Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:4 unit/month

MMW-1A microcomputer controlled vertical universal friction and abrasion testing machine

Product description

1. This machine has the friction forms of sliding, rolling or sliding-rolling compound motion under some contact pressures; it has a stepless speed regulating system, and under low speed or high speed conditions, it can evaluate the friction and wear properties of lubricants, metal, plastics, coating, rubber, ceramics and other materials, such as low-speed pin-on-disk (having large disk and small disk, single needle and three-needle) friction function, four-ball long-term antiwear property and four-ball rolling contact fatigue and thrust washer friction performance tests. It can replace American FALEX6 multi-functional testing machine, and it is a testing machine generally adopted by many units engaging in tribology researches, mainly used for tribology performance tests of materials and coating. The four-ball friction pair is used to test the antiwear property of lubricating oil, meeting the requirements of SH/T 0189-1992 “Method for Determining Antiwear Property of Lubricating Oil (Four-ball Machine Method)”, and it has been widely applied to the development of antiwear hydraulic oil products.

2. This machine is widely applied to various fields of technologies of tribology, petrochemical, machinery, energy, metallurgy, aerospace, various junior colleges and research institutes (institutions).

Standerde of use

The wear resistance of SH/T0189-92 lubricating oil determination (four ball method)

The wear resistance of SH/T0204-92 grease determination (four ball method)

Method for the determination of the friction coefficient of SH/T0762-2005 lubricating oil (four ball method)

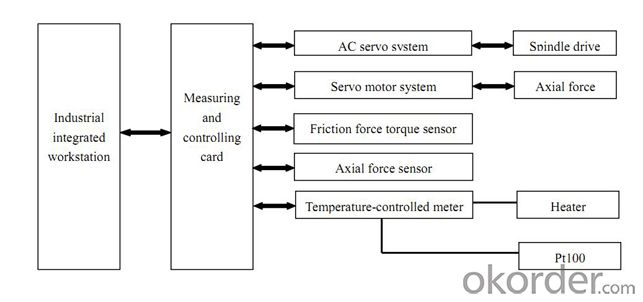

Schematic Diagram of Configuration of Microcomputer Controlled Vertical Universal Friction and Abrasion Testing Machine

Main technical performance indicators

1. maximum testing force:1kN

2. Test force working range: Maximum test force of 1%-100%

3. The relative error of the test force indication value is not greater than:±1%,

The indication error below 200N is not greater than:±2N

4. When the test force is long, the relative error of the indication value is not more than:±1%FN

5. Measuring the maximum friction torque:2.5N.m

6. The relative error of the friction torque indication is not more than:±2%

7. friction load sensor: 50N

8. The friction arm range: 50mm

9. Spindle continuously variable transmission system:1r/mi~2000r/min

100 r/min above the spindle speed error is no more than: ±5 r/min

100 r/min the following main shaft speed error is not more than: ±1 r/min

10. Special deceleration system:0.05 r/min~20r/min

11. Test medium: oil, water, mud, abrasives, and so on

12. heater operating range: room temperature-200(260℃)

13. temperature control accuracy: ±2℃

14. Test machine spindle taper: 1:7

15. Test machine spindle and the next set of distance:≥75mm

16. Test machine spindle control:manual control,time control,speed cycle control,friction torque control

17. Test machine time display and control range:0s~9999min

18. Test machine speed cycle display and control range:0~9999999

19. Spindle motor rated power:1kW

20. Test machine of the shape size (length * width * height):860mm×740mm×1560mm

21. Test machine net weight:About 400kg