Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 pc

Supply Capability:500 pc/month

Roller for Steel Rolling Mill Forged Mill Roll

Products Description

Centrifugally cast compound steel back -up rolls have a shell of cast steel with alloying elements such as Ni,Cr,Mo.After heat-treatment the roll shell get a fine temper structure, which exhibits good strength and ductility combined with high fatigue properties. When used, the roll shows a high wear and spalling resistance all the time.

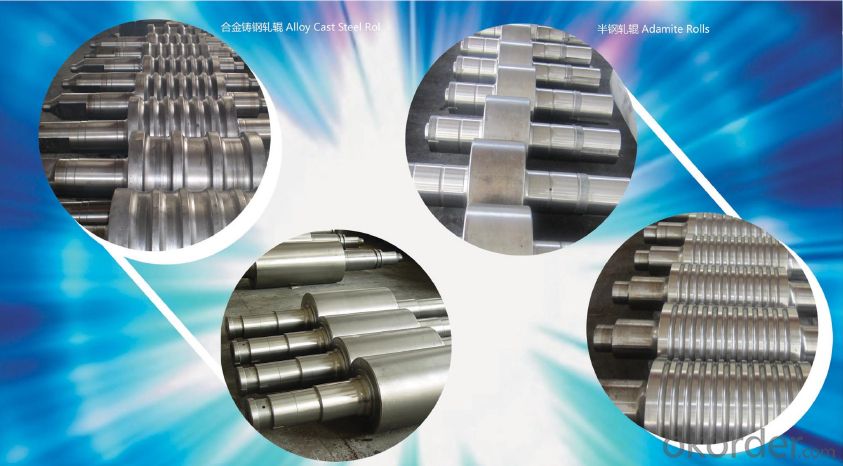

Products Pictures

Chemical Composition:

Classification | C | Si | Mn | P | S | Ni | Cr | Mo |

CrMo semi-chilled nodular cast iron rolls | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.20-0.60 | 0.20-0.60 | |

CrMo indefinite chilled nodular cast iron rolls | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.20-0.60 | 0.20-0.60 | |

NiCrMo indefinite chilled nodular castiron rolls(Ⅰ) | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.50-1.00 | 0.20-0.60 | 0.20-0.80 |

NiCrMo indefinite chilled nodular castiron rolls(Ⅱ) | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 1.01-2.00 | 0.30-1.20 | 0.20-0.80 |

Nodular pearlitic rolls(SGPI) | 2.90-3.60 | 1.40-2.20 | 0.40-1.00 | ≤0.15 | ≤0.03 | 1.50-2.00 | 0.10-0.60 | 0.20-0.80 |

Nodular pearlitic rolls(SGPⅡ) | 2.90-3.60 | 1.20-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 2.01-2.50 | 0.20-1.00 | 0.20-0.80 |

Nodular pearlitic rolls(SGP Ⅲ) | 2.90-3.60 | 1.00-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 2.51-3.00 | 0.20-1.00 | 0.20-0.80 |

Centrifugally acicular nodular cast iron rolls(SGAⅠ) | 2.90-3.60 | 1.20-2.20 | 0.20-0.80 | ≤0.10 | ≤0.03 | 3.01-3.50 | 0.20-1.00 | 0.50-1.00 |

Centrifugally acicular nodular cast iron rolls(SGAⅡ) | 2.90-3.60 | 1.00-2.00 | 0.20-0.80 | ≤0.10 | ≤0.03 | 3.51-4.50 | 0.30-1.50 | 0.50-1.00 |

NiMo nodular cast iron roll( Ⅰ) | 2.90-3.50 | 1.50-2.40 | 0.40-0.80 | ≤0.05 | ≤0.03 | 1.00-2.50 | 0.10-0.50 | 0.40-0.80 |

NiMo nodular cast iron roll( Ⅱ) | 2.90-3.50 | 1.20-2.40 | 0.40-0.80 | ≤0.10 | ≤0.03 | 2.51-3.50 | 0.10-0.50 | 0.40-1.00 |

Physical Performance:

Products | Barrel Hardness (HSD) | Neck Hardness (HSD) | Tensile Strength (Mpa) |

CrMo semi-chilled nodular cast iron rolls | 40-55 | 35-55 | >300 |

CrMo indefinite chilled nodular cast iron rolls | 55-70 | 35-55 | >300 |

NiCrMo indefinite chilled nodular cast iron rolls(Ⅰ) | 55-70 | 35-55 | >300 |

NiCrMo indefinite chilled nodular cast iron rolls (Ⅱ) | 60-70 | 35-55 | >300 |

Nodular pearlitic rolls (SGPI) | 60-70 | 35-55 | >450 |

Nodular pearlitic rolls (SGPⅡ) | 55-65 | 35-55 | >450 |

Nodular pearlitic rolls (SGP Ⅲ) | 62-72 | 35-55 | >450 |

Centrifugally acicular nodular cast iron rolls(SGAⅠ) | 55-78 | 32-45 | >350 |

Centrifugally acicular nodular cast iron rolls(SGAⅡ) | 55-78 | 32-45 | >350 |

NiMo nodular cast iron roll( Ⅰ) | 42-52 | 32-43 | >300 |

NiMo nodular cast iron roll( Ⅱ) | 42-52 | 32-43 | >300 |

Quotation Elements

| ITEM | QUOTATION ELEMENTS |

1 | What kind of products the factory produce? Hot Rolled Steel Coil? Cold Rolled Steel Coil? Wire Rod? Rebar? |

2 | Production Process of Roll --Cast or Forged |

3 | Grade of Roll |

4 | Chemical Composition of Roll |

5 | Physical Property of Roll: Hardness/Tensile Strength/Elogation/Bening Strength |

6 | Drawing of Roll |

7 | Quantity |

8 | Delivery time |

Quality Control and Package

Products Display