Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:100 pc

Supply Capability:1000 pc/month

Normal pressure or rating | Class 150-Class 2500,JIS I0K - 20K,PN 10 - PN 420 | |||

Normal diameter or bore | NPS 1/2-40,DN6-1000 | |||

Applicable temperature | -196℃-540℃ | |||

Operation type | Manual,worm gear,pneumatic,electric | |||

Standards and specification

| Design&manufacture

| API6D.API608.ASMEBI6.34,ISO5211,ANSI/AWWAC507,BFCI70-2.MSSSP-72,BS5351,B56364,NACE MR0175

| Connection ends

| ASMEBI6.5,ASMEB16.47.API 605,MSS SP-44,ISO 7005-1,JISB2238,BS12627,ASMEBI6.25,ASMEB16.11,BS 12760 |

Face to face dimension | ASMEB16.10,ISO 5752,BS 558, BS12982

| Testing &inspection | API598,API6D,API607,API6FA,BS6755.BS12569,MSS SP-82,MSS SP-6I | |

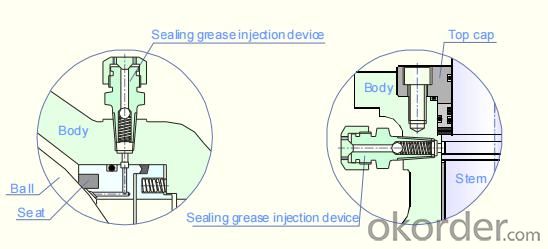

Urgent grease injection device

According to customers requirement, the trunnion ball valves made by our company are provided with devices for urgent grease injection, which are on both the stem and seat for the trunnion ball valves of DN 150mm(NPS6), and in the body cavity for the valve of DN 125mm. When the O ring of stem or the body seat ring is damaged due to accident the medium leakage between body and stem can be prevented by injecting the sealing grease through the device

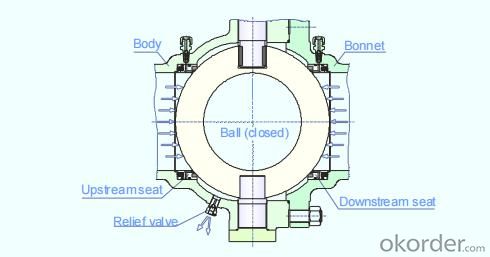

Double-block and bleed functions

In general, trunnion ball valve features the front ball sealing design structure. Each seat of the ball valve can separately cut off the medium at both inlet and outlet of the valve to realize double-block functions. When the ball valve is closed, body cavity and two of the body ends can be blocked with each other even if both the inlet and outlet are under pressure, when the medium left in the body cavity might be bled through the relief valve

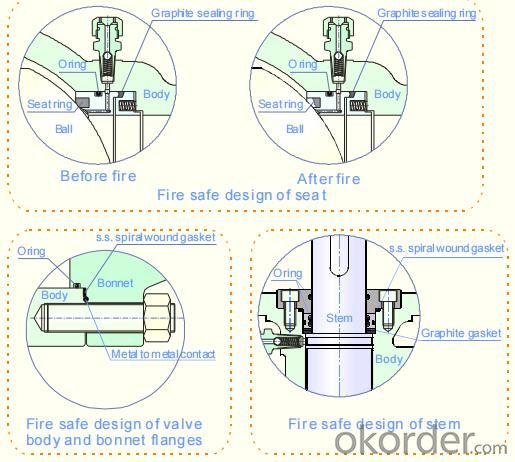

Fire safe design

With the valve heated in a fire application, the non-metal material parts such as seat sealing ring of PTFE, O ring for the stem, and sealing gasket for body and bonnet, might be damaged due to high temperature. Special design of auxiliary metal to metal or the graphite seal is provited for the trunnion ball valve to effectively prevent both internal and external leakage of the valve. As required by customers fire safe design for the trunnion ball valve meets the requirement of API 607, API 6fa, BS 6755 and JB/T 6899

Self-relief in the body cavity

As the liquid medium left in the body cavity gasifies due to increased temperature, the pressure in the body cavity becomes abnormally higher, when the medium itself in the cavity would propel the seat and self-relieves the pressure to ensure the safety of valve

Trunnion ball valve with the Bi-sealing design structure, i.e. seat se aling in front of the ball and seat sealing behind the ball

According to some special working conditions and customers requirement, We has provided the trunnion ball valve with the Bi-sealing design structure, i.e. seat sealing in front of the ball and seat sealing behind the ball thus the reliable sealing of the valve is ensured because the valve can perform normally even if one of the effective sealing designs becomes lost due to the abnormal condition

Regarding the seat in front of the ball, the piston effect formed by the area difference between D1 and D2, plus the pre-tightened force of a spring would cause the seat in front of the ball by the pressure difference of the medium before and after the valve to touch the ball closely to form the tightness, of which the sealing force will become bigger as the pressure difference gets hig her

Regarding the seat after the ball, the piston effect formed by the area difference between D2 and D3, plus the pre-tightened force of a spring would cause the seat behind the ball to touch the ball closely to form the tightness, of which the sealing force will become bigger as the pressure difference gets higher

Blow-out proof stem

Blow-out proof structure is provited with for the stem which is positioned by the up-end cap and screw, being guaranteed not to be blown-out by the medium even if at abnormal rise n pressure in the cavity

Anti-static design

The ball of the trunnion ball valve gets close contact with each othe th rough the trunnion, adjusting cushion, and down-end cap, the passage of static electricity thus forms together with the valve, which may le ad the static electricity caused by sparks generated by friction between the ball and seat during on and off perform ance to the ground to prevent the possible risk of fire or explosion.