Loading Port:Lianyungang

Payment Terms:TT OR LC

Min Order Qty:50 m³

Supply Capability:100000 m³/month

SIZE:1220X2440;1250X2500 , ETC.

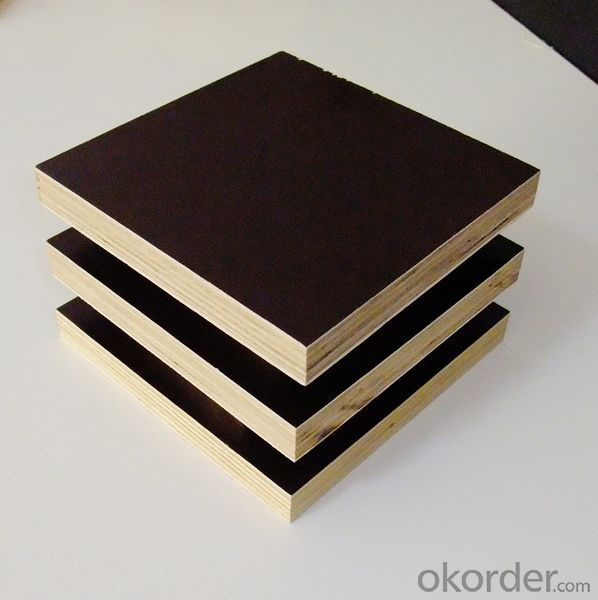

2.BLACK/BROWN/RED FILM

3.CORE:POPLAR/COMBI/HARDWOOD

4.GLUE:MR/MELAMINE/WBP/REAL PHENOLIC

Description

Product Name | WBP/ melamine glue 18mm brown/black film faced plywood |

F/B | Black film, brown film, red film, anti-slip film |

Grade | first grade AAA |

Core | Poplar, hardwood,combi, Eucalyptus, birch,Pine |

Glue | Melamine/WBP/MR |

Thickness | 12mm,13mm,14mm,15mm,16mm,17mm,18mm |

Specification | 915MMX1830MM,1220X2440mm |

Moisture Content | 14%-18% |

Package | Seaworthy packing |

MQQ | 1X20’GP,22CBM |

Price terms | EXW, FOB, CNF, CIF |

Payment | T/T, L/C at sight |

Delivery time | Usually 15 days after receipt of the original L/C or the 30% advanced payment |

Supply Capacity | 3000 CBM/Month |

Usages: | Can be widely used for building concrete, etc |

Remarks: | Top class equipment with top class produce technique; Credit first, Fair trading |

Features

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

FAQ

1.free samples are available

2.MOQ is one 40HQ container

3.delivery time 30 days after getting deposit

4.payment term T/T or L/C at sight