Loading Port:China Main Port

Payment Terms:TT or L/C

Min Order Qty:USD3000 roll

Supply Capability:Ten Containers Per Month roll/month

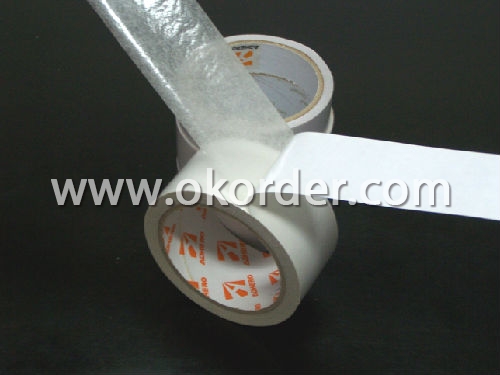

General Information of Double Sided Tissue Tape DSW-90HH

1. Applications:

Courier envelope sealing, flying splice operations on papers and cardboard, leather and fabric bonding and positioning in shoe and baggage industry, sheet fixing and bonding in toy industry, stationery, advertisement, computer embroidery, packaging and foam laminating.

2. The products should be stored at room temperature and be kept away wet and/or heat source.

3. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

4. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

5. Special requirements will be satisfied after communications.

Technical Data of Double Sided Tissue Tape DSW-90HH

CONSTRUCTION:

Carrier: Tissue paper

Adhesive: Water based acrylic

Liner: Silicone release PE-coated paper, white colour.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + tissue): 90 ± 5 micron

Initial Tack (14# steel ball): ≤120 mm

Peel Adhesion (Kg/25mm): 1.2 ± 0.2 Kg

Holding power: ≥ 500 min

Temperature resistance: 80C

PACKING of Double Sided Tissue Tape DSW-90HH

Core I.D.: 3” (76mm±1)

Jumbo Roll:1.02 x 1000m; 1.24 x 1000m

Packaging:Wrapped with corrugated cardboard.

Cut Roll: roll width 3mm up

Remarks of Double Sided Tissue Tape DSW-90HH

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.