Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:1000000 unit/month

Introduction

The system is mainly used for super small flow quantitative feeding control of different industrial additives and industrial small kiln fuels under normal temperature. It combines the quantitative feeding and air locking; in addition, it can feed several devices at the same time.

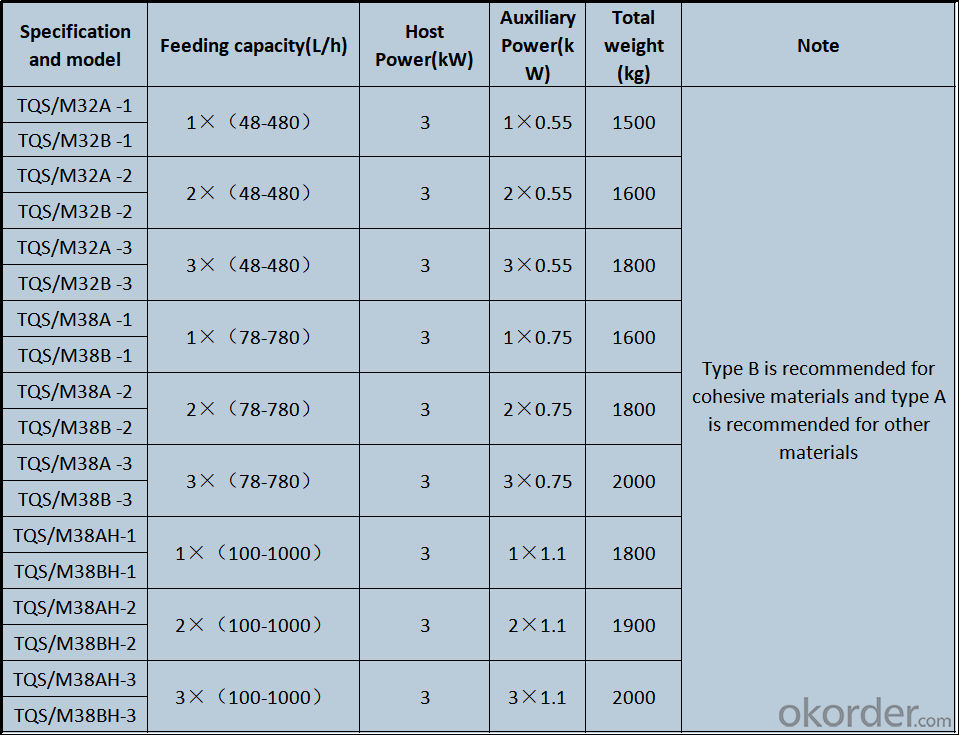

Technical indexes

Applicable material: powdery material (fineness: 10% on 0.08mm sieve)

Moisture: <2%

Feeding capacity: ≤1500L/h

Metering accuracy: ≤±1.0%

Control accuracy: ≤±1.0%

Characteristics

1. The system is of flexible disposition, which can save space and large amount of storage & civil cost. According to the actual process situation, the system can feed one device or several devices at the same time.

2. The system is of fully-sealed design, without any dust pollution, which is especially appropriate for quantitative feeding of absorbent material.

3. The system is of multi-layer construction, which can realize prehomogenization and uniform material pre-feeding.

4. The gear type feeding rotor with special design can effectively ensure the feeding accuracy.

5. The rotary part inside the system is of integral paged structure, so the single feeding structure is small.

6. The feeders of different stages in the system are controlled individually, without any influence between each other.

Company Introduction

Hefei GoodTimes Automation Co., Ltd. is a technique oriented state-level high-tech enterprise, transformed from Hefei Jinshan Science and Technology Industrial Company organized on the basis of automation institute of Hefei Cement Research & Design Institute Corporation Ltd. under of CNBM.It was awarded the Anhui Industrial Design Center, Hefei Enterprise Technology Center, Hefei Brand demonstration Enterprise, Hefei Engineering Technology Research Center. The core team is composed of the automation laboratory of construction institute. It is a scientifific and technological enterprise with a long history and strong technical strength, which integrates scientifific research and development, equipment manufacturing, engineering settings, and technical service.The company has established a perfect quality assurance system, which has passed the authentication of ISO9001 quality management system certifification,ISO14001environment management system certifification,OHSAS18001 occupational health & safety management system certifification, level 3 work safety standardization and Certifificate for China Compulsory product certifification.It is engaged and specialized in the development of the whole series of material measurement, process control, factory power distribution and electric control, monitoring and control devices for cement production as well as their manufacturing and services. The company has inherited innovative development experience from the core team for more than 60 years. It is staffed with a professional team with fifirm grasp of the latest technology and rich practical experience. In product development, production and services, it adheres to the business concept of “Customer-centered, innovation-driven, aiming at the win-win”. The company will continue to make customers feel “carefree, assured and content"