Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:4 set/month

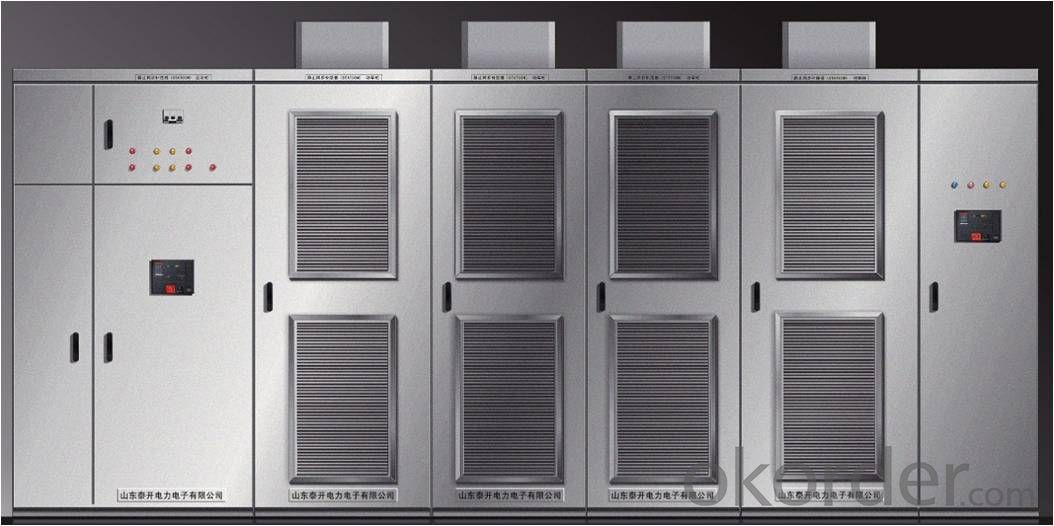

Thyrister Control Reactor Static Var Compensator

Static Var Compensator is a set of electrical devices for providing fast-acting reactive power on high-voltage electricity transmission networks. SVCs are part of the Flexible AC transmission system device family, regulating voltage, power factor, harmonics and stabilizing the system. Unlike a synchronous condenser which is a rotating electrical machine, a static Var compensator has no significant moving parts (other than internal switchgear). Prior to the invention of the SVC, power factor compensation was the preserve of large rotating machines such as synchronous condensers or switched capacitor banks.

The SVC is an automated impedance matching device, designed to bring the system closer to unity power factor. SVCs are used in two main situations:

·Connected to the power system, to regulate the transmission voltage ("Transmission SVC")

·Connected near large industrial loads, to improve power quality ("Industrial SVC")

In transmission applications, the SVC is used to regulate the grid voltage. If the power system's reactive load is capacitive (leading), the SVC will use thyristor controlled reactors to consume Vars from the system, lowering the system voltage. Under inductive (lagging) conditions, the capacitor banks are automatically switched in, thus providing a higher system voltage. By connecting the thyristor-controlled reactor, which is continuously variable, along with a capacitor bank step, the net result is continuously variable leading or lagging power.

In industrial applications, SVCs are typically placed near high and rapidly varying loads, such as arc furnaces, where they can smooth flicker voltage.

The main advantage of SVCs over simple mechanically switched compensation schemes is their near-instantaneous response to changes in the system voltage. For this reason they are often operated at close to their zero-point in order to maximise the reactive power correction they can rapidly provide when required.

They are, in general, cheaper, higher-capacity, faster and more reliable than dynamic compensation schemes such as synchronous condensers.However, static Var compensators are more expensive than mechanically switched capacitors, so many system operators use a combination of the two technologies (sometimes in the same installation), using the static Var compensator to provide support for fast changes and the mechanically switched capacitors to provide steady-state Vars.

Key Technologies of TAI KAI SVC:

·The control system adopts the fully digital controller based on DSP, with features of short response time and high accuracy. The response time of control system is less than 15ms, and the tracking response time of the whole device is less than 30 ms.

·Adopt modular design, adopt the same structure for the devices with different compensation capacity.

·Monitoring control system uses integrated workstation,provides good human-machine interface,large-screen LCD is used in site-workstation and far workstation.

·Thyristor valve uses bunching antiparallel pressure welding and can withstand the maximum overcurrent and overvoltage level of SVC device, and adopts high potential circuit board obtaining energy, which makes thyristor free of damage due to overvoltage impulse.

Rated voltage | 6kV/10kV/22kV/27.5kV/35kV |

Rated Frequency | 50Hz (±2%) |

Rated reactive output | Capable of continuous output that ranges from inductive rated reactive to capacitive rated reactive |

Connection mode | 3phase3wires Star connection |

Response Time | ≤15ms |

Active-power loss | ≤2% of rated power |

Overload capacity | Capable of continuous operation at 1.1 times overload |

Harmonic characteristics | When it only compensates reactive power output, THDU <3%, THDI <4%; harmonic="" suppression="" rate="" when="" wave="" harnessing="">85% |

Allowable unequalization degree of voltage | The permissible value of unbalance degree of connection-point system voltage shall not exceed 60% |

Operation indication | Touch screen, full-digitalized control |

Protection function | Power grid overvoltage, undervoltage, voltage imbalance; overload, inverter over/undervoltage, overcurrent , overtemperature; capable of automatic exiting from the power grid in case of a equipment failure |

Communication modes | Ethernet; capable of background-computer remote monitoring; reserved with RS485/232 interface |

Cooling system | Forced air cooling |

FAQ:

Q: What certifications do you get?

A: We have ISO9001/14001/18001, TUV, CCC, etc.

Q: Are OEM&ODM available?

A: Yes, we accept OEM and ODM.

Q: When to get the price?

A: We usually quote within 24 hours after getting your inquiry. If that is the tender project, our engineer will issue optimized design as per tender specification and all the documents will be submitted as per the time schedule regulated in the tender.

Q: Is sample available and free?

A: Sample is available, but sample should be paid in advance. The cost of sample will be refund after further order.

Q. How to pay?

A: T/T and L/C are acceptable, and T/T will be more appreciated.

(30% deposit before producing, 70% balance before loading by T/T. L/C should be at sight which issued by world first class Bank)

Q. What is the delivery time?

A: It depends on the order quantity and the season you place the order. Generally, one month after the receipt of the 1st payment.

Q. What about the Package?

A: Standard export package and we can make special designed for you if need.