Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:10000 roll

Supply Capability:6000000 roll/month

This is a new environmentally friendly aluminum foil bubble heat insulation material, which is soft, light and easy to install. It is made from aluminum foil and polyethylene through special machinery.

Can be installed on roof, wall or floor, resist over 80% external heat from buildings, protect wall, resist thermal shock and sudden cold, etc.

1.No odor and toxicity, environmentally- friendly;

2.Moisture barrier, sun-proof, waterproof, good sealing property, heat preservation, energy saving…

3.Heat reflection, heat insulation, sound insulation, anti-radiation, anti-vibration, and shielding;

4.Light, soft, dust free, fire retardant, easy to install;

5.Summer: moisture barrier, sun-proof, heat insulation, saving energy consumed by cool air conditioning ;

6.Winter: heat preservation, central heating saving, and remarkable energy-saving effect.

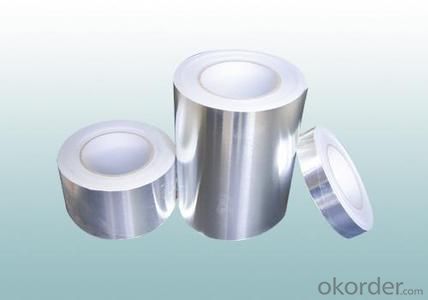

Packing of Aluminum Foil Tape

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Pictures of Aluminum Foil Tape

Specification of Aluminum Foil Tape

Material structure: AL/woven /AL | ||

weight: 0.13 KG/M2 | ||

Roll size: 1.2M W*40M L (can be customized) | ||

PROPERTIES | Test Data | Unit |

Thickness | 3.5 | MM |

Weight | 256 | G/M2 |

Emissivity | 0.115 | COEF. |

Thermal conductivity | 0.034 | W/M0 |

Apparent Density | 85 | KG/M3 |

Reflectivity | 95-96 | % |

Water Vapour Transmission | 0.013 | G/M2 KPA |

Corrosion | Doesn't generate | |

Tensile strength (MD) | 16.98 | Mpa |

Tensile strength (TD) | 16.5 | Mpa |

Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.