Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1000 m

Supply Capability:1000000 m/month

1. Standard:National Standard GB/T12706-2008/IEC60502,AS/NZS,ICEA, ASTM etc

2. Rated Voltage: U0/U: 0.6/1kV~26/35kV

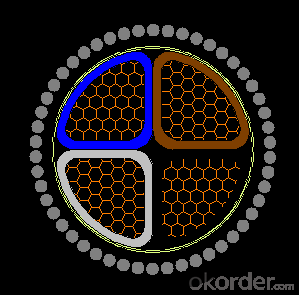

3. Construction :

Conductor | Compact Stranded Copper Conductor, Class 2 as per IEC 60228 |

Circular solid Copper Conductor, Class 1 as per IEC 60228 | |

Flexible Stranded Copper Conductor, Class 5 as per IEC 60228 | |

Conductor Screen | Semi-conductor (MV only) |

Insulation | XLPE(Cross-linked polyethylene) |

Insulation Screen | Semi-conductor (MV only) |

Separate Screen | Copper Tape (MV must, LV optional) |

Filler | PP Yarn, or Paper |

Wrapping Tape | PP |

Inner Covering | Extruded PVC (MV only) |

Armour | Steel Wire, or Steel Tape, or Aluminium Tape optional |

Overall Sheath | PVC or PE |

4. Application:

Suitable for use in power distribution lines or fixed installation with rated voltage between 0.6/1kV~26/35kV

5. Operating Characteristics:

Max.permission conductor continous operating temperature of conductor;90 °C

Max.short-circuit temperature of conductor shall not exceed 250 °C (5s maximum duration)

The ambient temperature under installation of cable should not below 0 °C

The bending radius of a single-core cable should not less than 20 times of outer diameter of the cable

The bending radius of a three-core cable should not less than 15 times of outer diameter of the cable

6. Hengtian cable production line

PVC electrical wire

power cable from low voltage 0.6/1kv to 110kv

PVC insulated PVC sheathed electrical power cable

XLPE insulated PE/PVC sheathed electrical power cable

fire resistance electrical power cable

LSZH electrical power cable

control cable(cable material can be PVC, Fluoroplastic,rubber or with customer design)

Twisted pair shield instrumentation cable

rubber sheathed cable

mining cable

aerial bundled cable

elevator cable

RF coaxial cable

stranded bare conductor

special cable : with our own research and development team, Hengtian cable can work with you on common products but also your new designs.

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.