Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 m²

Supply Capability:10000000 m²/month

1. Structure of Timber Beam Wall Formwork Description

Timber beam wall formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost. The system is convenient for construction and it is easy to control the quality. The system has two parts, formwork and pull-push props. The formwork is made of plywood, timber beam and steel waling. Pull-push props can be designed according to the project or simply select the standard props. Tie-yoke and tie-rod are used to reinforce the corner.

2. Main Features of Timber beam wall formworks

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

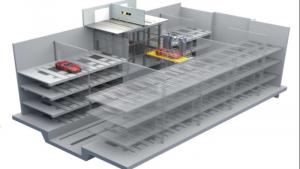

3. Timber beam wall formwork Images

4. Timber Beam Wall Formwork Specifications

Timber beam column formwork is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.FAQ of Timber Beam Wall Formwork

1) What can we do for you?

.We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

H20 timber beams SPECIFICATION:

1)Materail:New Zealand Radiate Pine

2)Flange: 80*40mm(LVL Structure)

3)Web: 27mm (Plywood or LVB Structure)

4)Weight/: 5.00kg-5.20kg/meter

5)Length avaible:Max 12meter

6)Quality: SGS test report according to EN13377:2002

7)Surface finishing: waterproof yellow painting or other color as the customers request

8)Package:Pallets on the bottom,and Steel band for strength

9)GLUE:WBP/MUF

10)Price advantage: 20-30% cheaper than Austria based on same quality

Product Name | |

Height | 200mm |

Flange | Wide*Thickness=80mm*40mm |

Spruce, Pine, a mixture of wood species permitted | |

Web | Thickness:27-30mm |

3-plywood or plywood | |

Surface Protection | The complete beam is waterproofed using a water-repellent color glaze |

Weight | 4.6-5.2kg |

Standard Lengths | 2.45m,2.65m,2.9m,3.3m,3.6m,3.9m,4.5m,4.9m,5.9m, (Max.length:6.00m) |

Shear Force | q=11KN |

Permissible Bending Moment | m=5.0KN*M |

Package | Customized Package,or In Bulk |

Used for | Slab Formwork System,Vertical Formwork(Wall,Column,Hydraulic Climbing etc.), Adjustable Arced Formwork etc |

H20 Beam/H16 Beam and Film Faced Plywood

H20 beams advantage:

1.With low weight, high rigidity and water proof, timber beam H20 is one of the most important components in the formwork system all over the world. It can be repeated used for many times, which save much cost. 2. Timber beam can be widely used in slab formwork system, vertical formwork (wall, column, hydraulic climbing etc.), adjustable arced formwork etc. 3. Timber beam system is easy to operation and can be assembled in different size and shape of formwork within certain range. The max. pouring height can be over 10 meters. As the lower weight of the materials, the formwork is much lighter than steel formwork. 4. With high standard components, the formwork can be repeated used for many times. 5. The wing board is using dried pine with a percentage of moisture below 13%. The wing board is composed of many pcs of short pine by using special adhesive to avoid the internal shear force. The web board is using plywood. 6. The surface of the timber beam is water proof, acid proof and alkali proof.