Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

Profile

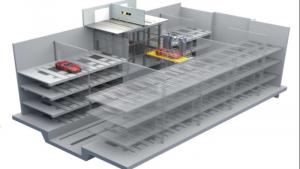

Self-Elevating Gantry Crane is similar to the U gantry crane, and the gantry structure is U gantry crane, the difference among the U gantry cranes is the leg . Because of the special working condition,some of the large lifting equipment can not enter the field, but the leg of the Self-Elevating Gantry Crane is made into several sections, and each leg has jack lifting seat. After the end beam, trolley and the main beam is assembled, the legs are connected with flanges by Jack lifting. Finally, the lower crossbeam and the running mechanism of the cart are installed.

Components

The gantry frame is the main forcing part of the crane structure which with double beam dual, the main beam, end beam, leg, saddle (with cantilever beam), the lower crossbeam is the main force part, and the auxiliary metal structure is composed of trolley track, walking platform, railing, ladder platform and other auxiliary metal structures.

The main beam is bias rail box structure or truss type structure, it analysis of girder section by the finite element method calculation system, ensure the sufficient strength, stiffness and stability. Transverse butt welding joint of main beam, end beam, outrigger, saddle, lower cross beam cover plate and web. The welding seams between the web and the cover plate are submerged arc welding or gas shielded welding. After welding, the welds are detected according to the regulations of GB/T 14406 - 1993 general gantry crane. The camber of the main beam is (1 ~ 1.4) S/1000, and the maximum camber position is controlled in the middle of the span 1/10. The main force of the main beam material is Q235-B (Q345-B), the minimum thickness is not less than 6mm.

The legs are welded with box or truss structure. The upper flange is large and the lower flange is small, so the leg becomes a variable cross-section structure with big, small and small, which can effectively load the vertical and horizontal direction. The main beam, end beam, lower beam and outriggers are connected together by high strength bolts, the reaming bolt positioning of each flange plate, located right at the factory to mark.

3mm anti-skid steel plate is used on tread of walking table of the Self-Elevating Gantry Crane, are arranged 1050mm rail height on the channel, with a distance of 350mm for horizontal bar, the 100mm height retaining plate be set in bottom, any place on the railing can withstand 1kN (100kgf) load from any direction without plastic deformation.

In order to facilitate the transportation, handling and installation, the lifting lugs, lifting holes are arranged in the main part, the strength and location of hoisting lug and hoisting hole fully consider the safety and convenience of hoisting.

Technical Specifications

Lifting Capacity | Main Hook | t | 400 |

Aux. Hook | 30 | ||

Span | m | 18 | |

Lifting Height | 18 | ||

Working Class | A4 | ||

Speed | Main Hook | m/min | 1.5 |

Aux. Hook | 6 | ||

Trolley Travelling | 10 | ||

Cart Travelling | 18 | ||

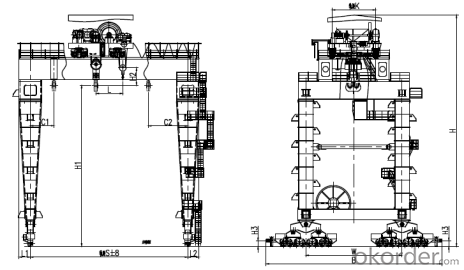

Limiting Size | L1 | mm | 1300 |

L2 | 1300 | ||

L | 2989 | ||

C1 | 270 | ||

C2 | 4500 | ||

Main Size | H | mm | 26373 |

H1 | 18000 | ||

H2 | 960 | ||

H3 | 650 | ||

B | 20100 | ||

K | 5000 | ||

W | 11000 | ||

Max. Wheel Pressure | Kn | 400 | |

Total Motor Power | Kw | 275 | |

Steel Track | QU100 | ||

Power Supply | 3-Phase A.C.50Hz 380V | ||

Features

-Lifting capacity is large, hoisting height is high.

-Super safety performance.

-Low entry fees and operating costs.

-Simple and quick installation.

-Simple and precise operation.

-Unique structure and working style.

-Low requirement for foundation.

The hoisting system has low requirements for the foundation; In general, no special treatment needs to required. The load passed will through the square steel to the bottom seat; then through the sliding beam and sleepers, steel plate and so on to expand the force area, scattered to the ground what the acceptable level can be forced.

The lifting beam can be made in various forms and in various specifications, and also can be made at any time according to the special requirements of hoisting equipment. The horizontal moving mechanism of the Self-Elevating Gantry Crane on the lifting beam can satisfy the requirements of hoisting of different equipment.