Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:20 m²

Supply Capability:2000 m²/month

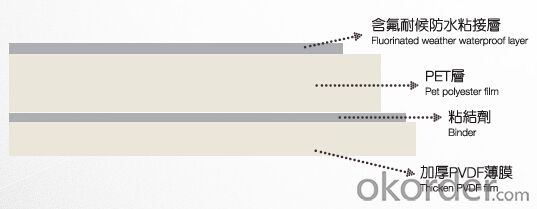

TPt300 BackSheet for Solar Panel is a new generation of backsheet for solar panel, as an important component material of solar panel, new technology helps the backsheet have better performance and wider use. There is 4 layer`s structure of this series: Thicken PVDF film, binder pet polyester film, Fluorinated weather waterproof layer.

2. Main Features of TPt300 BackSheet for Solar Panel

With thicken PVDF film, we have better weathering, water blocking performance compare to PVF film(Tedlar)

More reliable inner film, easier for reworking.

Simple structure makes our BackSheet more reliable, more cost effectiveness.

3. TPt300 BackSheet for Solar Panel Images

4. TPt300 BackSheet for Solar Panel Specification

| Layers of material

| Element | Thickness | Properties |

Weather proof layer | Thicken PVDF film | 43 μm | Weathering & |

Binder | Imported polyester adhesive | 10 μm | Adhesive property |

Thicken PVDF film | White PET | 250 μm | Insulating property \ Mechanical support |

Fluoride weather-water-proof layer | FEVE compound | 3 μm | Weather proof \ water proof \ strong bonding to EVA |

Testing Item | Testing method | Unit | Specification value

|

Thickness | GB/T 13541-92 | μm | 305±10 |

Tensile strength(MD/TD) | ASTM D-882 | N/cm | MD ≥300 TD ≥300 |

Elongation at break(MD/TD) | ASTM D-882 | % | MD ≥100TD ≥80

|

Heat shrinkage rate (MD/TD) | GB/T 13541-92 |

% | MD≤1 TD≤1 |

PVDF/PET peel strength | 180° peel | N/cm | MD ≥5 TD ≥5 |

T-layer cross-cut testing |

GB/T9286-1998 |

level |

0(no drop) |

T-layer cross-cut test after 24 hrs boiling | |||

Peel strength with EVA film | 180° peel | N/cm | ≥40 |

Breakdown voltage | ASTM D-149 | KV | ≥17 |

Partial Discharge | IEC 60664-1 | VDC | ≥1000 |

Moisture vapor transmission rate (MVTR) | 38℃,90%RH |

g/day.m2 |

≤2 |

5. FAQ

1. How to choose backsheet for solar panel?

It’s not easy question, but the first but most important thing is that the life period of the solar panel depends on the material quality of the backsheet.

2. If there is some scratches on the backsheet, how to deal with the solar panel?

Firstly, the scratch will destroy the waterproofness of the solar panel through the backsheet, which will finally have bad influence on the performance of the panel,; then the scratches on the backsheet should be regarded as defective and you should contact with the supplier or manufacturer to change it as soon as possible.

3. What is the color that backsheet should be?

Absolutely is white. As time goes by, the corrosion of the backsheet makes the white color into yellow. So make sure when you get the new solar panel the backsheet is in appropriate state.