Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:1000 m.t./month

Choosing High purity calcination α Alumina raw material and specially extracted Pure process treatment, our Spherical Alumina has good sphericity, high thermal conductivity. Meanwhile, we can provide customers with personalized solutions. It can be used in the industries below:

Thermal conducting filler: Applied in thermal conducting silica gel, silicone grease, thermal phase change pad and MC plate as thermal conducting filler so as to improve the thermal performance of the product.

Thermal conducting pouring sealant: Applied in the packege of some electronic elements which have higher requirement on the heating diffusion.

Honeycomb ceramics and ceramic filters: Good for the formation and uniformity of pore.

Grinding and polishing agent: applied in the fields such as equipment manufacturing, ornaments processing,mobile car repair and maintenence. The spherical appearance makes the polishing surface more smooth with fewer scratch due to higher Mohs hardness.

Basic Feature: High Sphericity: By adopting the technology owned by ourselves, the sphericity is more than 92% and spheroidization rate is more than 90%.

High purity: By choosing the high purity raw material and treating the surface impurities with special purification process, the aluminium oxide content is no less than 98% and the content of ion on the surface is low.

High thermal conductivity: The thermal conductivity of αtype alumina is higher than 90%, due to its surface is compact and seamless.

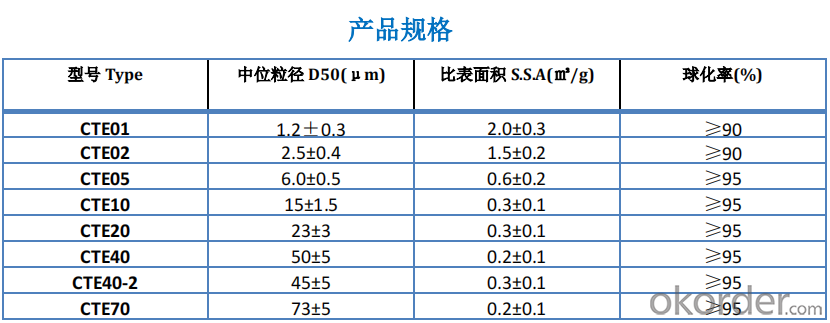

Particle size distribution:The precise control of product particle size distribution,can produce the narrow particle size distribution products with good particle size uniformity. We can also adjust the particle size according to different requirement.

High fluidity: Good recipe and high spheroidization rate make the fluidity and filling rate high.