Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 pc

Supply Capability:200 pc/month

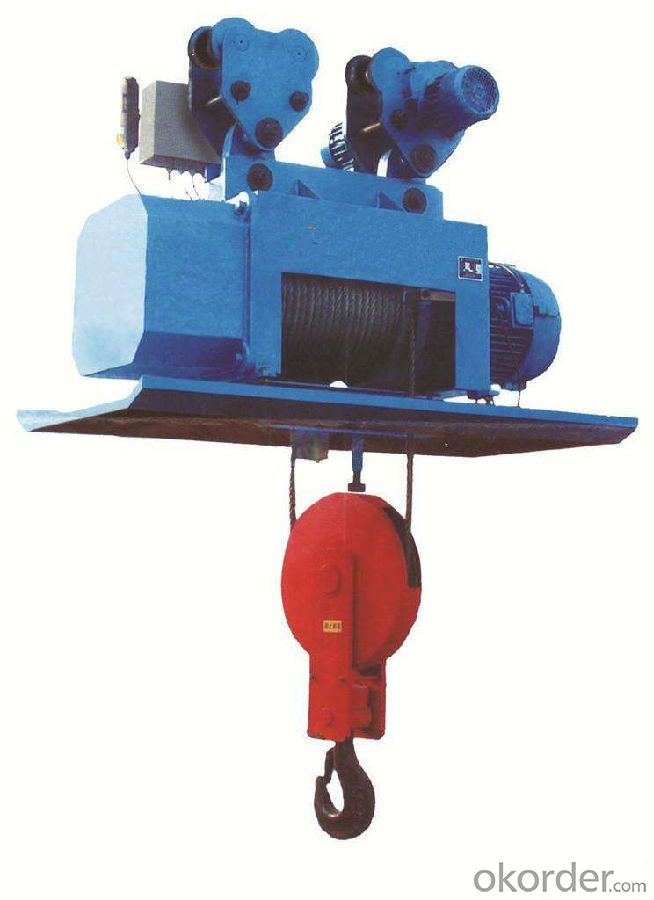

The brief description of the YH metallurgy electric hoist

1. YH series metallurgic electric hoist is mainly used to lift metallurgic crane which is for molten mental. Lifting capacity is ≦20m. Working environment temperature is -10℃-60℃. Relative humidity is no more than 50% in 40℃ working temperature.

2.Protective functions include double brake, double restrict and insulation board.

3. Metallurgical electric hoist can work with single beam as well as fixed hanged rail alone which is installed in workshop. It is a kind of ideal light metallurgic lifting equipment.

4. Design and manufacture of metallurgic lifting equipment conforms to the document No.ZJBT【2007】375 which is issued by General Administration of Quality Supervision.

5.Other materials which include lifting molten non-metallic material and red-hot solid metal also can refer to the metallurgical electric hoist.

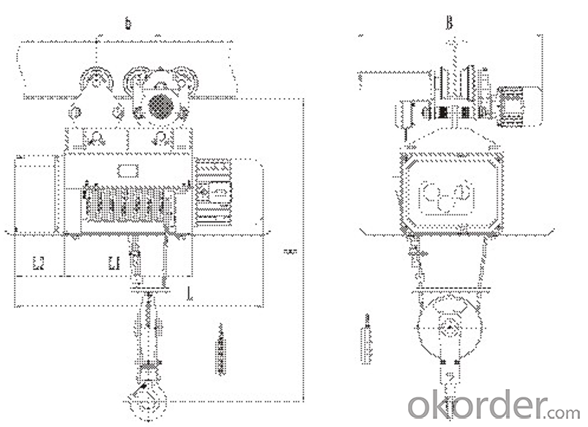

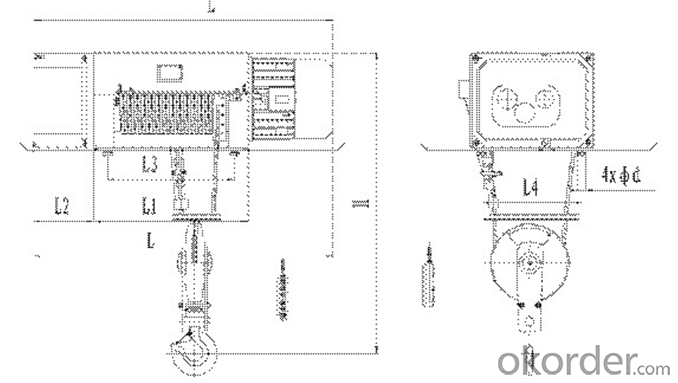

YH 2-5T H=9-20 M

Model YH Stationery 2-5 T (H=9-20M)

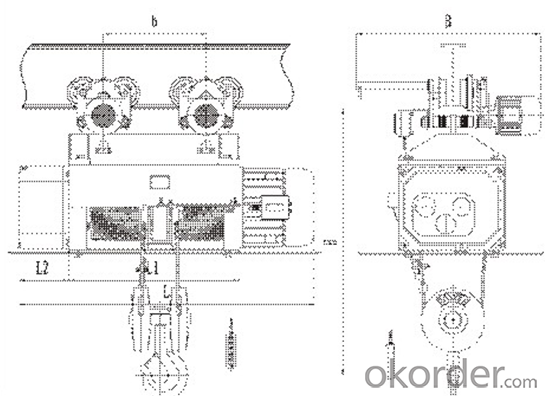

Model YH 10T (H=9-20m)

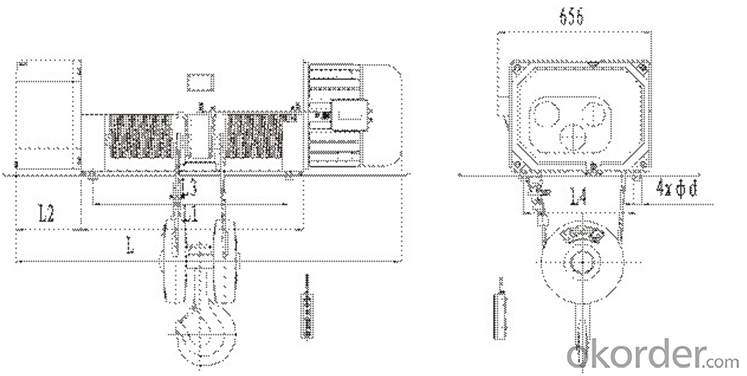

Model YH Stationery 10T(H=9-20m)

The details of the YH metallurgy electric hoist

This electric hoist is developed on basis of CD1, MD1 WH164. It holds compact structure, reasonable layout, safe reliability, convenient maintenance, excellent swelling function advantages, which makes its application scope wider, becoming ideal lifting equipment in factories, mines, agriculture, electric power, construction building site, dock and warehouse for installation of the machines, lifting the cargo, loading and unloading the trucks.

YH metallurgy electric hoist has the features as below:

1. Product Name/Model: YH metallurgy electric hoist

2. Designed and developed with the FEM standard, advanced idea and beautiful exterior.

3. The drive units use China's advanced point-line meshing gear structure. It is easy and convenient to handle with the compact and reasonable whole structure.

4. It is safe and efficient to operate, and meet current requirements of low noise and environmental protection.

5. Using 13 proprietary technologies and utilize frequency control design to reduce the impact force to accomplish precise positioning.

6. Equipped with intelligent safe operation monitoring recorder like the "black box" on plane which can uninterruptedly record working status and prevent unprofessional operations.

7. Maintenance-free design of whole body and less wearing parts make it convenient to maintain.

High Efficiency, Maximized Usage of Space:

Hoist and trolley motors designed for space savings and productivity. Standard two-speed hoist motor (6:1 ratio), designed specifically for hoisting applications, offers high starting torque and ensures precise and reliable load handling. The most compact structure makes the application of Zhongan Low Headroom Electric Wire Rope Hoists cover a larger area in the same plant and working area, reducing dead spots. If requirements for the plant is designed according to the parameters, the requireents for the plant height will be significantly lowered, saving investment, improving efficiency and reducing cost for the customers.

Ease of Operation:

Large-diameter hoist drum means easy positioning, closer approaches. The larger drum diameter provides near true vertical lift with a single reeved hoist. The result is exceptionally smooth movement and fast load positioning. This innovative design also means a shorter frame length, allowing closer end approaches.

The hoist motor is class F insulated, 30 minute rated (60% effective duty), thermally protected and totally enclosed.

Safety:

Standard safety features of Low Headroom Electric Wire Rope Hoist including load limit switch prevents the lifting of loads that are in excess of 110% of rated capacity. The 4-position hoist limit switch includes phase mismatch protection circuit preventing the block from running up and damaging the hoist in the event of phase reversal. And there are also phase-loss, voltage-loss, over current etc. safety proection,

Less Maintenance:

Aluminum alloy hoisting motor shell, light weight, anti-corrosion level IP55. The trolley drive is totally enclosed, grease lubricated all service life and is designed to be maintenance-free. The automatic disc brake and inverter control help extend the life of the motor and other components, which means less maintenance, less downtime, lower repair costs - and reduced cost over the lifetime of your hoist equipment.

Long Life:

Compact gearbox provides dependable operation and extends equipment life. The gear case design reduces stress on drum bearings, reducing the need for maintenance while extending component life. It features hardened and ground internal reduction gears driving an external drum gear located on the inner surface of the rope drum. The gearbox's semi-fluid grease lubrication also helps to extend its working life.

We adopt seamless steel drum contain with rope groove. We use high strength linear contact wire rope, safety factor could meet 5 times safety lifting weight, with good anti-grind characteristic, long service life.

Lifting capacity(t) | 2 | 3 | 5 | 10 | ||

Type | YH | |||||

Hoisting height | 9/12/15/18/20 | 9/12/15/18/20 | 9/12/15/18/20 | 9/12/15/18/20 | ||

Hoisting speed(m/min) | 8(2/8) | 8(2/8) | 8(2/8) | 7(1.75/7) | ||

Travel speed(m/min) | 20 | |||||

Wire rope | Diameter(mm) | 11 | 13 | 15 | ||

Specificatioin | 6*37+1WR | |||||

Track | 20a-30c | 25a-50b | 32b-50c | |||

Min. Curvature radius | 2/3/4/5/6 | 2/3/4/5/6 | 2.5/3/4/5/6 | 3.5/4/6 | ||

Type | ZD₁31-4(ZDD41-4/16) | ZD₁32-4(ZDD41-4/16) | ZD₁41-4(ZDD51-4/20) | ZD₁51-4(ZDD52-4/20) | ||

Power | 3.0(3.0/0.75) | 4.5(4.5/1.1) | 7.5(7.5/2.0) | 13(13/3.25) | ||

Rotation speed | 1380/330 | 1380/330 | 1400/330 | 1400/330 | ||

Current (A) | 7.6(7.6/2.3) | 11(11/3.5) | 18(18/5.6) | 30(30/9.4) | ||

Type | ZDY₁12-4 | ZDY₁21-4 | ||||

Power (kw) | 0.4 | 0.8 | ||||

Rotation speed(m/min) | 1380 | 1380 | ||||

Current (A) | 1.25 | 2.4 | ||||

No.of connecting | 300 | |||||

Duty classification | FC=50% | |||||

Power source | Three phase AC 380V50 Hz | |||||

Basic dimension (mm) | 1044/1147/1943/2124/2244 | 1110/1213/2009/2190/2310 | 1256/1356/1461/1561/1631 | 1647/1828/2009/2190/2310 | ||

L1 | 559/662/765/868/939 | 559/662/765/868/939/ | 600/700/805/905/975 | 950/1131/1312/1493/1613 | ||

L2 | 192 | 234 | 272 | 278 | ||

L3 | 439/542/645/748/819 | 439/542/645/748/819 | 439/542/645/748/819 | 825/1006/11871368/1488 | ||

L4 | 362 | 362 | 362 | 348 | ||

b | 205/332/435/539/609 | 205/332/435/538/609 | 228/570/675/775/845 | 574/755/936/1117/1237 | ||

B | 950 | 1055 | ||||

H | 1300 | 1315/1400 | 1590 | 1600 | ||

d | 25 | |||||

Operate | Crane weight (kg) | 439/457/479/494/505 | 475/493/515/530/541 | 679/752/776/794/809 | 1169/1221/12821326/1396 | |

Fix | 409/427/449/464/475 | 445/463/485/500/511 | 644/717/741/759/774 | 1129/1181/1242/1286/1356 | ||