Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:100 kg

Supply Capability:10000 kg/month

| Place of Origin: | China | Brand Name: | CMAX | Model Number: | micropores insulation board |

| Material: | PTFE | Thickness: | 3mm-100mm, 3mm-100mm | Size: | Length & Width: 500mm*500mm,600mm*600mm,1000mm*1000mm,1200mm*1200mm |

| Certificate: | ISO9001:2000,ISO9001:2008 | Coating: | alumina foil/ glass fiber cloth | Length & Width: | 500mm*500mm,600mm*600mm,1000mm*1000mm,1200mm*1200mm |

| Grade: | A grade (100% virgin), B grade (50% virgin), C grade ( 30% virgin) | Polytetrafluoroethylene: | PTFE,also named TEFLON. | Characteristics: | includes molded sheet and skived sheet |

| Applications: | used within -180℃~+260℃ | Delivery: | 7 days after the receipt of the deposit | Packaging: | Pallet or according to customer requirement |

| Packaging Details: | 1.Paper-carton with polybag inside. 2.Paper-carton with polybag inside snd pallet. 3.Paper-carton with polybag inside and shrinkable film and strapped. |

| Delivery Detail: | 25 Days |

1.Calcium silicate fire-proof board / pipe/ brick / materials for aluminium/Power/Cement/Nonferrous/steel industry.

Microporous Insulation Boards are specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous insulation boards when moisture may occur due to castables, mortar etc.

Micropore Insulation Boards can be as much as four times more effective than conventional insulation materials. In practical terms this means that a Micropore Insulation Boards system can be only one quarter of the thickness for equivalent thermal control. This becomes crucially important wherever space is limited.

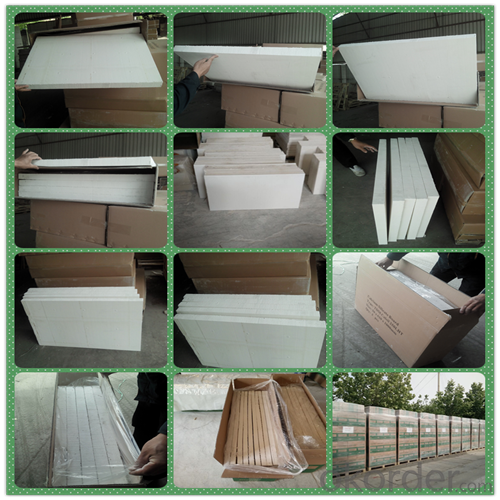

2.Pictures of micropores insulation board

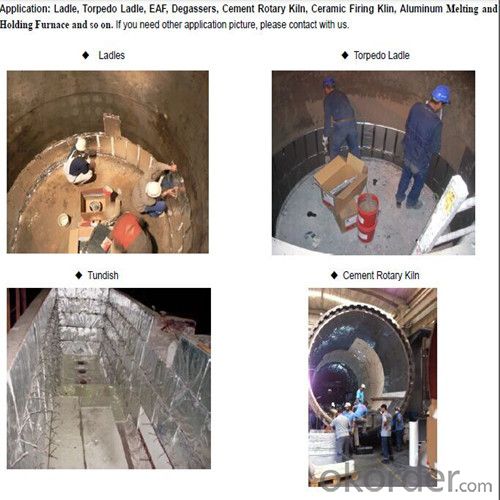

3. Applications of micropores insulation board

A. Cement industry: preheaters and cyclone separators, decomposition kiln,tertiary air duct and cooler .

B. Nonferrous metallurygical industry: aluminum power calciner and electrolysis groove.

C. Petrochemical industry: Splitting furnace,catalytic cracking furnace,petroleumpipeline,underground heat-flooding.

D.Metallurgical industry(steel plant): hot-rolling heat furnace,cool-rolling mill set,RH vacuum degassing furnace , smelters,hot deformation and heat treatment plants.

E. Power plant:preheat stove ,pipe.

F.Glass industry:melting furnace and recuperator,annealing furnace and cooling channels.

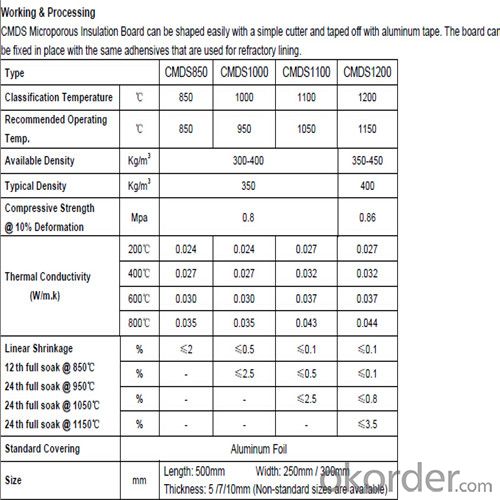

4. Technical of micropores insulation board

5.More Products To Choose

Our Services

1) High performance cost ratio with steady quality

2) OEM service and Prompt Delivery

3) The fast speed of reply your email and can make quotation sheet just for you.

4) Can provide free sample, only need you bear the sample fee.

5) Supply good after-sales service, we will follow-up the situation after using, if have problems,we will find out the

reason and deal with positively.

Other insulation products:

Welcome to visit our factory!!!