Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

Cast resin dry-type transformers

1. Features

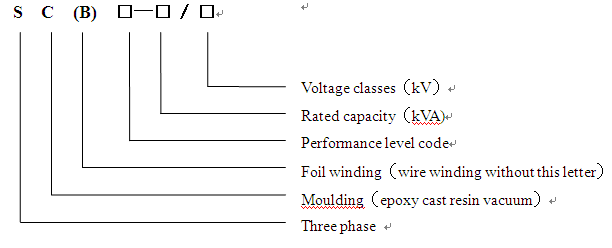

SC(B) Series Cast Resin Dry type Transformers (CRDT) are produced by using full auto vacuumcast transformer software technology of thin insulating tape filling from Germany HTT MASCHINEN GMBH, full-auto vacuum cast equipment from GermanyHeydrich GMBH, High-Low voltage foil winding machine from France BR company,full-auto silicon steel sheet cut-to-length line from Germany GEORG GMBH, highquality epoxy cast resin materials and high-permeability grain-oriented cold rolled silicon steel sheets. Based on advanced technology, raw materials with high quality, scientific management and complete inspection manners, the features of the product are as follows:

Coils are covered by glass fiber and moulded by epoxy cast resin material under vacuum,which has the advantages of perfect mechanical performance, no cracking, nobubbles inside, little partial discharge, high reliability and long servicelife.

Better humidity resistance. CRDT can be operated in severe environment and high humidity by reasons that HV&LV coils adopt high-temperature moulding structure with low hygroscopic and clamps for core are anti-corrosion.

Flame retardance, explosion proof and friendly environment. Insulation materials (such as glass fiber) used for coil are not very flammable and can be self-extinguishing,electric arc resulted from short-circuit cannot start a fire. There are nohazardous fire gases from resin under high temperature.

Thin insulation structure and air flues inside can strengthen heat emission and short-circuitoverload capacity.

Low loss and low noise. Core lamination adopts 45° full sloping seam and four orseven level step-by-step system, which improves efficiently the magnetic fluxdistribution at the corner of iron core and reduces no-load loss and noiselevel.

Excellent ability to withstand short circuit and lightning impulse.

Smallsize, light weight, simple installation and free maintenance.

2. Standard

National standard GB1094.11 "Power transformer Part 11: Dry type transformer"

National standard GB10228 "Technical parameters &requirements for dry-type power transformer"

IEC 60076-11 "Power transformer Part 11: Dry type transformer"

DIN 42532 "Cast resin dry-type power transformer"

Machinery industry standard JB/T3837 "Productmodel compilation method for transformer"

Machinery industry standard JB/T10088 " 6kV- 500kV Power transformer sound level"

3. Technical specification

Voltage class: 10~35kV

Capacity range: 30~3150kVA

Voltage regulating mode: no excitation voltage regulation

Tappingrange: ±2×2.5%or ±5%

Frequency:50Hz or 60Hz

Connection symbol: Yyn0 or Dyn11

Short-circuit impedance: standard impedance (See technical parameters)

Peak temperature rise: 100K

Cooling model: AN or AF

Protection level: indoor: IP00, IP20, IP23

Insulation class: class F

Insulation level: 10kV power frequency withstand voltage 35/3kV impact withstand voltage75kV,

35kV power frequency withstand voltage 70 kV impact withstand voltage 145 kV

4. Model coding

5. Operating condition

Ambient temperature: maximum temperature 40 ℃, minimum temperature -5 ℃ (applicable toindoor type transformer), or else based on GB1094.11-2007 and the relevantprovisions

Environmental condition: no harmful smog and steam, no excess corrosive dust, vapor, salt fog,no serious damp and dripping water.

Altitude: less than 1000m, otherwise adjust appropriately in accordance with therelevant provisions.

Insulation class: class F, temperature limit of 155 ℃.

Power waveform and frequency: three-phase power supply voltage approximates symmetry, powerwave approximates sine wave, frequency 50 Hz or 60 Hz.

6. Technical parameter and overall dimension

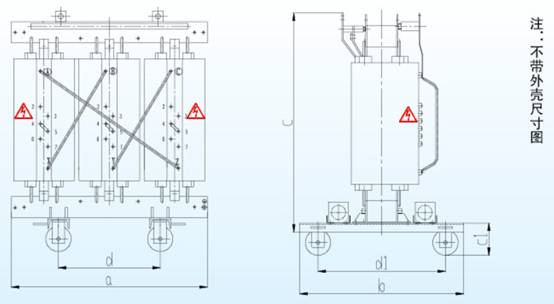

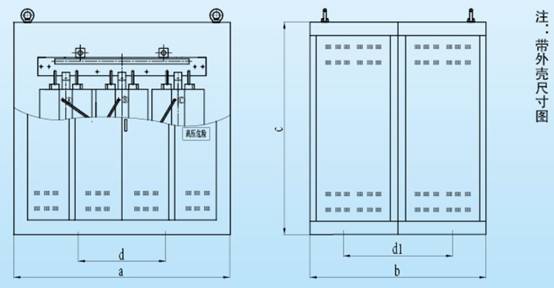

Dimension drawing without enclosure

Dimension drawing with enclosure

SC (B)9 series 10kV power transformers

Model | Rated Capacity(kVA) | Rated Voltage (kV) | Loss (W) | Short-circuit impedance (%) | No-load current (%) | Connection symbol | Weight(kg) | Overall dimension (mm) L×W×H | Track gauge (mm) | ||

HV | LV | No-load | Load 120℃ | ||||||||

SC9-20/10 | 20 | 6 6.3 6.6 10 10.5 11 | 0.4 | 190 | 650 | 4 | 3.4 | Dyn11 Yyn0 | 230 | 570×600×730 | 300/300 |

SC9-30/10 | 30 | 220 | 750 | 2.4 | 270 | 600×600×740 | 300/300 | ||||

SC9-50/10 | 50 | 310 | 1060 | 2.4 | 360 | 660×600×770 | 300/400 | ||||

SC9-6310 | 63 | 350 | 1230 | 2.4 | 410 | 680×600×770 | 300/400 | ||||

SC9-80/10 | 80 | 420 | 1460 | 2.0 | 490 | 680×600×870 | 300/400 | ||||

SC9-100/10 | 100 | 450 | 1670 | 1.8 | 580 | 700×700×910 | 300/400 | ||||

SC9-125/10 | 125 | 530 | 1960 | 1.6 | 630 | 940×850×1180 | 520/520 | ||||

SC9-160/10 | 160 | 610 | 2250 | 1.6 | 770 | 1110×950×1300 | 520/520 | ||||

SC9-200/10 | 200 | 700 | 2680 | 1.4 | 880 | 1110×950×1350 | 520/520 | ||||

SCB9-250/10 | 250 | 810 | 2920 | 1.4 | 1100 | 1180×1150×1460 | 520/520 | ||||

SCB9-315/10 | 315 | 990 | 3670 | 1.2 | 1190 | 1230×1150×1480 | 660/880 | ||||

SCB9-400/10 | 400 | 1100 | 4220 | 1.2 | 1470 | 1250×1150×1520 | 660/880 | ||||

SCB9-500/10 | 500 | 1310 | 5170 | 1.2 | 1700 | 1250×1150×1550 | 660/880 | ||||

SCB9-630/10 | 630 | 1510 | 6220 | 1 | 2040 | 1360×1150×1600 | 660/880 | ||||

SCB9-630/10 | 630 | 1460 | 6310 | 6 | 1 | 2010 | 1420×1150×1620 | 660/880 | |||

SCB9-800/10 | 800 | 1710 | 7360 | 1 | 2420 | 1480×1250×1670 | 820/1000 | ||||

SCB9-1000/10 | 1000 | 1990 | 8610 | 1 | 2780 | 1570×1250×1760 | 820/1000 | ||||

SCB9-1250/10 | 1250 | 2350 | 10260 | 1 | 3200 | 1740×1250×1800 | 820/1000 | ||||

SCB9-1600/10 | 1600 | 2760 | 12400 | 1 | 3800 | 1850×1350×1840 | 820/1070 | ||||

SCB9-2000/10 | 2000 | 3400 | 15300 | 0.8 | 4400 | 1900×1450×1930 | 1070/1200 | ||||

SCB9-2500/10 | 2500 | 4000 | 18180 | 0.8 | 5650 | 2130×1450×2050 | 1070/1200 | ||||

SC(B) 10 series 10kV power transformers

Model | Rated capacity (kVA) | Rated voltage (kV) | Loss (W) | Short-circuit impedance (%) | No-load current (%) | Connection symbol | Weight(kg) | Overall dimension (mm) L×W×H | Track gauge (mm) | ||

HV | LV | No-load | Load 120℃ | ||||||||

SC10-20/10 | 20 | 6 6.3 6.6 10 10.5 11 | 0.4 | 170 | 620 | 4 | 3.4 | Dyn11 Yyn0 | 230 | 570×600×730 | 300/300 |

SC10-30/10 | 30 | 190 | 710 | 2.4 | 270 | 600×600×740 | 300/300 | ||||

SC10-50/10 | 50 | 270 | 1000 | 2.4 | 360 | 660×600×770 | 300/400 | ||||

SC10-63/10 | 63 | 320 | 1170 | 2.0 | 410 | 680×600×770 | 300/400 | ||||

SC10-80/10 | 80 | 370 | 1380 | 1.8 | 490 | 680×600×870 | 300/400 | ||||

SC10-100/10 | 100 | 400 | 1570 | 1.8 | 580 | 700×700×910 | 300/400 | ||||

SC10-125/10 | 125 | 470 | 1850 | 1.6 | 660 | 950×850×1200 | 520/520 | ||||

SC10-160/10 | 160 | 540 | 2130 | 1.6 | 810 | 1110×950×1320 | 520/520 | ||||

SC10-200/10 | 200 | 620 | 2530 | 1.4 | 930 | 1110×950×1370 | 520/520 | ||||

SCB10-250/10 | 250 | 720 | 2760 | 1.4 | 1250 | 1180×1150×1480 | 520/520 | ||||

SCB10-315/10 | 315 | 880 | 3470 | 1.2 | 1280 | 1260×1150×1500 | 660/880 | ||||

SCB10-400/10 | 400 | 980 | 3990 | 1.2 | 1500 | 1280×1150×1550 | 660/880 | ||||

SCB10-500/10 | 500 | 1160 | 4880 | 1.2 | 1750 | 1280×1150×1610 | 660/880 | ||||

SCB10-630/10 | 630 | 1340 | 5880 | 1 | 2080 | 1400×1150×1635 | 660/880 | ||||

SCB10-630/10 | 630 | 1300 | 5960 | 6 | 1 | 2060 | 1450×1150×1650 | 660/880 | |||

SCB10-800/10 | 800 | 1520 | 6960 | 1 | 2500 | 1500×1250×1710 | 820/1000 | ||||

SCB10-1000/10 | 1000 | 1770 | 8130 | 1 | 2950 | 1600×1250×1800 | 820/1000 | ||||

SCB10-1250/10 | 1250 | 2090 | 9690 | 1 | 3450 | 1770×1250×1840 | 820/1000 | ||||

SCB10-1600/10 | 1600 | 2450 | 11730 | 1 | 4000 | 1890×1350×1890 | 820/1070 | ||||

SCB10-2000/10 | 2000 | 3050 | 14450 | 0.8 | 4650 | 1940×1450×1970 | 1070/1200 | ||||

SCB10-2500/10 | 2500 | 3600 | 17170 | 0.8 | 5900 | 2170×1450×2100 | 1070/1200 | ||||

SC(B) 11 series 10kV power transformers

Model | Rated capacity (kVA) | Rated voltage (kV) | Loss (W) | Short-circuit impendence (%) | No-load current (%) | Connection Symbol | (kg) Weight without enclosure

| (kg) Weight with enclosure | (mm) Dimension (no enclosure) L×W×H | (mm) Dimension ( with enclosure) L×W×H | Track gauge (mm) | ||

HV | LV |

No-load | Load 120℃ | ||||||||||

SC11-20/10 | 20 | 6 6.3 6.6 10 10.5 11 | 0.4 | 150 | 620 | 4 | 3.4 | Dyn11 Yyn0 | 230 | 145 | 570×600×730 | 1100×1100×1200 | 300/300 |

SC11-30/10 | 30 | 175 | 710 | 2.4 | 270 | 145 | 600×600×740 | 1100×1100×1200 | 300/300 | ||||

SC11-50/10 | 50 | 250 | 1000 | 2.4 | 360 | 145 | 660×600×770 | 1100×1100×1200 | 300/400 | ||||

SC11-63/10 | 63 | 280 | 1170 | 2.0 | 410 | 145 | 680×600×770 | 1100×1100×1200 | 300/400 | ||||

SC11-80/10 | 80 | 335 | 1380 | 1.8 | 490 | 145 | 680×600×870 | 1100×1100×1200 | 300/400 | ||||

SC11-100/10 | 100 | 360 | 1570 | 1.8 | 580 | 145 | 700×700×910 | 1100×1100×1200 | 300/400 | ||||

SC11-125/10 | 125 | 425 | 1850 | 1.6 | 680 | 200 | 980×850×1230 | 1400×1200×1600 | 520/520 | ||||

SC11-160/10 | 160 | 490 | 2130 | 1.6 | 830 | 200 | 1150×950×1380 | 1400×1200×1600 | 520/520 | ||||

SC11-200/10 | 200 | 560 | 2530 | 1.4 | 960 | 215 | 1150×950×1420 | 1600×1200×1700 | 520/520 | ||||

SCB11-250/10 | 250 | 650 | 2760 | 1.4 | 1280 | 240 | 1230×1150×1510 | 1600×1400×1700 | 520/520 | ||||

SCB11-315/10 | 315 | 790 | 3470 | 1.2 | 1320 | 240 | 1300×1150×1540 | 1600×1400×1700 | 660/880 | ||||

SCB11-400/10 | 400 | 880 | 3990 | 1.2 | 1550 | 260 | 1320×1150×1590 | 1700×1400×1800 | 660/880 | ||||

SCB11-500/10 | 500 | 1050 | 4880 | 1.2 | 1800 | 270 | 1320×1150×1650 | 1700×1400×1900 | 660/880 | ||||

SCB11-630/10 | 630 | 1210 | 5880 | 1 | 2130 | 280 | 1450×1150×1680 | 1800×1400×1900 | 660/880 | ||||

SCB11-630/10 | 630 | 1170 | 5960 | 6 | 1 | 2120 | 280 | 1480×1150×1690 | 1800×1400×1900 | 660/880 | |||

SCB11-800/10 | 800 | 1370 | 6960 | 1 | 2560 | 310 | 1550×1250×1760 | 2000×1500×2000 | 820/1000 | ||||

SCB11-1000/10 | 1000 | 1590 | 8130 | 1 | 3000 | 325 | 1650×1250×1850 | 2100×1500×2100 | 820/1000 | ||||

SCB11-1250/10 | 1250 | 1880 | 9690 | 1 | 3510 | 335 | 1820×1250×1900 | 2200×1500×2100 | 820/1000 | ||||

SCB11-1600/10 | 1600 | 2210 | 11730 | 1 | 4100 | 380 | 1940×1350×1940 | 2300×1600×2300 | 820/1070 | ||||

SCB11-2000/10 | 2000 | 2720 | 14450 | 0.8 | 4750 | 400 | 1990×1450×2000 | 2400×1700×2300 | 1070/1200 | ||||

SCB11-2500/10 | 2500 | 3200 | 17170 | 0.8 | 6000 | 430 | 2220×1450×2150 | 2500×1700×2500 | 1070/1200 | ||||

Note:All pictures and datum of the products in it are only for your reference, we reserve the right of changing and updating the content, picturesand datum in this paper without prior notice.

7. Temperature control system

The safe operation and service life largely depends on security and reliability of winding’s insulation. When winding temperature is beyond insulation tolerable temperature, the insulation is damaged, which is the main reason that may lead to the transformernot be normally used. BWD3K series temperature control system measures thetemperature of LV winding by PTC temperature measurer and can control coolingfan according to the measured temperature values.

Features:

Integrating of temperature display and control.

The advanced circuit design can effectively restrain circuit drift, andhas strong anti-interference ability

Has Watch Dog function and power failure detection circuit on powersupply to make sure that the thermostat can work well in harsh environment.

According to user requirements to provide the three-phasetemperature value 4-20mA analog output function and RS232 or RS485 computer interface, to meet the requirements of automatic monitoring.

Simple and practical draw type installation, easy to remove.

Main functions:

1.Three-phase winding temperature data-loggingand maximum value display.

2.Automatic open and close fanfunction/manual start-stop function according to set temperature

3.Over-temperature alarm, over temperaturetrip function.

4. Fault detection alarm, mute function.

5. Fan start-stop function on a regularbasis.

* 6. Output and temperature synchronous 4 ~20A standard value electric current.

* 7. RS232 or RS485 computer interface output,communication distance reaches 1200 meters.

Note: "*" is optional.

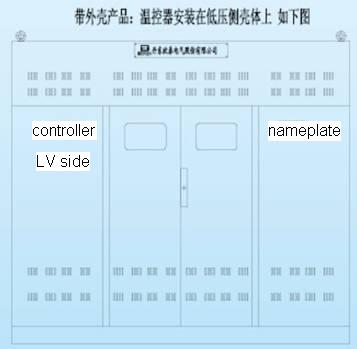

Product with enclosure: Thecontroller is installed at the LV side.

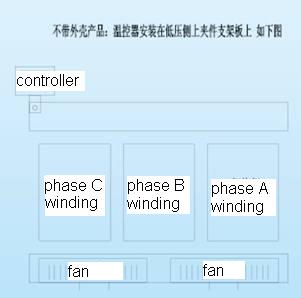

Product without enclosure: Thecontroller is installed on the clamp supporting plate at the LV side.

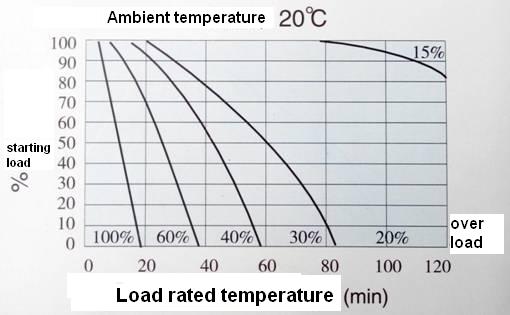

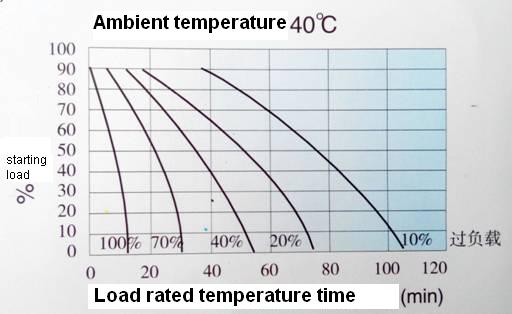

8. Overload capacity curve