Loading Port:China main port

Payment Terms:TT or LC

Min Order Qty:2 unit

Supply Capability:500 unit/month

1. Structure of Description

High quality tin can sealing equipment

1.PLCcontrol

2.High Speed Filling Nozzle

3.material:sus304

4.aluminum/PET

Can is pushed into can holding platform one by one by feeding screw and star-wheel. Centering cup of filling valve will fall to can; the distance between filling valves and cans is sealed by springiness plastic ring. The movement of centering cup is generated by plastic idler wheel along curvilinear motion. After filled, valve will be closed, air is discharged, and centering cup will rise from the can. Filled can will be sent to conveyor chain, then to capper. Capper will take cap, turn over the edge of can and turn the edge to finish the sealing action by the control of cam. After that can is transferred to conveying system.

| Type: | Filling Machine | Condition: | New | Application: | Food,Beverage |

| Packaging Type: | Cans | Packaging Material: | Wood | Automatic Grade: | Automatic |

| Driven Type: | Electric | Voltage: | 220V/380V | | |

| | | | Certification: | CE,BV,ISO,SGS | |

| After-sales Service Provided: | Engineers available to service machinery overseas | Color: | Silver | Feature: | Automatic |

| Filling type: | Canned Drink | Name: | High quality tin can sealing equipment | Transportation: | shipping |

| Packaging Detail: | WOODEN CASE FOR High quality tin can sealing equipment |

| Delivery Detail: | 30WORKING DAYS |

2.Main features

1) Wholly sealed widow structure which is beautiful, concise, easy and highly operated;

2) Cycling tank design with precision polishing inside;

3) High precision and large flow rate filling valves to meet productive requirement;

4) Specially designed roller structure which is easy to be adjusted, locked and ensure sealing function;

5) Friendly and convenient operating panel with high expansibility.

6) The filling valve is adopts high precision mechanism valve, fast speed filling, high precision liquid level.

7) The filling vat adopts 316L material designed sealing vat, to achieve constant pressure filling.

8) The flow rate of the filling valve>125ml/s.

9) Main transmission adopts toothed belt and gearbox open-type transmission assemblies, high efficiency, low noise.

10) The main drive adopts step-less speed change for frequency conversion, the whole machine adopts PLC control; the capping machine and filling machine adopt coupling joint, to ensure synchronization of two machines.

11) With filling with can, no filling without can.

12) The filling manner is constant pressure filling, with fast filling speed and stable action.

13) Adopting introduce into full set of Switzerland (Ferrum) capping technology.

14) Capping trolley adopts high hardness alloy steel quench(HRC>62), capping curve adopts projection grinder precision machining, to ensure the quality of capping.

15) With capping with can, no capping without can control system, to ensure the normal running of the machine.

16) With CIP automatic rinsing function.

With centralized lubrication system.

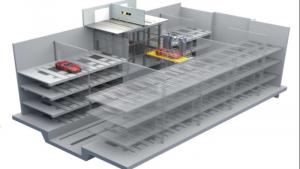

3. Images

High quality tin can sealing equipment

1.PLCcontrol

2.High Speed Filling Nozzle

3.material:sus304

4.aluminum/PET

Can is pushed into can holding platform one by one by feeding screw and star-wheel. Centering cup of filling valve will fall to can; the distance between filling valves and cans is sealed by springiness plastic ring. The movement of centering cup is generated by plastic idler wheel along curvilinear motion. After filled, valve will be closed, air is discharged, and centering cup will rise from the can. Filled can will be sent to conveyor chain, then to capper. Capper will take cap, turn over the edge of can and turn the edge to finish the sealing action by the control of cam. After that can is transferred to conveying system.