Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

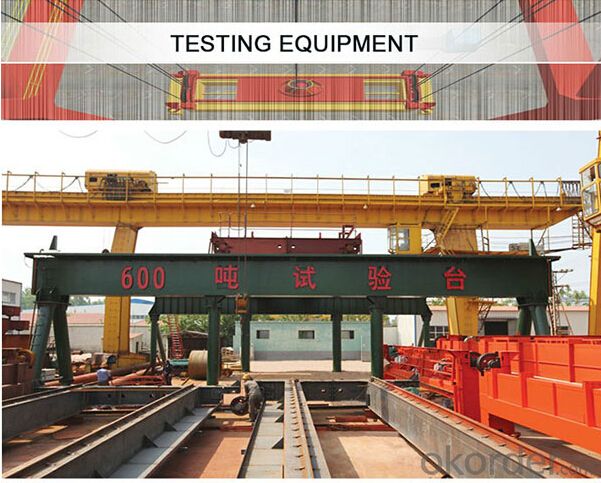

Rail Mounted Gantry Crane

Quick details

Feature: Gantry Crane

Rated Loading Capacity: 10-100T

Max. Lifting Height:No limited

Brand Name: KUANGYUAN

Warranty: One year

GB/T 19001-2000 idt ISO 9001:2000:Passed

Weight overload protection function:Included

Buffer:Polyurethane materials

______________________________________________

Condition:New

Rated Lifting Moment:Different

Span:

18~35m (it can de redesigned) as client's requirements)

Model Number:U Model

After-sales Service Provided:

Engineers available to service machinery overseas

GB/T 28001-2001,OHSAS18001:1999:Passed

Crane traveling limited switch:Included

Motor:High quality,famous brand

__________________________________________________

Application:Widely

Max. Lifting Load:100T

Place of Origin: Henan China (Mainland)

Certification: CE/SGS/GOST/ISO

GB/T 24001-2004 idt ISO14001:2004:Passed

Current overload protection system:Included

Emergency stop system:Included

Electric main parts:Siemens brand

__________________________________________________

Packaging & Delivery

Packaging Detail:Electricals and other parts are packed by high quality

plywood crates. Main beam packaged by plastic film and woven plastic cloth.

Delivery Detail: Within 45days after receiving your deposit

__________________________________________________

Specifications

Container Gantry Crane Loading/unloading containers with high efficiency, CE/ISO/SGS Certificate Loading capacity:10~100t

Rail Mounted Container Crane - (RMG) Gantry Cranes

Capacity: 20t/10t ,32t/10t ,36t/16t, 40t,50t,65t,

Usage: container terminals, open storage yards and along the railway lines to load or unload container

Technical Introduction:

The electrical equipment is accommodated in robust steel plate control cubicles.

All movement can be switched off by actuating the emergency-off switch at the control station via a main contactor.

The entire equipment is easy to install and dismantle due to the use of threaded bolts and top-hat rails. Cable inlet from the cable gland.

Power supply cable and control cable along the girder

A protective earth conductor is fitted as standard, a crane switch is provided.

Travel end switches, long and cross travel limited y means of preliminary and final limited switches and overload protection:

Design Structure

it runs on a runway at the floor level. The bridge is supported by a pair of rigid steel legs which are carried by a pair of end trucks along

the floor level runway.

Design Structure

it runs on a runway at the floor level. The bridge is supported by a pair of rigid steel legs which are carried by a pair of end trucks along the floor

level runway.

Mechanical feature

Double welding box girder, DIN/FEM standard deflection

Steel tube legs

Material Fe37 or Fe52

Whole length CNC cutting for complete web plate, high deflection accuracy

High quality autometic welding and NDT inspection

Shot-blasting Sa2.5 for complete girder after welding, stress release

Epoxy zinc rich high quality paiting, 2x2 with 140um

10.9 class High tension bolts mouting between girder and legs, life time safety connection

Vertical gear motor driving,more safety and smaller space