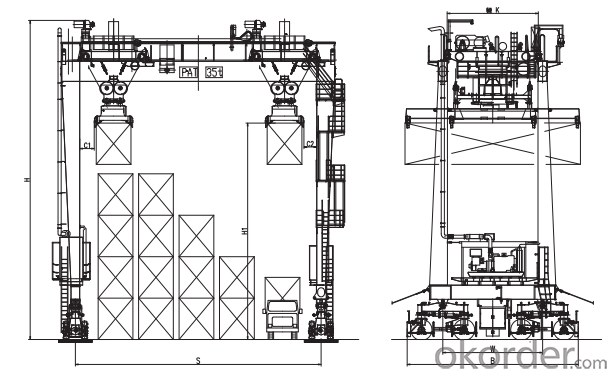

Sketch

Function

The Rubber Tyred Gantry Crane (RTG) specified herein will be used and operated in the New Mooring Container Terminal within the Chittagong Port protected area for handling 20', 40', 45’, 48' etc. loaded and empty ISO containers.

The crane is diesel electric powered and rubber tyred mounted type with the ability to operate in stacks of one over six high containers with six container rows. One extra space under the gantry is to be provided for loading and unloading of containers from chassis. Ample clearance shall be provided for transfer of container above the six 6 tiers.

The Rubber Tyred Gantry Crane (RTG) is operated in manually controlled mode. Hence, the crane shall have the option for manually controlled operation. The manually controlled operation will be aided by computer system.

Structure

The structures is fully welded steel construction and shall have sufficient rigidity to prevent widening of the trolley rail span during operation, and The construction of the crane such that no water will be trapped in corners, recesses or pockets.Jacking pads is installed on the wheels rocker beams to facilitate the changing of tyres.

Lattice type structures and counter weight will not be considered.

Mechanism classification | Class of utilisation | State of loading | Group classification |

Hoist | T7 | L3 | M8 |

Traverse | T7 | L3 | M8 |

Travel | T7 | L2 | M7 |

Constitution

Main Hoist

The ropes reeving and sheaves of the main hoist system is designed such that wire ropes cannot come out from the sheaves grooves under any operating conditions. The design shall prevent excessive slackening of the main hoist ropes and shall reduce the hoisting speed when the ropes are slackened. A system for detecting rope slack condition through use of limit switches/ load cells is provided.

The hoist motor and brakes are housed in a weather-proof enclosure with forced ventilation. Modern AC motors with the protection IP55 or specially designed motors for out side use which do not usually require enclosures will also be acceptable.

Telescopic Spreader

The spreader is designed to handle ISO 20 ft, 40 ft, 45 ft, 48 ft etc. containers. The spreader is extendable to 20 ft and 40 ft. The design of the spreader shall ensure that all the components are positioned or protected from possible damages by protrusion of up to 25 cm, from overheight containers.

Spreader corner guides are fitted at four corners of the spreader to enable quick location of the twistlocks into containers. The corner guides shall be fastened by means of bolts and nuts on a slotted adaptor such that the bolts, when sheared off, can slide out of the slot without having to extract remaining sheared portion of the bolts. Details of corner guides shall be worked out with the purchaser.

-Speed Drive and Control System

Speed drives together with the PLCs, input/output modules and the control systems must be supplied by the same electrical drives maker.

All speed drives shall be high efficiency, high performance, flux-vector controlled AC inverter drives. The drives shall be designed and constructed to provide quiet operation and require little maintenance. Drives for hoist, trolley and gantry travel operations shall be installed in an electric control house on the girder/sill beam.

Sequence Control

All sequencing and inter-locking functions for drives, except emergency protection functions shall be performed by Programmable Logic Controllers (PLC). The PLCs shall be able to intercommunicate with each other through a standard network following the OSI (Open System Interconnection) communication architecture. The system of communication shall be properly structured, oranised and standardised. The PLC shall have multi-tasking and remote communication capabilities. Any of these PLCs in the network shall readily be able to interrogate other PLC connected to the same network. In the event of a failure of the PLC, the crane shall be capable of performing its functions at low speeds using direct control from the drives. Supplier shall submit details (product data sheets and schematic diagrams) showing the structure of the communication system reflecting the above required qualities in the technical tender.

Materials and workmanship requirement

All materials to be used in the manufacture of the Rubber Tyred Gantry Crane (RTG) will be new and the best of their respective kinds under well known international standards, codes and regulations.

Workmanship will be of the highest standard and quality in every respect; all parts of the work will be performed and completed according to modern practice by workmen skilled in their particular trades applying total quality control system. All parts of the work will be neatly finished.

The supplier will operate a quality assurance system approved by the purchaser, covering his own manufacturer, bought in components and sub-assemblies. Quality control may take the form of random inspections, non-destructive testing, performance testing and other accepted techniques as well as examination and general approval of sub suppliers.

Quality control system.

In general terms, the supplier will be able to demonstrate that he is taking adequate precautions on formal and regular basis to ensure that all parts of the crane will comply with specification and to avoid passing over defects of materials or workmanship that might subsequently lead to accident, premature failure or inadequate performance.

he Rubber Tyred Gantry Crane (RTG) will be brand new of current production series of the manufacturing plant and of well proven performance records. Readymade (1st hand and unused) RTGs can be offered from the respective manufacturing plant.