Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:2 pc

Supply Capability:10000 pc/month

Ceramic Fiber Board for Fireplace 1260C

Product Description

General Information

offers a family of high temperature ceramic fiber board,which are produced through wet forming process of ceramic fiber and binders.ceramic fiber board is featured with high temperature stability,low thermal conductivity,even density,and excellent resistance against thermal shock and chemical attack.

Ceramic fiber board also resists oxidation and reduction. If they are wet by water,steam,or oil,physical and thermal properties are fully restored upon drying. Ceramic fiber board is used for a variety of high temperature applications, including refractory linings,backup insulation, baffles and muffles, heat shields, combustion chambers, flue insulation, and fire protection.

These ceramic fiber board are available in a variety of temperature ratings, densities,thickness, widths and lengths, and custom vacuum formed shapes. These materials can use in great variety of applications in high temperature insulation industries

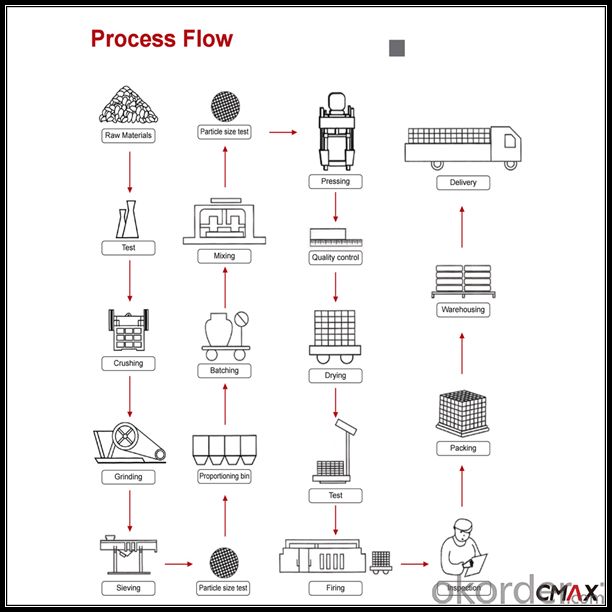

1. Ceramic Fiber Board was processed by the advanced production line, which was adopted the full automatic control and the continuous- processing method.

2. Ceramic Fiber Board have many typical characteristics, such as exact measurement,excellent toughness,excellent heat preservation and can be cut discretionally

3. The processing work is much advanced, which totally avoid the long production cycle and the low production capacity.

4. Ceramic Fiber Board is divided in different series by the temperature, can be widely used as the back lining of industrial furnace and the hot surface of the low temperature furnace. It is one of the guarantees of reaching the energy conservation and the high quality.

Characteristics

1.Low thermal conductivity, low heat capacity.

2.Excellent thermal stability and thermal shock resistance.

3.High strength and good toughness.

Features

1.High temperature ceramic fiber board

2.Good sound insulation

3.ISO9000,CE,REACH certified

4.The Ultra-thin size:3mm

Application

1. Industrial furnace wall lining, masonry insulation layer.

2.High-temperature furnace of the kiln liner, kiln cars, door baffles, kiln temperature dividers.

3. High-temperature, high temperature equipment, heat insulation, thermal insulation.

4. Aerospace, shipbuilding insulation, fire protection, sound insulation, insulation.

Characteristics

Non-brittle material, good elasticity;

Good sound insulation;

Accurate sizes and good flatness

Kiln construction: Hot surface refractories, heavy refractory back linings, expansion joints.

Light industry: Industrial and household boiler combustion chamber lining;

Petrochemical industry: as high-temperature furnace hot surface lining material;

Craft glass: As craft glass or other deep-processed and molded products mold;

CERAMIC FIBER BOARD ---STD

Classification Temperature (℃) | 1260 |

Working Temperature (℃ ) | 10 00 |

Color | White |

Bulk Density (kg/m3 ) | 240-300 |

Thermal Conductivity(W/m.k) | |

400℃ | 0.067 |

600 ℃ | 0.094 |

800 ℃ | 0.136 |

1000 ℃ | 0.152 |

1200 ℃ | 0.190 |

1300 ℃ | - |

Thermal Shrinkage 24hrs (%) | 1200℃ |

-3.3 | |

Chemical Composition (%) | |

Al2O3 | 45-47 |

Al2O3+ SiO2 | 97-98.5 |

Note: Technical Data are typical results from test pieces. This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

Ceramic Fiber Board Process Flow

Packaging & Shipping

Packaging Details: Wrapped by plastic bag and then put into carton box designed for export.

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research,development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection,supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Company Information

CNBM (China National Building Material) Group is the largest comprehesnsive building materials group in China that in intergrate scientific research,manufacturing and logistics into one entity.the largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields,CNBM is playing the leading role in the building industry in the country.

Why us?

♦ We are the only enterprise that supply all the ceramic fiber products for exportation

♦ We are always in a leading position in the ceramic fiber export industries After a decade of development,

♦ We have the 20,000 square meters factory area ,Sales volume increasing multiplies each year.

♦ we equipped with 23 ceramic fiber blanket production lines,4 ceramic fiber felt & board production lines,2 ceramic fiber

paper &ceramic fiber textile lines.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.If any question, please contact us freely.