Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:3000 kg/m³

Supply Capability:300000 kg/m³/month

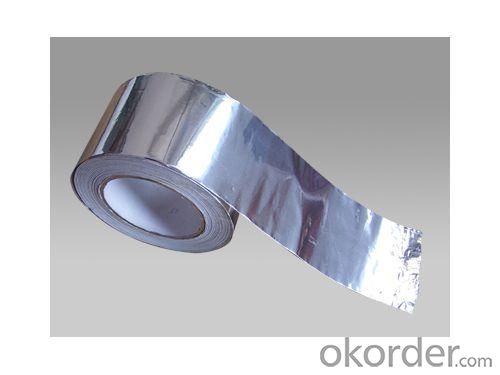

| Material: | Aluminium Foil | Use: | Masking | Adhesive Side: | Single Sided |

| Adhesive: | Rubber | Adhesive Type: | Pressure Sensitive | Feature: | Heat-Resistant |

| Design Printing: | Offer Printing | Place of Origin: | Jiangsu China (Mainland) | Brand Name: | T-S3001UL |

| Model Number: | CMAX | Thickness: | 16um | Using Temperature: | -20~+80℃ |

| Construction Temperature: | +4~+80℃ | Endurance Bonding Strength: | 1400min | Adhesion To The Aluminum Foil: | 18N/25mm |

| Adhesion To Stainless Steel: | 18N/25mm | Glue Flame Retardant: | 4 grade optional |

A high tensile strength aluminum foil backing, combined with a high performance flame-retardant synthetic rubber-resin adhesive.

Features:

16 um. soft aluminum foil,coated with high adhesive strength,high initial viscosity and high performance emulsion pressure sensitive adhesive, which provides high peel adhesion and quick sticking,strong holding power and high-grade fire rating.

Usage:

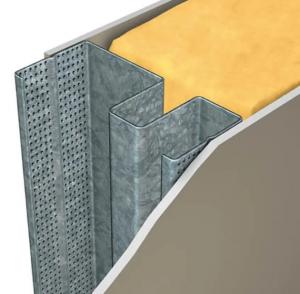

Designed for moisture sealing of glass wool board air duct and galvanized metal air duct system,Also suitable for sealing joints and interfaces foil veneer.

Specifications:

ITEM | UNIT | FIGURE | TEST METHOD |

Thickness | μ | 16 | PSTC-33 |

Glue Flame Retardant | grade | 4 grade optional | UL94 |

Adhesion To Stainless Steel | N/25mm | 18 | PSTC-1 |

Adhesion To The Aluminum Foil | N/25mm | 18 | PSTC-1 |

Endurance Bonding Strength | min | 2000 | PSTC-7 |

Construction Temperature | ℃ | +4 ~ +80 | |

Using Temperature | ℃ | -20 ~ +80 |

Remarks:

1. The above data are typical indicators, subject to alternation without prior notice.

2. The thickness of aluminum foil with a variety of optional.Tolerance: quantitative and thickness

of ± 10%; width of ± 3mm; length: small volume and long scroll of ± 0.3m, parent roll of ± 0.5%.

3.The product should be stored at room temperature, away from moisture and heat.

Shelf life: stored in the 21% and 50% relative humidity, valid for a period of six months since the

date of production.

4. Like the stick of all the pressure sensitive adhesive tape, the surface of pasted material must be

clean , free of grease and pollution. Otherwise, it will seriously reduce the adhesion of aluminum foil tape.

5. User should be in their own suitability tests before use, to verify whether the product is suitable for their particular purpose and process conditions.