Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:-

Supply Capability:-

Description:

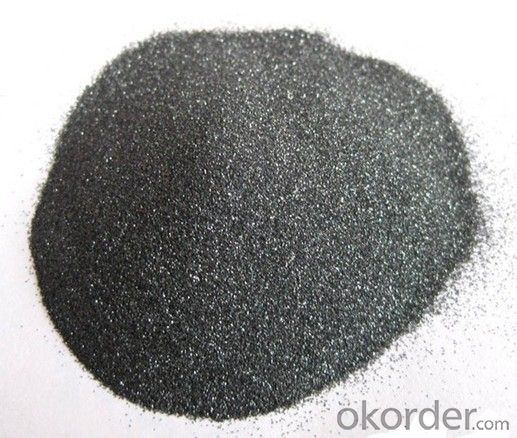

Black silicon carbide is produced at high temperature in an electric resistance type furnace with

quarts sand and petroleum coke as its main raw materials. Its hardness is between fused

alumina and synthetic diamond. Mechanical intensity of it is higher than fused alumina. It is

sharp and has electrical and heat conductivity in some degree.

Application:

Silicon carbide is widly used as refractory material and metallurgical material. It is one of the mainly materials to produce SIC refractory bricks. Black SIC is one of the most important materials in steel producing as desoxidant.

Advantages:

1. Corrosion resistance, high strength, high hardness.

2. Good wear-resisting performance,resist to shock.

3. It is a cost-effective substitute for Ferrosilicon.

4. It has Multi-functions.

5. It costs less than ferrosilicon and carbon combination.

6. It has no dust nuisance while feeding the material.

7. It can speed up the reaction.

Package: IN JUMBO BAG OR AS REQUEST

Specification:

Item | Chemical Composition | Size | |||

SiC | F.C | Fe2O3 | SiO2 | ||

Second Grade | 90.00 | 3.00 | 1.20 | 5.00 | 0-10/0-20mm |

90.00 | 3.00 | 1.20 | 5.00 | 0.5-5mm,1-5mm,1-10mm | |

88.00 | 4.00 | 1.50 | 6.00 | 0-10/0-20mm | |

88.00 | 4.00 | 1.50 | 6.00 | 0.5-5mm,1-5mm,1-10mm | |

Third Grade Crude | 85.00 | 4.50 | 1.80 | 7.00 | 0-5mm,0-10mm |

85.00 | 4.50 | 1.80 | 7.00 | 0.5-5mm,1-5mm,1-10mm | |

80.00 | 5.00 | 3.00 | 8.00 | 0-5mm,0-10mm | |

80.00 | 5.00 | 3.00 | 8.00 | 0.5-5mm | |

75.00 | 7.00 | 4.00 | 10.00 | 0-5mm,0-10mm | |

75.00 | 7.00 | 4.00 | 10.00 | 1-5mm,1-10mm | |

70.00 | 8.00 | 4.00 | 11.00 | 0-5mm,0-10mm | |

60.00 | 10.00 | 4.00 | 12.00 | 0-5mm,0-10mm | |

PICTURE: