Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:26 m.t.

Supply Capability:35000 m.t./month

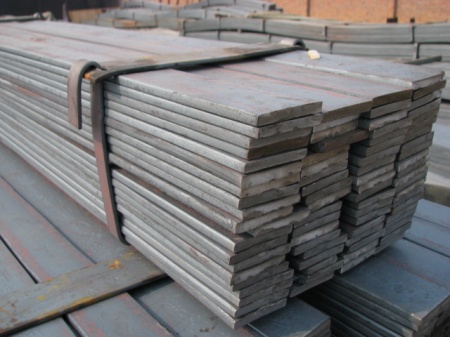

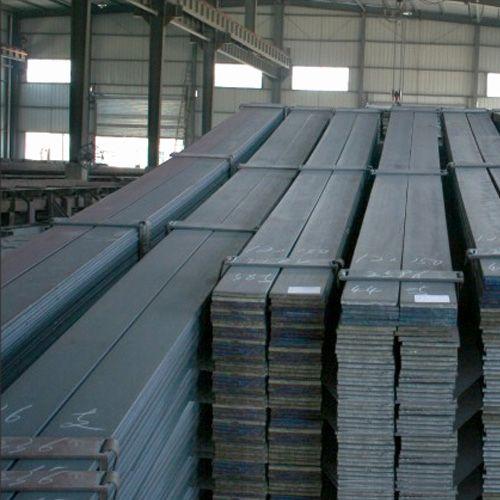

Tool Steel D6 Steel Plate,1.2436 Flat Bar, Forged D6 Steel Bars

Delivery stock within 7 days

ISO9001&BV factory

Flexible MOQ

Tool Steel D6 Steel Plate, Forging Flat Steel 1.2436 Flat Bar, Forged Steel D6 Steel Bars

JC Cold work tool steel products

Specifications

Tool Steel D6 Steel Plate, Forging Flat Steel 1.2436 Flat Bar, Forged Steel D6 Steel Bars

Prompt delivery stock within 7days

MTC DIN10204 3.1/3.2

ISO9001 certified

Flexible MOQ

Equivalent grades

| GB | DIN | AISI |

| Cr12W | 1.2436 | D6 |

Chemical Composition

| C | Si | Mn | Cr | P | S | W |

| 2.06-2.36 | 0.10-0.40 | 0.15-0.45 | 11.0-12.0 | ≤0.03 | ≤0.03 | 0.60-0.80 |

Available sizes

| AISI D6 round steel bar dia 60-800mm | |||||||||

| ASI D6 flat steel bar 25-400mm*200-800mm |

Surface condition

| Black surface/ Grinded/ Machined |

Hardness

| Annealed HB255MAX |

Characteristics

Tool Steel D6/ 1.2436 has: Dry hardening,have upper hot intensity and rigidity, under middle pemperature; |

Applications

| Forged Tool Steel D6, Rolled Tool Steel D6 is used in cutting and drawing tools of high wear resistance, rolls with high dimensional stability, deep drawing tools, tools of wire, bar and tube production, cold shear blades for thin sheets |

Heat treatment

| Annealing temperature: 860-880°C Constant temperature cooling Annealing hardness: ≤255 HB Quenching temperature: 950-1000°C Cooling in air or in oil if large parts. Tempering hardness: ≥60HRC |

16:40:34