Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:1 set/month

Profile

Because of high-efficiency working performance, high-usage of site, high-degree of automation, low failure rate, low energy consumption, low operating costs, environmental protection and other advantages, the rail-mounted gantry container crane(for short RTG) is attracting more and more favors. At present, more and more new-built large-scale professional harbors give up traditional rubber tyred gantry container crane(for short RTG) adopting the rail-mounted gantry container crane to handle the materials at the storage yard.

Mostly, the main girder of the rail-mounted gantry container crane adopts bias-rail girder. Generally, it is not needed to set additional walking board. In terms of the crane without saddle rack, it also can adopts regular girder or local bias-rail girder. When the rail-mounted gantry container crane is not set with cantilever, the both ends of the main girder will not equip cross girder. Closed to the upper location of the supporting column adds a link girder, which aims to control the horizontal deformation of the main girder and is similar with the pattern of the portal structure. In terms of the rail-mounted gantry container crane with cantilever, on the both ends of the upper cross girder add the horizontal stiffness and torsional rigidity of bias-rail girder. But in order to avoid the clashing between the trolley of the crane and the upper cross girder, the length of the main girder should be extended properly. The calculation shows that the adding length of the upper girder also can increase the torsional rigidity. When the span is quite big, in the middle of the main girder can add two control main girders, horizontal deformation and torsional deformation saddle rack(on the upper of the saddle rack, it also can equip with electric hoist which aims to maintain the crane.). Certainly, when the span of the rail-mounted gantry container crane is too big, it will decrease the working performance. Also, it will increase the possibility of the off tracking of the rail-mounted gantry container crane.

Ladder landing

To a certain degree, the quality of the ladder landing will influence the usage conveniences of the rail-mounted gantry container crane. No matter where it is needed to repaired, it will set ladder landing, such as the following places, connecting flange of main structure, access hole flange of main structure, mounted bracket with steel wire-rope, flood light, outside machine of split air conditioner, wind velocity indicator and other places.

Inclined ladder

Under the permitting of the space conditions, the rail-mounted gantry container crane should adopt inclined ladder preferentially or not using the straight ladder as far as possible. At early, the inclined ladder of the rail-mounted gantry container crane adopts welding way to fasten the up and down platform. It will easily cause fatigue cracking at the weld joint when it has been used for a long time. After that, it adopts hinge joint at the upper of the inclined ladder and the bottom is lapped under the platform. But in this way, the galvanized layer under the galvanized granting plate is easy to be ground away.

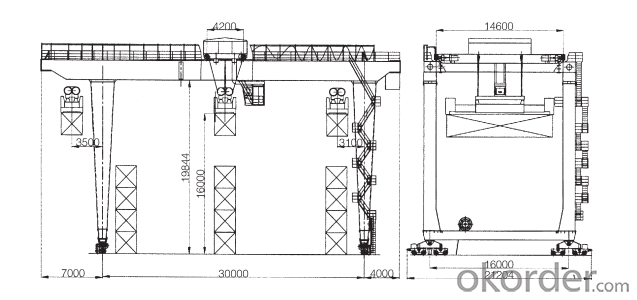

Sketch

Technical Parameters

Rated Lifting Capacity | t | 35 | 41 | 45 | |

Wheel Gauge | m | 12/16 | 12/16 | 12/16 | |

Span | m | 30/35/40 | 30/35/40 | 30/35/40 | |

Lifting Height | m | 18.5 | 18.5 | 18.5 | |

Number of Stacking Storey | 5 | 5 | 5 | ||

Specification of Box | 20’/40’/45’ | 20’/40’/45’ | 20’/40’/45’ | ||

Speed | Hoisting | m/min | 25/50 | 25/50 | 25/50 |

Cart Travelling | 60 | 60 | 60 | ||

Trolley Travelling | 70 | 70 | 70 | ||

Number of Wheels | pcs | 16/24 | 16/24 | 16/24 | |

Max. Wheel Pressure | 240 | 240 | 240 | ||

Power Supply | 3-Phases AC, 380V 50 Hz | ||||

Rail Mounted Gantry is designed to handle the international standard boxes in the container stacking yards and railway container transfer stations. It has reliable performance and high production efficiency and is convenient for maintenance. The lower trolley can be rotated and pass through between legs, thus making the range of operation wider and mode of operation more flexible. The crane is also provided with perfect safety indicators and overload protection devices in order to ensure the safety of operators and equipment. The electric control system uses PLC variable frequency speed control which is favorable for control of all the mechanisms. Associated facilities are selected and purchased from well know fitting manufacture at home and abroad so as to guarantee the quality of crane as a whole. RMG is designed and manufactured according to the advances foreign standards such as DIN, FEM, IEC and AWS and the latest version of the state standards.

Cleaning of cab

When the Rail Mounted Gantry works, the driver should be often looks down the container spreader through the glass at the bottom of the driver's cab to see whether the four corner of the spreader is aligned with the container, and whether the spin lock locks the container reliably. Therefore, the bottom glass of the cab must be kept clean. Because of floating dust or bulk dust attached to the outside of the glass, often makes the driver can not see clearly; The outer side of the bottom glass (i.e. the lower surface) can not be cleaned at all. Therefore, a cab cleaning platform is hung in the middle part of the upper crossbeam of the driver's cab. The cleaning platform adopts L frame support, the lower platform can clean the bottom glass of the driver's cab, and the middle platform is kept the same height as the driver's cab platform, so that the platform can be conveniently passed. The lower and middle platforms are connected by a straight ladder, and the platform can be up to the upper cross beam platform. There are also other kind of RMG installed mirror in front of the driver's cab, in order to facilitate the driver from different angles to observe whether the spreader lock is in place.

Bearing seat type of running mechanism

There are many forms of bearing block for wheel set of cart and trolley running mechanism of crane, and the bearings which are reliable, easy to repair and adjust should be selected. The bearing seat of the wheel group of the car running mechanism is divided into an angular bearing seat, a 45 degree split bearing block and a adjustable bearing seat with round flange. The three kinds of bearing housings can be easily disassembled and assembled, but it is recommended to adopt the adjustable bearing block with round flange, which can can adjust the wheel angle to control wheel deviation and rail biting. The wheel group of the cart running mechanism has two forms which are the shaft type and the non rotating shaft type, most of the port machinery uses non rotating wheel group in early stage, the wheel shaft does not rotate with the wheel, it usually operate through the card shaft or shaft end cover fixed on the frame. At present, the newly developed port almost adopts the rotating type wheel group, it together with the wheel shaft to rotate synchronously in the rotating shaft supporting frame by a bearing seat. Rotation shaft is divided into an angular bearing seat, a 45 degree split bearing block and a adjustable bearing seat with round flange, the latter two kinds of bearing seat should be selected preferentially by RMG.