Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:30 unit/month

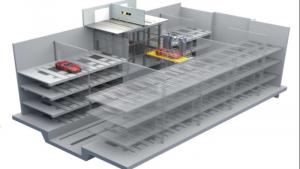

This model crane system is special designed for steel scrap charging for steel mill. Normally it is single beam or double beam crane hooked with magnet system ,or grab system, lifting and transferring steel scrap into scrap basket or directly to the furnace .This is a most high working duty heavy type crane system.

These extra heavy duty cranes are EOT cranes which are used to feed scrap into the furnace. These cranes work in very extreme heat and dusty conditions and have to be specially designed to withstand these extreme conditions. In some steel plants, these cranes are also sometimes used to also transport Molten Metal and therefore have to be designed accordingly. Special types of Heat Shields, Panel e-rooms / Cabins with air conditioners and other features are provided to withstand the very high temperatures. Special Drives, crane Controls and Automation features are used to provide exact accurate positioning of the crane to help the driver transport and charge the scrap into the furnace. Henan Mine Crane Co., Ltd continuously strives to provide High Speed, Continuous Operation CRANES with the minimum down-time required for maintenance of the cranes. Over many years of experience of Designing and Manufacturing Customized cranes for STEEL PLANTS.

Configuration:

Because of a higher risk level, special safety features are designed for the cranes that transport scrap metal.

The main hoist mechanism includes four independent rope reevings, double service brakes on primary shafts, and backup brake acting on the rope drum.

Rope equalizer beams are provided with a dampening unit to slow down equalizer beam tilting in case of wire rope failure.

An upper emergency stop limit switch is also used in the main hoist.

In addition to this overload protection, the 'emergency stop' system bypassed from PLC, derailment supports, main hoist overspeed supervision, and end limit switches are automatically standard features of the equipment.

Features:

Simple and reliable assembly

The under running overhead crane construction kit enables you to design almost any overhead suspension crane or monorail system. The track sections measuring up to eight metres in length are simply and reliably connected. They can be assembled quickly and precisely by hand as a "do-it-yourself" kit.

Cost-effective equipment

The suspension cranes can be simply suspended from the building roof or superstructure. Additional supports for the crane runway are not necessary. Even partial areas of a workshop may be easily fitted with suspension cranes at low cost.

Safe and reliable handling

The under tunning overhead travelling cranes can be easily moved thanks to their low deadweight and smooth-running trolleys. They ensure that heavy and awkward workpieces can also be handled safely and reliably.

Technical Data:

Lifting Capacity | T | 125/32 | 140/32 | 160/32 | 180/50 | 200/50 | 225/65 | 240/80 | 280/80 | 320/80 | |

Span | m | 19 | 19 | 27 | 28.5 | 28 | 27 | 22 | 22 | 24.5 | |

Speed | Main Hook | m/min | 7.8 | 9.8 | 7.5 | 6 | 11 | 7 | 12 | 7.5 | 7.6 |

Aux. Hook | 9.7 | 12 | 10 | 10 | 11 | 9.6 | 10 | 10 | 9.7 | ||

Main Trolley | 36 | 43.5 | 40 | 41 | 41 | 35 | 40 | 29 | 38 | ||

Aux. Trolley | 37.5 | 43.5 | 38 | 38 | 39.5 | 38 | 40 | 39 | 39 | ||

Traveling of Crane | 73 | 84 | 80 | 78 | 84 | 80 | 80 | 58 | 76 | ||

Max wheel pressure | Kn | 505 | 535 | 485 | 525 | 530 | 550 | 545 | 735 | 750 | |

Steel track recommended | QU120 | ||||||||||

Operational Model | Cabin; remote control | ||||||||||

Working Duty | A7-A8 | ||||||||||

Power Supply | Three-phase A.C. 380V, 50Hz or as your requirement | ||||||||||