Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

General

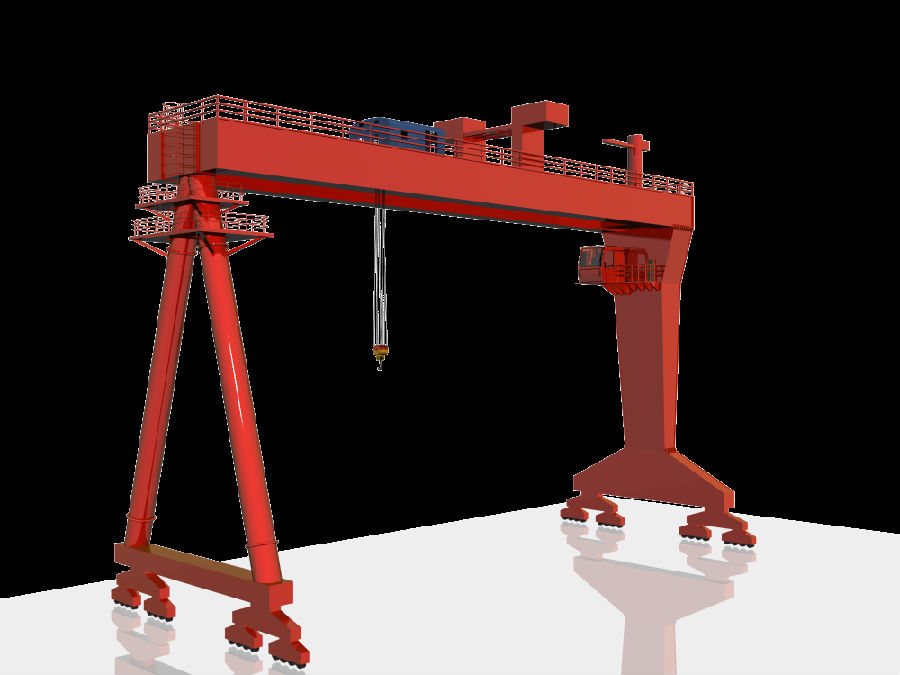

Electrical Single-girder Gantry Crane is used together with CD MD Model electrical hoists.

It is a track travelling small and medium-sized crane.

Its proper lifting weight is 5 to 10 tons, proper span is 12 to 30 meters, its proper working temperature is

-25°C to 40°C

It has two controlling methods, namely ground controlling and room controlling.

Feature

1)Power source is three-phase alternating current,rated frequency is 50Hz, rated Voltage is 380V.

2)The altitude height of site is ought to be less than 2000M.

3)Flammable,explosive and corrosive gas are forbidden in the work environment.

4)The crane is forbidden to lift fuse and blend deleterious article and flammable explosive article.

Technical characteristics

This crane has hard surface gear reducer and steel rope and three-in-one transmission mechanism.

Protective functions are as the following:

1)Acoustic-optic alarm, hook automatic stop protector, circuit protector and over current and

phase lose protection and intelligent limit.

2)The electric devices adjust speed without contactor spark module and fulfill frequency convert function to

reach mini-speed and double speeds, which make travelling and lifting very steady.

3)The operating board (handle) adopts 12V safe voltage.

4)The electronic controlling can be used more than 2 million times when the voltage is +5~-10% of 380V.

Choosing principle of single gantry crane

According to the working system and using field. Which system you will choose, field should go first.

Calculating the times per hour of starting and pulling-on recycle,you should make the practical time per day

and continuous time

When select or appraise, you should be sure such items as field, all the limiting size, ambient temperature,

speed, time(h), intermission or continuous, the time of starting and pulling-on per hour, etc.

The above mentioned is just for reference. Reasonable selection, design and match can increase the working efficiency greatly.

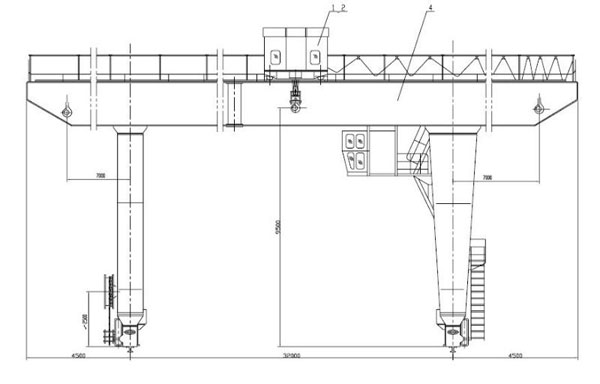

Layout

table parameter

Lifting capacity | t | 5 | 10 | |||||||||

Span | m | 18 | 22 | 26 | 30 | 35 | 18 | 22 | 26 | 30 | 35 | |

Lifting height | m | 10 | 11 | 10/10.5 | 11/11.5 | |||||||

Work system |

| A5 | ||||||||||

Speed | Main lifting | m/min | 9.0 | |||||||||

Aux lifting |

| 9.0 | ||||||||||

Trolley traveling | 35 | |||||||||||

Crane traveling | 30 | |||||||||||

Total power | KW | 22.8 | 25.8 | 36.8 | 39.8 | |||||||

Max wheel load | KN | 160 | 166 | 185 | 231 | 233 | 225 | 256 | 239 | 286 | 298 | |

Recommended rail | Kg/m | 43 kg/m | ||||||||||

Power supply | 380V, 50Hz, 3P( we can design cranes according to client’s local power source) | |||||||||||

Workshop picture