Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

Features of Multi-layer Co-extrusion Greenhouse Film Blowing Machine

The lines is researched and designed on the basis of introducing and learning and assimilating the advanced key technology of Europe and America. It can be used for precess LDPE, LLDPE, MLLDPE, EVA, HDPE, etc. The line has various advantages such as Proper structure, stable function, nice plasticization, high output, low energy consumption and clear layers. It is the perfect device produce wide greenhouse film and geomembrane which have various function such as high strength, aging-resisting, non-fogdrop, light filtering and heat insulating.

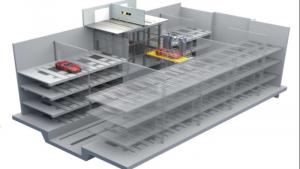

Three-layer Coextrusion Film Blowing Machine (4-10m)

Main technical details:

1. Film Thickness: 0.05-0.2mm

Film Open Width: 4000-10000mm

Material: MLLDPE, LDPE, LLDPE, EVA

2. Material Mi range

1) LDPE: Mi=0.3-2.0

2) LDPE: Mi=0.3-2.0 EVA(5%~14%)

3) Mixed material (LLDPE and LDPE)

3. Single screw extruder:SJ120/30 (3 sets)

1) Capacity: 750kg/h

2) Screw Type: Wave type and mixed smelted head, used for processing of many material.

3) Screw Diameter: Φ 120mm (3 sets)

4) Screw L/D: 30: 1

5) Screw Material: 38CrMoALA\Nitrogen treated

6) Nitrogen treatment depth: 0.4-0.7mm, Surface hardness≥ HV950

7) Barrel Material: 38CrMoALA\Nitrogen treated

8) Processing Technics: Forging, Nitrogen HV≥ 750

9) Nitroged thickness: 0.4-0.7mm

10) Barrel temeperature controll: Constant temperature auto-controll

11) Barrel heating method: Cast aluminum heating

Barrel cooling method: Air-cooling

4. Gearbox: (Special for Plastic Machinery)

1) Gear Type: Standard hard gear

2) Gear Material: 20CrMoTi

3) Gear case lubricating method: Forcing oil lubricating

4) Main motor power: SJ120/30 with 132kw,

Three-phase asynchronism motor,

Frequency conversion

5) Equipped with long-acting screen changer equipment, to prolong screen changer

6) 120 Long-acting screen changer 3sets

5. Diehead

1) Sepecification: 1200× 2.0 (1 set)

2) Type: Three-layer coextrusion inner composite spiral die

3) Installation Method: Railway type diehead dolly

4) Heating Method: Casting aluminum heater

5) Temperature Controll: Auto-controll

6. Air Ring Equipment

1) Out Air Ring: 1 set

2) Air Ring Type: Double wind-nozzles structure

3) Cooling winder power: 22kw

4) Rotate Speed: 2900 rpm

5) Air pressure: 8000Mpa

6) Air capacity: > 3297m3/h

7. Inner Cooling Air Ring

Inner cooling controll system with PLC, It can improve the transparency and quality of film.

1) Controll system: PLC controll system, LCD Screen

2) Inner cooling blower: 2 sets, Frequency conversion timing

3) Intowinder: 15kw

4) Outwinder: 15kw

5) Imported ultrasonic sensor: 2 PCS

8. Haul off equipment

1) Upper haul off height: 21m

2) Die operation plat: 1 set

3) Triangle type frame: Steel frame rolling type 1 set

4) Flash board: Rolling type 1 set

5) Steady foam equipment: Rolling type 1 set

6) Upper haul off equipment: 1PC/set

7) Haul off roller sepecification: 340× 3200mm Speed: 0.5-15m/min

8) Motor power: 5.5kw

9. Tightening equipment and winding equipment: 1 set

1) Haul off roller sepecification: 200× 3200mm

2) Haul off Speed: 0.5-20m/min

3) Winding Method: Surface friction furl

4) Winding Speed: 0.5-20m/min

5) Winding motor type: YLJ132-40/6

10. The standard of checking machines

The machines will be fit for the standard as follows,

1) JB/T8061-96 Single screw plastic extruder

2) JB/78538-1997 Screw and Barrel equipped plastic machinery

3) JB/T8703-98 Plastic film blowing down-equippment

4) GB4340-84 The test method of metal hardness

5) GB11354-89 The standard of steel parts

6) GB11379-89 The standard of plating chrome

7) GB985-88 The type and size of welding

8) ZBG950/0-88 The condition and standard of painting