Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1000 m.t.

Supply Capability:10000 m.t./month

| Place of Origin: | Hebei China (Mainland) | Brand Name: | wzh | Model Number: | 950/1150mm for wall or ceiling or 950mm as roof |

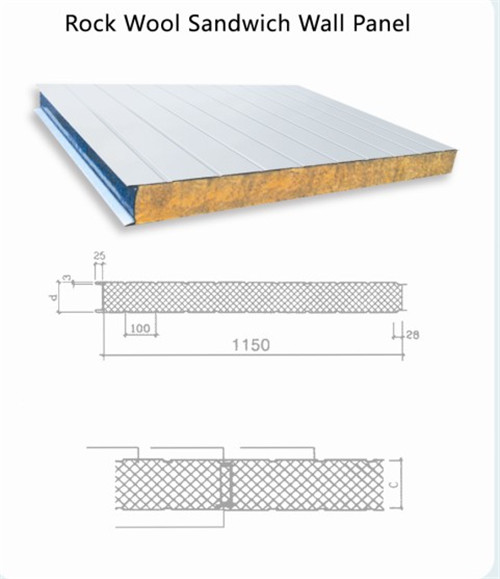

| Panel Material: | Metal | Type: | Rock Wool Sandwich Panels | Thickness: | 50/75/100/125/150/200 mm |

| Color: | Many color are available, but white grey, sea blue and bright red | Materials: | Rockwool, EPS, PU sandwich and two sides are oosteel sheet | Certification: | ISO9001&ISO14001 |

| Name: | sandwich panel; coposite panel;steel plastic composite pannel | Length: | as your require | Effective width: | 950/1150mm for wall or ceiling or 950mm as roof |

| Utilisation: | prefabricated house, container house,cold room | Kinds: | roof panels; wall panels | Charastic: | heat perservation; waterproof |

| Packaging Detail: | standard export pallet,with protective corner guard and film on the four sides |

| Delivery Detail: | 15 days after recieved despoit |

EPS composite board rockwood composite board glassfiber composite board

Light weight

High intensity Sound proof Easy installat

EPS composite board rockwood composite board glassfiber composite board

The usual sandwich panels include rock wool Sandwich panel, EPS sandwich panels, PU Sandwich Panel, glass fiber sandwich pannels. The up & down surface of this panel is Galvanized & Prepainted steel sheets, core material is rock rood, EPS, PU, and glass fiber. It is formed by heating, foaming & laminating. It is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Specifications

(1)Core Material: Rock Wool, EPS, PU; Surface Materials: Galvanized Steel sheets or Prepainted Steel sheets.

(2)Wall Thickness: 40, 50, 60, 80,100,120,150,180,200,250mm

(3)Max. Width: 1200mm

(4)Length: according to client's demands, engineering requirements and shipment conditions

(5) Application: for ceiling & wall, partition wall

(6) Widely used in common steel structure and storey adding projects,e.g. adding storey to small steel structure industrid factory building worehouse,suburbon temporary office,residentid quarters,school,hospital,etc.

Characteristics

1) With a light weight, a giraffe fitting and random incise characteristic, the fitting is much simpler, and it can advance the benefit and save the time limit for a project

2) Color coated sandwich panel's surface material and heat preservation material are non-burn or hard-burn materials, entirely satisfy the fireproofing criterion request

3) Manifold disquisition and oversea used approving more than 40 years. By especial coated dispose, the color coated steel panel's guaranty is 10-15 years, and the panel's life express 35 years by painting the antisepsis material after each 10 years

4) Pressing steel panel with the clear line, and many colors for choice, and suit with any different building style materials, achieving the satisfying effects.

5) In common use heat preservation materials are rock-wool, polystyrene,

polyurethane, all with lower thermal conductivity and favorable heat preservation and heat insulation effects

6) Sound insulation intension can be 40-50dB, it is the most effective sound insulation material

7) Pressing steel panel can be arbitrariness incise, it can satisty the especially design demands

8) Use the high strength steel panel for the base metal (contradict open and pull intension 5,600kg/cm2), adding the most advanced design and roll pressing moulding, it gets the best structure character

9) Improves speediness and springiness designs according to clients' requirements.