Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:15 m.t.

Supply Capability:30000 m.t./month

General Information

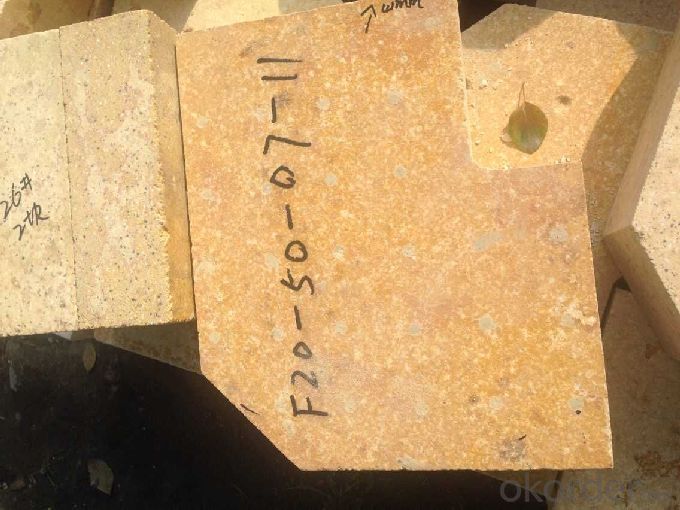

Silica brick is universal materials for the lining of molten pretreatment equipments of molten iron tank, torpedo car, etc. The products are shaped by machine power by using dense bauxite clinker and brown fused alumina as base materials and adding high quality SiC fines and high purity flake graphite. It has the advantages of excellent slag resistance, thermal shock resistance, good resistance to mechanical erosion, abrasion resistance, etc.

Features

1.High purity

2.Long service life

3.Accurate size tolerance

4.Pure color

5. Luster appearance

6..Good thermal conductivity

7.Good creep resistance

Application of the refractory silica bricks

Silica brick is mainly used for Coke oven, glass kiln, hot-blast stove, tunnel kiln,Acidic furnace non-ferrous metal smelting and some other thermotechnical equipment in good furnace building materials.

Physical & chemical indexes of the refractory silica bricks

Silica brick for Hot-blast stove | ||

Item | Dome wall brick | Checker |

SiO2 % ≥ | 95 | 95 |

Cold crushing strength Mpa ≥ | 35 | 30 |

Apparent porosity % ≤ | 22 | 23 |

Creep rate(0.2MPa,1550°C,50h)% ≤ | 0.8 | 0.8 |

True density g/cm3 ≤ | 2.35 | 2.35 |

Thermal expansion(1000 °C)% ≤ | 1.26 | 1.26 |