Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:1 unit/month

Forklift Description:

Electronic control system by the Italian ZAPI, mature and reliable electronic control system, electrical control installation using fully enclosed structure to ensure the electronic control and hydraulic components from contamination and water splash.

Key vehicle components, from the electronic control, instrumentation to the safety switches are well-known imported brands, key components through a rigorous reliability tests to ensure the stability of overall performance.

Wide view of the door frame design and optimization of the door frame structure, so that a more open view of the operator, operating efficiency and safety can be improved.

Spacious room for maneuver, adjustable steering wheel and seat, the operator can choose the best driving position.

Rational distribution of the control system, fully embodies the principles of ergonomics to improve comfort and reduce operator’s labor intensity.

Forklift safety

Driver safety

In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

Forklift Specification:

| Specifica tion | Model | Unit | CPD20 | CPD25 | CPD30 | |||

| Drive type | ZAPI AC | CURTIS DC | ZAPI AC | CURTIS DC | ZAPI AC | CURTIS DC | ||

| Capacity | kg | 2000 | 2000 | 2500 | 2500 | 3000 | 3000 | |

| Load centre distance | mm | 500 | 500 | 500 | 500 | 500 | 500 | |

| Lift height | mm | 3000 | 3000 | 300 | 3000 | 300 | 3000 | |

| Free lift | mm | 160 | 160 | 160 | 160 | 165 | 165 | |

| Fork size(L*W*T) | mm | 1070*122*40 | 1070*125*45 | |||||

| Mast tilt(forward/backward α°/β°) | Deg | 6/12 | ||||||

| Dimensions | Length | mm | 2375 | 2375 | 2400 | 2400 | 2615 | 2615 |

| Width | mm | 1150 | 1230 | |||||

| Height(mast lowered) | mm | 2010 | 2075 | |||||

| Mast extended height (with safeguard) | mm | 3990 | 3990 | 3990 | 3990 | 4100 | 4100 | |

| Overhead load guard height | mm | 2110 | 2110 | 2110 | 2110 | 2150 | 2150 | |

| Min turning radius | mm | 2080 | 2080 | 2100 | 2100 | 2280 | 2280 | |

| Front overhang | mm | 465 | 465 | 465 | 465 | 485 | 485 | |

| Tread(F/B) | mm | 960/950 | 1000/980 | |||||

| Min ground clearance | mm | 125 | 125 | 125 | 125 | 130 | 130 | |

| wheelbase | mm | 1500 | 1500 | 1500 | 1500 | 1680 | 1680 | |

| Fork adjustable (Max/Min) | mm | 250/1040 | 250/1100 | |||||

| 1000×1200 crossways | mm | 3810 | 3810 | 3830 | 3830 | 4035 | 4035 | |

| 800×1200 lengthways | mm | 3940 | 3940 | 3960 | 3960 | 4165 | 4165 | |

| Performan ce | Travel speed(laden) | km/h | 12 | 11 | 12 | 11 | 12 | 12 |

| Travel speed(unladen) | km/h | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 13 | |

| Up speed(laden) | mm/s | 290 | 220 | 290 | 220 | 250 | 220 | |

| Down speed(unladen) | mm/s | 440 | 360 | 440 | 360 | 400 | 384 | |

| Gradeability(laden/unladen) | % | 15/15 | 15/15 | 15/15 | 15/15 | 15/15 | 15/15 | |

| N.W(Inc. battery) | kg | 4130 | 4130 | 4300 | 4300 | 5060 | 5060 | |

| Tyre(FrontX2) | 7.00-12-12PR | 28x9-15-12PR | ||||||

| Tyre(RearX2) | 18x7-8-14PR | 18x9-8-14PR | ||||||

| Drive motor | Travel motor | kw | 11 | 7 | 11 | 7 | 12 | 10 |

| Lift motor | kw | 11 | 10 | 11 | 10 | 7.4 | 10 | |

| Travel motor*2 | kw | ── | ── | ── | ── | ── | ── | |

| Lift motor*2 | kw | ── | ── | ── | ── | ── | ── | |

| Battery (standard) | V/Ah | 48/620 | 48/600 | 48/620 | 48/600 | 80/500 | 80/500 | |

| Controller | Type | AC | DC | AC | DC | AC | DC | |

| Manufacturer | ZAPI | CURTIS | ZAPI | CURTIS | ZAPI | CURTIS | ||

| Others | Operating pressure for attachment | Mpa | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 |

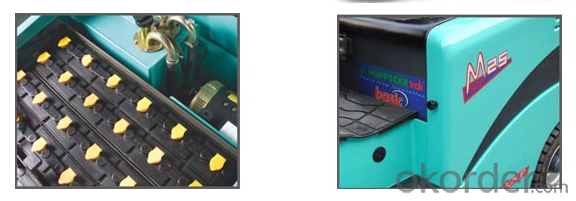

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.