Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

Steel cord conveyor belts

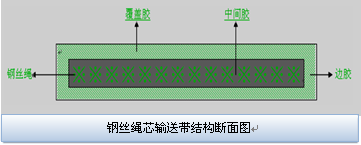

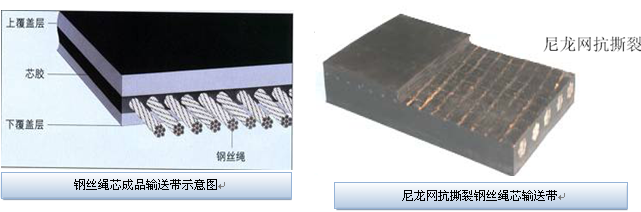

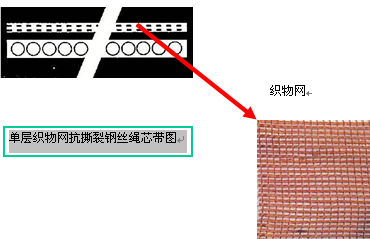

Steel cord conveyor belt is composed of single wire rope of the same diameter arranged according to certain spacing, twisting around and white, up and down repeatedly in different properties of the plastic core, plastic cover, after vulcanization. If you have special need, you can add transverse laceration resistant fabric mesh, wire mesh or buried coil, prevent tape horizontal tear or covered with special performance of rubber cover, and then made into different performance of steel cord conveyor belt.

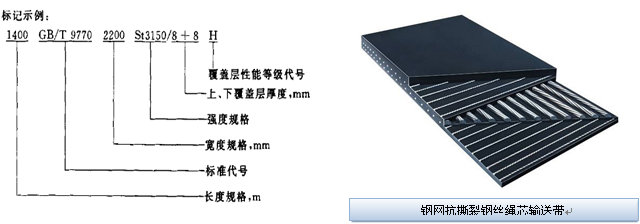

Product schematic diagram

Product presentation

Features & Benefits

1.Zinc Galvanized Open Type Steel Cord

Design and choose the best high strength galvanized steel wire rope, assurance and core glue good bonding strength. Aneng selects its cord construction to provid the best specification for a particular application, which is made up of multiple strands of wire, conducive to infiltration of the rubber,, important protective layer formed corrosion resistance, also can get higher coupling efficiency.

2.High Tension Capabilities

Shandong Aneng has made the highest level of domestic steel cord conveyor belt ST7500 steel cord conveyor belt.the belts handle the most demanding applications and design the strongest belt to meet the growing demand for long overland systems.

3.Limited Take –up Travel

Shandong Aneng belts elongate a maximum of 0.25%at a rated tension. This allows lower cost take-up system on many applications, and makes Shandong Aneng the preferred choice for long overland and short stacker/reclaiming systems. Where minimum elongation in critical.

4.Long Splice life

Over proven splicing methods, validated dynamic splice tester, rest in dynamic splice efficiencies in excess of 50% rating defined in DIN 22131 Part 3.With proper technique, splices on Shandong Aneng belts should last the life of the belt.

5.High Impact Resistance

Advanced cover compounds and tie guns superior adhesion combine to provide the good impact. tear and rip resistance your applications demand.

6.Lower Cost-per-Ton

Fewer conveyor and splices, shorter take-up, and reduced belt inventory. Longer belt ,longer splice life, and reduced downtime. it all adds up to the lower cost-per-ton of material conveyed ,which can make a major improvement in your bottom line.

Raw material specifications

Bid on this lot of conveyor belt, we will select material, to ensure product quality and service life.

1.Raw rubber:

Natural rubber selects the dong Thai poetry and Malaysia production of high quality rubber, styrene-butadiene rubber choose China national petroleum co., LTD., or Japan co., LTD production of quality products, butadiene-acrylonitrile rubber choose Japan co., LTD production of quality products.

2.The paste resin:

Contrast through the use of all kinds of paste resin, we adopt comprehensive physical performance is good, process stability of PSM 31 paste resin, ensure good soak and physical performance, so as to improve the service life of the product.

3.Reinforcing agent:

Use Cabot or it is Mr Black high wear-resisting and CSL production, to ensure the high strength and high wear resistance.

4.Adhesive:

With German degussa, or jiangsu national products, improve the adhesion performance between the paste and fiber, ensuring excellent static and dynamic fatigue adhesive performance, and improve the high life of the product.

5.Vulcanization accelerator:

Using times sulfonamide classes after effect of vulcanization accelerator, to ensure efficient vulcanization rubber speed and process stability, and excellent physical properties.

6.Stabilizer:

By tuv chemical production of wax and jiangsu sinorgchem group production efficient antiager 4020 and 4010 na, prevent rubber produced in ultraviolet radiation and ozone environment over a long period of ageing or cracked, raised the cover the use of the term, then improve the product's service life.

7.Dacron filament:

Woven belt core used in nylon yarn is used in the present domestic most of henan shenma group of nylon 66 production products, with features of high strength, large elongation and good dimensional stability, can improve the product into the slot. Polyester polyester yarn is shandong anneng Japan imported equipment the Goodyear proprietary technology, the optimal level of products, stable performance and reliable quality.

8.Woven belt core:

YouGen cored by UK WenErXun and Germany company production of heavy belt core knitting machine, with break automatic stop device, a high degree of automation. Advanced weaving belt core structure, tension is uniform. Don't wandering in use process, stable running.

9.Flame retardants:

From domestic production of hunan province and Qingdao best efficient flame retardant, in order to make sure the sizing performance of flame retardant and smoke suppression performance.

10.Steel cord:

Adopted at present of the world's most advanced hot galvanizing production process of open type steel wire rope. Between the wire rope because of stocks and shares with special structure, make the rubber can penetrate the steel wire rope, make the whole of the rubber and steel wire rope to form complete dense, sticky tape tightness is good. Adhesive tape in use, even if the surface of the cover rubber were broken or after corrosion, air, acid and alkali aqueous solution or humid air can enter the steel wire rope, thereby avoiding the spread out the steel wire rope corrosion fracture cause destruction of steel wire rope, thus extending the service life of the adhesive tape.

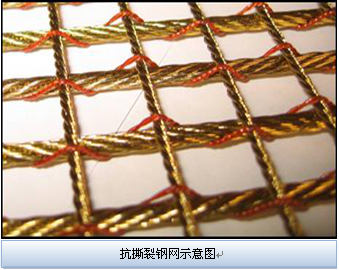

11.Steel breaker:

Steel cord conveyor belt is suitable for long distance, high speed, large capacity transmission block material, its advantage is unmatched by other laceration resistant fabric core conveyor belt, add tearing wire mesh product structure compared with the ordinary steel wire rope belt, has the following advantages:

A.Tensile steel net lateral high copper coated high elongation steel wire, and once the tape tearing, cumulative in several root tensile force.

B.After add tensile steel net, covered in glue and glue, glue and the longitudinal middle rope form network, greatly improve the shock resistance of the tape, puncture resistance, resistance to penetration.

C.Can prevent the foreign body through; This mesh of wire rope, open structure, with rubber adhesive performance is good.

12.Rip detection steel cord

In normal structural steel cord conveyor belt cover between rubber and rubber (or under the cover between the rubber and rubber), add a layer or two layers of tearing resistance network, prevent a foreign body into the body torn or belt.

Production equipment introduction and technical specifications

1.Production equipments

Company owns China's largest conveyor belt industry automatic mixing center, more than 20 production lines, the main equipment are imported from abroad. Including steel cord conveyor belt production line more than 10, 2010, the introduction of Germany simba bair kangpu company (Siempelkamp) of the world's largest specification for 3.45 m production line, and another 2.7 m x 18.5 m x 10 x 10 m m, 2.4 m, 2.2 m x 10 m more efficient intelligent plate vulcanizing machine, such as supporting and attached in a range of steel cord conveyor belt auxiliary system; In 2006 the introduction of Germany, toefl (BerSTorff) company AUMA20 x 2000 drum vulcanizing machine, can achieve continuous vulcanization maintaining a constant temperature and pressure; The overall equipment level in the world's most high-end industry.

2.Advanced production equipment is introduced

A.Mixer - Rubber mixing tap "product quality"

My company has a fully automatic large mixer machine 6 units, is currently the world's most advanced models, its various technical indicators have reached international advanced level of similar products. Machine design is reasonable, advanced structure, high manufacturing quality, use and reliable, long service life. Applicable to all kinds of rubber and rubber blending the plastication of required materials such as, mixing and refined. Characteristics are as follows:

a)Parts in contact with the rubber are water circulation cooling, cooling the area is large, and is equipped with temperature control water temperature control system, choose the appropriate water temperature, can effectively guarantee the quality of all kinds of rubber.

b)Control system adopts PLC and has manual and automatic functions, switch is convenient, can realize control of temperature and time, energy, and have perfect signal testing, feedback and security protection, a more effective control of rubber mixing quality, shorten the auxiliary time.

c)Computer network, automatic control parts to realize the automation, the whole process of rubber mixing improves the mixing density rubber and rubber mixing evenly, fundamentally guarantee the overall quality of the rubber.

B.Calender - To ensure the quality of products "key link"(shown on the right)

Film calender are used out currently the nation's largest and highest degree of automation of four-roll s-shaped XYD - 4 s2500 calender, maximum width 2500 mm, accuracy of + / - 0.05 mm, and an automatic compound on a rolling machine, rolling film thickness uniformity, smooth surface density, composite film thickness uniformity, a compound rubber and middle rubber rolling molding compound, reducing the cover rubber and middle rubber impurities mixed with; Bonding performance between layer and layer, reducing the sub intervals or blister delaminating defect; Spray cooling roll cooling device, make the film cooling after rolling composite effect is good, temperature uniformity, can make the film fully cooled to below 40 ℃, film deposit is safer, cooling molding operation more convenient, and can ensure that the quality of the preform.