Loading Port:Xingang Port

Payment Terms:TT or L/C

Min Order Qty:1 Unit set

Supply Capability:100Set Per month set/month

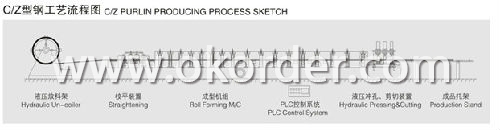

This machine is full-automatically controlled by PLC,the whole hydrau-lic transmission,drive hydraulic oil jar carry out and shear through centre pump station towarde the hole,hydraulic pressure motor trans-mit power as main transmission,characteristics. It is reliable to oper-ate steadily by hydraullc prdssure,Shear towards hole precision high,high output,low energy consumption,Section geometry form rule of the notch,Its hydraulic pressure trausmission ,two sets of rectification correct and fit,the cut-off have a national patent.

We can produce according to your drawing.

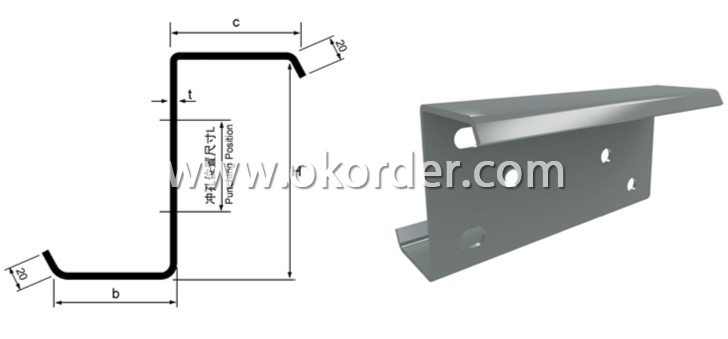

Main Technical Parameter of Z -Section Forming Machine

Number | Item | Specification | Unit/Type |

1 | Main roll forming machine model | Z |

|

2 | Rack structure | wall plate structure or column structure |

|

3 | Raw material | galvanized steel or color-coated plate |

|

4 | Original width | / | mm |

5 | Cover width | / | mm |

6 | Thickness of panel |

1.5-3.0mm | mm |

7 | Yield strength | 250 | Mpa |

8 | Forming speed | 0-15 | m/min |

9 | Main Motor Power | 30KW | KW |

10 | Roller material | 45# forged steel, polished and surface coated with Chrome |

|

11 | Main shaft material | 45# fine steel, Quenching and Tempering heat treatment |

|

12 | Roll Stand | 16 | mm |

13 | Spec | 140-300 |

|

14 |

Waist Height: |

50-90mm |

|

15 | Hydraulic pressure | 12 | Mpa |

16 | Power supply | depend on customer's requirement |

|

17 | Cutter material | Cr12 |

|

18 | Electrical control system | Panasonic PLC |

|

19 | Cutting method | hydraulic cutting, automatically cut to length after roll forming |

|

20 | Color of the machine | depend on customer |

|

21 | Container needed | 1x40 | GP |

Producing Process Sketch of Z -Section Forming Machine

Application of Z -Section Forming Machine

Packaging & Delivery of Z -Section Forming Machine

Packaging Detail: | 1*40GP CONTAINER |

Delivery Detail: | 30 days |