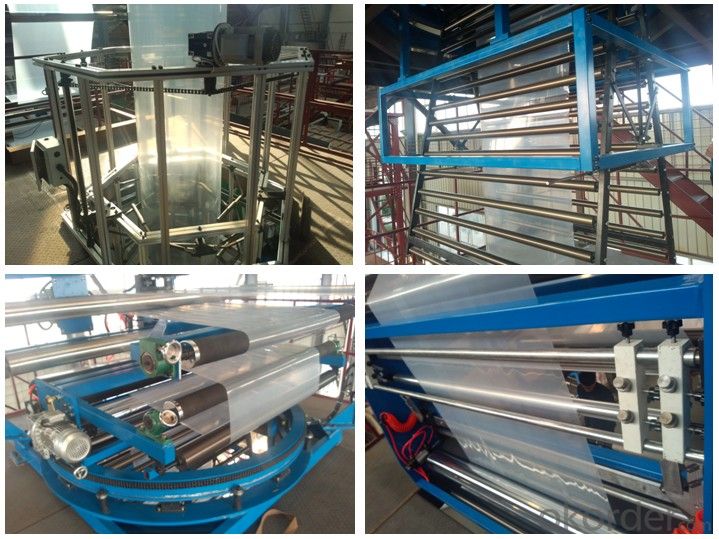

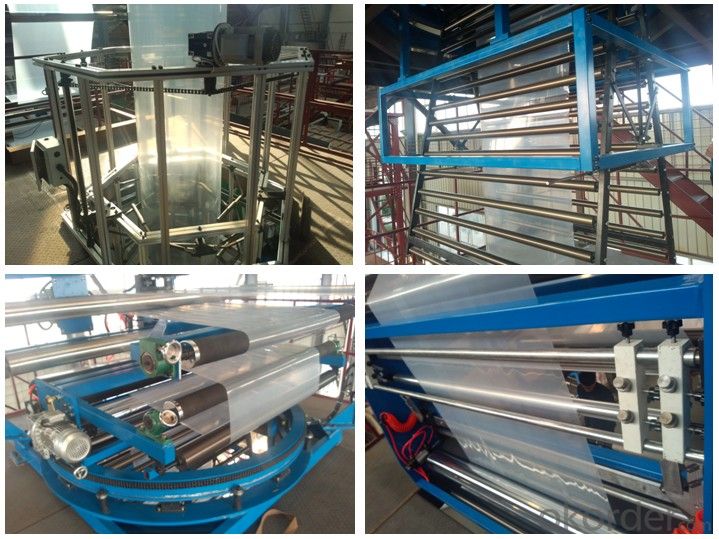

Seven layer Film Blowing Machine for Food Package

Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

Product Description:

1, Main Technical Parameters

1.1 Product Specification: Width 1400mm Thickness 0.025~0.120mm

1.2 Suitable Materials: LDPE, LLDPE, mPE, EVA or mixed materials.

1.3 Product Quality: Film thickness and limit deviation: 0.025~0.060mm≤±8%

0.061~0.120mm≤±7%

1.4 Total Installed Power: About 170KW

1.5 Maximum Output: About 170Kg/h

1.6 Dimensions: (L×W×H): 9.75×6.6×9.0m

1.7 Total Weight: About 18tons

2, Configuration2.1 Extrusion system (Extruder)

Equipped with 5sets of SJ55x32 and 2set of SJ65x32 single screw extruder which have

advantages of good production efficiency, low energy

consumption and good plasticization. 2.2 Die head system

Die head is introduced the advanced German technology, through CAD optimal design,

processed with German TC2.8K four-axis simultaneous machining center. The die will have

features of high precision, good brightness without deformation.

2.3 IBC system

IBC (ultrasonic closed-loop servo-control) system is consists of gas exchange device,

internal cooling air ring, in/out air blower, signal detection and control circuits, etc. The

system can rapidly cooling the bubble, exhaust inner heat, water molecules and emissions

of bubble, supply new cooling air, cool the inner temperature of the bubble, increase the

production output and improve the mechanical properties of films. 2.4 Traction system

2.4 Traction system

Horizontal ±360°reciprocating rotary can guarantee the linear velocity of film product

always stay consistent. The driving mechanism, haul off device and V-shaped plate hauls

the bubble for 360°uniform rotary at the speed of 0.1-0.3r/min to make the film deviation

which caused by die head, air ring and tower frame being 100% randomly distributed, thus,

to guarantee the whole quality of formed film product.

2.5 Automatic winding system

With the features of advanced technology, safe operation, easy maintenance, the winding

system can automatically change, cut and unload the rolls, which highly reduces the labor

costs and enhances the effectiveness.

2.6 Computer control system

Control method: Mitsubishi PLC control technology

2.6.1 One set of main control cabinet, adopts one set of three-in-one cabinet. (AC

contactor, low voltage fault positioner from Schneider, SSR from Taiwan Yangming)

2.6.2 Display part: adopts 10.4" touch screen for the operation (traction, winding, metering,

IBC, synchronous tension, cooling control of inlet/outlet blower).

2.6.3 Yaskawa frequency inverter for extruder motors, and domestic frequency inverters for

the rest.

- Similar Products

- New Products