Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1000 roll

Supply Capability:100000 roll/month

Quick Details

Material:Nylon

Type:Co-extruded film

Usage:Vacuum Infusion

Feature:High-Temp resistant

Hardness:Soft

Processing Type:Multiple Extrusion

Transparency:Transparent

Place of Origin:Zhejiang, China

Product name:Vacuum bagging film

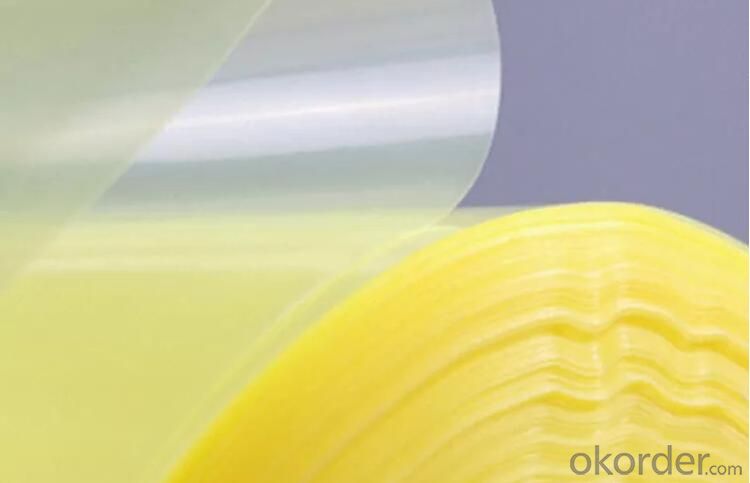

Color:Transaprent/Yellow

Thickness:50/65/75um

Width:4m,6m,8m

Temp resistance:120℃

Supply Ability

Supply Ability

1000000 Square Meter/Square Meters per Month

Packaging & Delivery

Packaging Details

paper tube inside, plastic wrap outside and finally packed in pallet.

Lead Time:

Quantity(square meters) | 1 - 1000 | >1000 |

Est. Time(days) | 7 | To be negotiated |

Vacuum bagging film is a five co-extruded film vacuum-type with charactors of soft and pliable. It has the characteristics of high strength, good air-tightness, soft texture, uniformity thickness, high breaking elongation rate. Excellent ductility makes it meet the requirements of various shapes easily, and its high temperature properties make it easy to apply to processes of "vacuum infusion resin" and "wet vacuum". It is widely used for producing yachts, wind-power blades, cabin cover, car surrounded, bonnet, helmets and other components with high strength and light weight.

With the continuous improvement of low viscosity, low exotherm, and thermosetting resin system on manufacturing technology, the core material with good diversion performance, the vacuum resin infusion processing is gradually widely used in composite materials production, so as to achieve the desire of improving FRP product quality, maintaining the integrity of its structure, reducing weight, and reducing overall costs becomes possible. This process has been successfully applied to large wind blades and nacelle covers, train head covers, safety helmets, yachts, ship, sports equipment, etc. Vacuum Infusion processing is a new type of low-cost composite material large-scale forming technology, which eliminates the air of fiber reinforcement materials under vacuum, the use of auxiliary materials can help exhaust excess air, control the resin flow well, achieve impregnation to the fibers and fabrics, so that it can be cured successfully and perfectly.