Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:1000 m.t./month

Our company uses high-temperature flame melting method to produce spherical quartz powder, which has superior properties such as smooth surface, large specific surface area, high hardness, and stable chemical properties. The spherical quartz powder can be used in the industries below:

Epoxy Molding Compound(EMC): It can be used as filling material in the EMC to reduce thermal expansion and increase the intensity, thermal conductivity, corossion resistance of component and to save large quantity of resin.

Copper Clad Laminate(CCL): To increase the intensity and thermal conductivity of product so as to decrease production cost. Paiting and ink: To crease the absoption of ultraviolet and reflection of infrared ray so as to improve the aging property the color of paintings and inks. It could also used as deluster because of its property of anti-sedimentation.

Paiting and ink: To crease the absoption of ultraviolet and reflection of infrared ray so as to improve the aging property the

color of paintings and inks. It could also used as delusterbecause of its property of anti-sedimentation.

Cosmetics: our product can be applied to lipsticks, compact and foundation creamdue to its good dispersity and solubility in oil and water.

Ceramic composites: with good dielectric properties, low thermal expansion coefficient and good electrical insulation, they can be used for precision ceramics electronic ceramics, aerospace ceramics, honeycomb ceramics and special refractories.

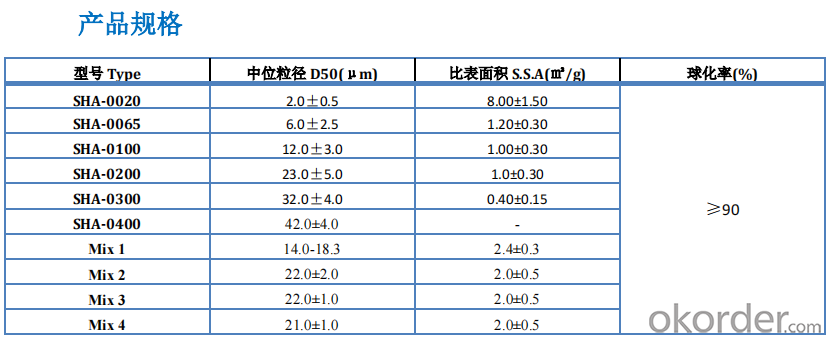

Features:1.high spheroidization rate: ≥95%; 2. good sphericity: ≥90;

3. High purity: the putiry of raw material is high and the contamination is avoided during the production;

4. Particle size distribution: the particle size distribution is controlable due to the accurate seiving method and vertex cutting.

5. High fludity: the dispersity is good and filling rate is high because we optimized our recipe on the particle size by adopting the theory of high packing.