Loading Port:China main port

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:30 unit/month

Structure of Tower Crane TC6024 Description

Feature: Tower Crane

Condition: New

Application: Construction

Max.Lifting Load: 10T

Max Tip Load:2.4T

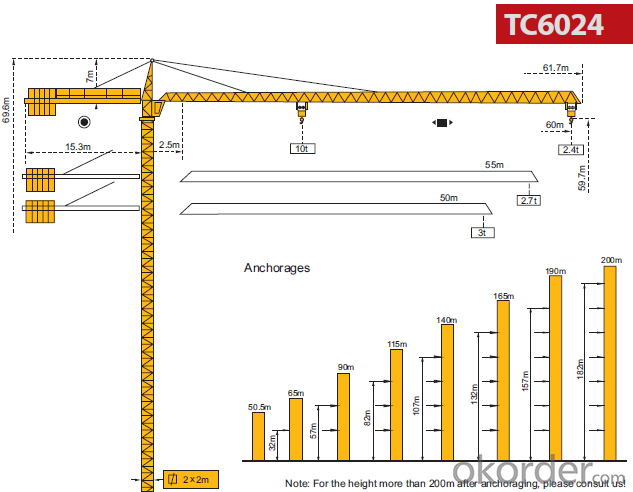

Independent Height:50.5M

Max Lifting Height: 200M

Span: 60m

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: TC6024

Characteristic of Tower Crane TC6024

1) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

2) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter, weight limiter, circumgyrating limiter, etc.

3)The machine has scientific layout and beautiful appearance. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operator.

4) Max. working range 60m, tip lifting weight 2.4T and Max. lifting weight 10T.

5) Slewing mechanism and trolleying mechanism equipped with VFD technical control, stable and reliable,can provide stepless speed regulation.

6) Outstanding in working efficiency, operating speed and stability. Reduce future maintenance cost.

Tower Crane TC6024 Specifiction

Free standing height (m) | 50.5 | |||||||

Max height with attachment (m) | 200 | |||||||

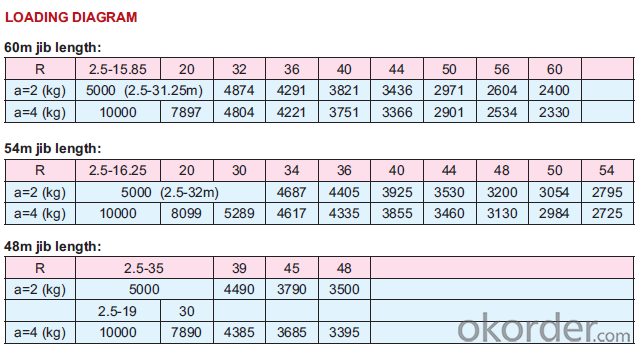

Working range can be adjusted(m) | 48、54、60 | |||||||

Min working range(m) | 2.5 | |||||||

Max lifting capacity(t) | 10 | |||||||

Tip load @ 60m(t) | 2.4 | |||||||

Hoist mechanism (VFD+PLC) | Falls | 2 | 4 | |||||

Lifting capacity(t) | 0-2.5 | 0-5 | 0-5 | 0-10 | ||||

Speed(m/min) | 0-80 | 0-40 | 0-40 | 0-20 | ||||

Motor | YZPBF250M1-6-45KW | |||||||

Trolleying mechanism (VFD+PLC) | Speed(m/min) | 0-56 | ||||||

Motor | YZPBE132S-4-5.5KW | |||||||

Slewing mechanism (VFD+PLC) | Speed(r/min) | 0-0.6 | ||||||

Motor | YTW112M-4-5.5KW×2 | |||||||

Climbing speed(m/min) | 0.5 | |||||||

Counterweight (t) | 48m jib | 54m jib | 60m jib | |||||

15.45 | 17.85 | 18.9 | ||||||

Mast section size(L×W×H)m | 2×2×3 | |||||||

Working temperature | -40-+60℃ | |||||||

Total power (KW) | 63 | |||||||

Power supply requirement (KVA) | 230KVA for generator | |||||||

Cable type ( within 35 meters from site power source to lower electric box of tower crane ) | 50mm2(3+2, 5 cores) | |||||||

Startup voltage & current | 380V×95%=361V 219A | |||||||

Rated working voltage & current | 380V 121A | |||||||

Images Tower Crane TC6024

FAQ of Tower Crane

Q: What is the principal to quote the right tower crane to the client?

A: First, we need to know clients’ requirements. Normally the following information should be clarified by the client: max lifting capacity, height (height under hook), tip load and jib length.

Second, we need to know what the foundation requirement from the client is. (Fixed/undercarriage/ undercarriage with traveling system), mast section type (panel/integrated), power supply source (voltage, ampere and frequency), the distance between the machine and power supply……

Third if there are special needs, we could suggest proposal according to clear data provided by the clients. End-user, as construction machinery buyer, knows the site situation well and should make decision, such as the machinery specification, type…….

Q: What about our tower crane's warranty?

A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients’ requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.