Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:5000 m²

Supply Capability:100000 m²/month

Quick DetailsType:

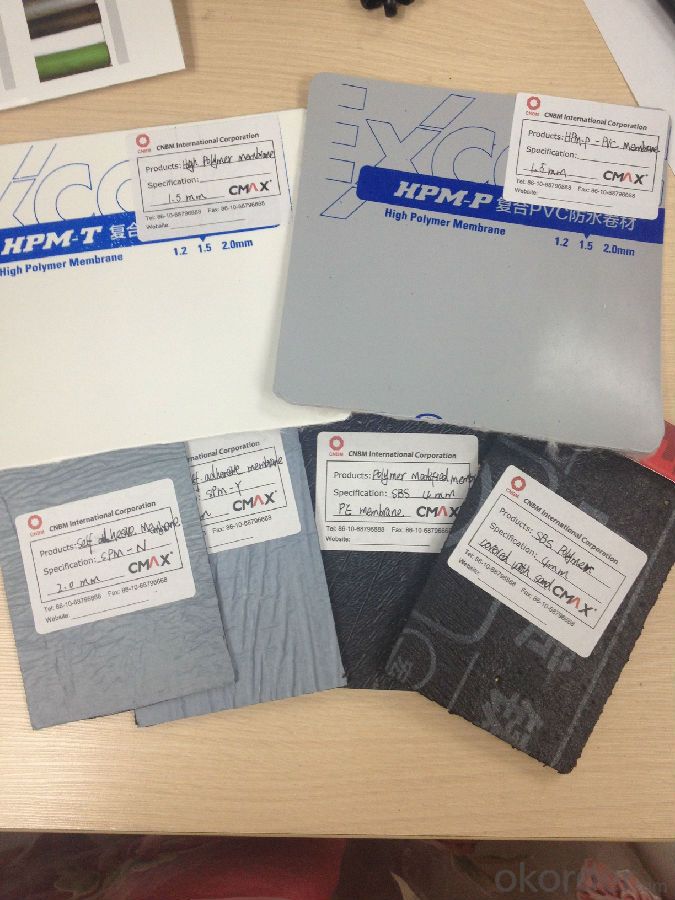

Waterproof Membrane, Waterproof membrane Place of Origin: China (Mainland)

Surface film: PE, SAND, SCHIST,aluminum Thickness: 2.0mm~5.0mm Length: 10.0m

Width: 1.0m Usage: waterproofing for roof, understand,etc

Packaging & DeliveryPackaging Details: 10 sq.m./roll export package or as requirment

Delivery Detail: 15 days after receipt of deposit.

Specifications3mm SBS modified bitumen waterproof membrane

1) 2--5mm

2) Base:PY/G

3) Surface:PE / S / M / Al

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. start application till it is dry.< span="">

2. Application Method:

Heating the bottom surface of membrane and the roof deck surface by flam spray gun or other suitable appliances till the asphalt start to melt(not flowing), then spread. Using roller to compact the membrane so that it can firmly adhere to the base surface. The overlap on the long side should be 100mm and the short side should be 150mm.

3. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

Package

Attentions for Construction

·

SBS / APP asphalt waterproof membrane, bituminous waterproof membrane

1. Membranes should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away

from sunshine and rainwater.

Installation Sketch point

Clean the substrate using broom or high pressure dusty cleaner.

Apply primer

Heat the membrane bottom using a high temperature flame gun.

Push forward while the primer and membrane oil melted

Use a roller to push hard the membrane surface to ensure it stick firmly

Application is named as "Torched on application".

1.Base processing: the base surface musts be clean,solid,level,dry;no grit,rift and loosing dust. For a large recess, fill it with cement mortar and then level it. Remove the protrusion and clean dust If working on base slab or lateral face,water lowering should be done.

2.Painting primer before laying the membrane, clean the dust on the surface of concrete base with dust catcher or dust-blower; then paint entirely with treatment agent of DY primer for waterproofing(for purpose of dust consolidation and high adhesive effect).

3.Heat to melt: place membrane correctly, fire torch, heat the membrane with base entirely, when the surface of the membrane is black and bright with a fusion layer, apply the membrane and press it into a solid and flat state.Before the membrane is cool, seal the edge of joint by float.

4.Requirements for lapping: There should be less than 3 layers of lapping, with the joint seams appearing as"T" type,avoid 4 layers of lapping.The width of longitudinal lapping is between 50 and 80mm,and of end-lap joint 100mm