Loading Port:China main port

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:30 unit/month

Single Building Hoist New Lifting Machines

The hoist adopted with the normal electrical control method, is equipped with contactor, control transformer, anti-overheat protector, relay against the phase failure & disorder. All the electrical parts are equipped with Schneider and Siemens products.

The inverter, as a key controlling part, is used in the hoist adopted with VFD+PLC control method. This device is jointly developed by Japan Yaskawa and us. The hardware is supplied by Yaskawa, while the controlling software is supplied by us ensuring safe & reliable operations. PLC controller adopts OMROM products; brake unit is from YASKAWA and other electrical components are from Schneider or Siemens.

With application of VFD, it’s able to realize stepless speed regulating between zero and max speed. There are two shifting-gears set in the operating platform. One is maintenance shift, which can enable the cage run at speed of 0~5M/min for user to check the lubricating condition and connection of the machine’s parts. The other is working shift, enabling the cage with normal working speed. By adopting this control method, it’s also able to check and show the condition of power supply, operation and electrical failure. Moreover, it can avoid misoperation, giving great protection to transmission & electrical system.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

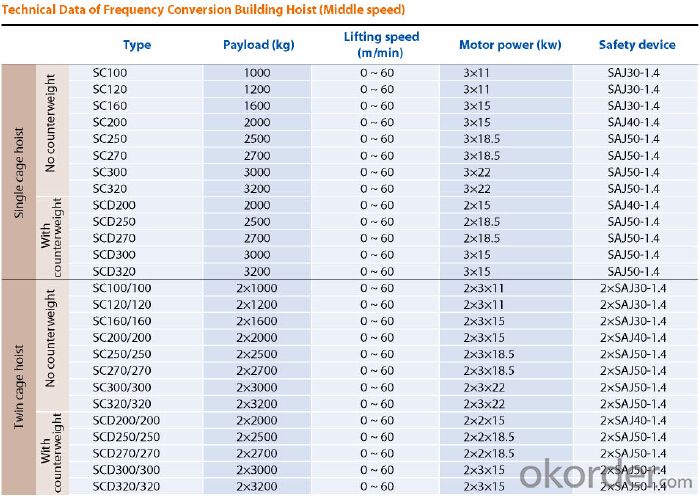

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.