Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:10000 pc

Supply Capability:300000 pc/month

1.Brief Description

drywall partition metal stud profiles

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

Drywall partition metal stud profiles

Main data

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

3.For ceiling and wall part Drywall partition metal stud profiles

Main data

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

3.For ceiling and wall partition

4.Thichness:0.3mm-0.8mm

5.Length:3mm in common size ition

4.Thichness:0.3mm-0.8mm

5.Length:3mm in common size

6.Color:Silver white

7.Shap:U and C shap

8.Used with paper faced gypsum board or other products

Introduction

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC, FT and so on.

Advantages and Features:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

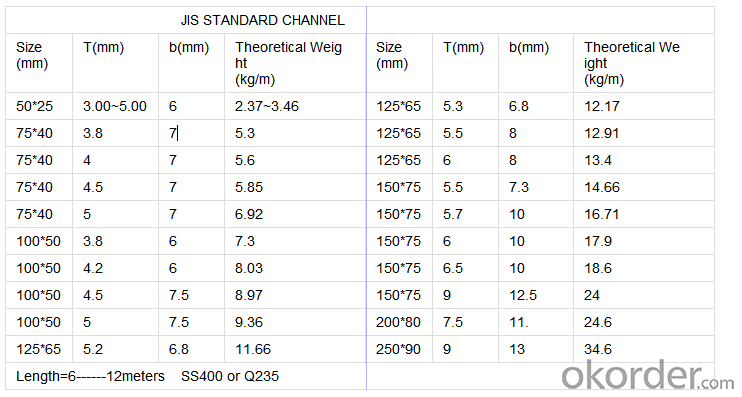

4.Detailed Specification

5.FAQ

Quality inspection procedure

1 At Pennon,10% employees are QC/QA workers.

2 Including Random-checks and sample-checks

3 Qualified rate is higher than 98%

4 We have five strict QC processes including incoming materials QC, IPQC (in process QC on patrol), LQC (line QC), FQC (final product QC) and OQC (output QC before shipping).

Payment