Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

Sandwich panels for building applications are large prefabricated building products.

Sandwich panels generally consist of two outer metal sheets (steel, aluminium, other) with a stabilizing core of insulation sandwiched between them. The metal sheets are bonded to the insulation core with specialised adhesives. The outer surface of the sheets can be flat, slightly corrugated or with a significant profile (eg. for roofs or external façade design). A huge assortment of shapes, coatings and colours is available. Because sandwich panel installation requires only a limited number of mechanical fasteners (eg. screws), the resulting constructions avoid significant thermal bridging. To achieve distinctive architectural features, panels with hidden joints are available.

Since 2009 a new European standard EN 14509 has defined the regulation and quality of sandwich panels with insulating core materials.

At ROCKWOOL our sandwich panel specialists are trained to support sandwich panel producers and other component suppliers to achieve maximum panel performance. For many years ROCKWOOL has developed and supplied robust insulation core materials for sandwich panel solutions worldwide

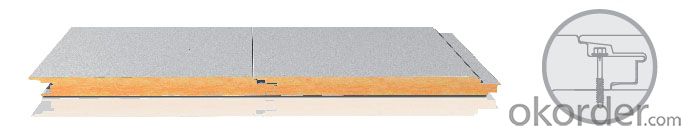

Rock wool composite wall panel system (vertical) -- MQ1-T-W

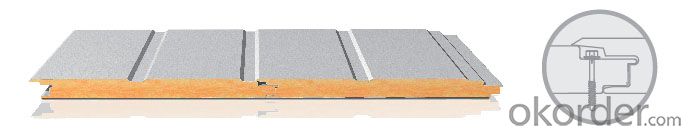

Rock wool composite wall panel system (horizontal) -- MQ2-T-W

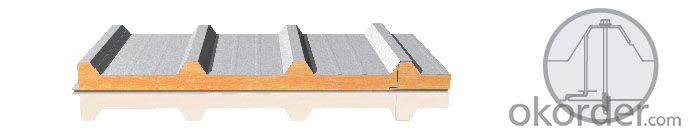

Rock wool composite wall panel system (horizontal) -- MQ3-T-W

panel thickness T=50mm 80mm 100mm 120mm 150mm

panel width W=600mm-1000mm

Rock wool composite roof system -- MW1-T-W

Xinxin's rock wool sandwich panle with two layers of color steel bonded and a high density rock wool fire proofing, insulation core material formed in the middle as a whole, can be widely used in a fire, sound and heat insulation requirements of public, business and indestrial constrction.

panel thickness T=50mm 80mm 100mm 120mm 150mm

panel width W=1000mm

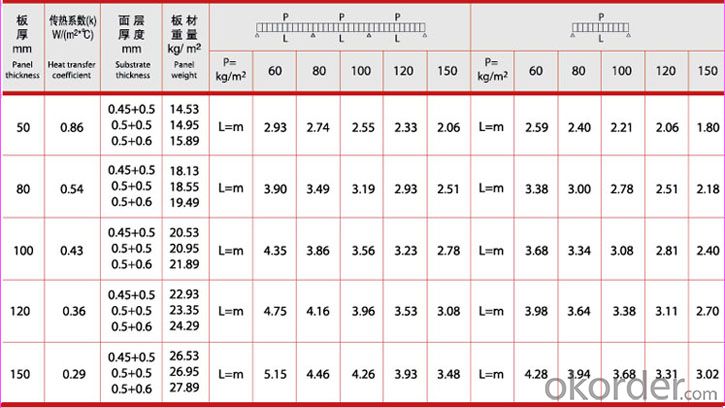

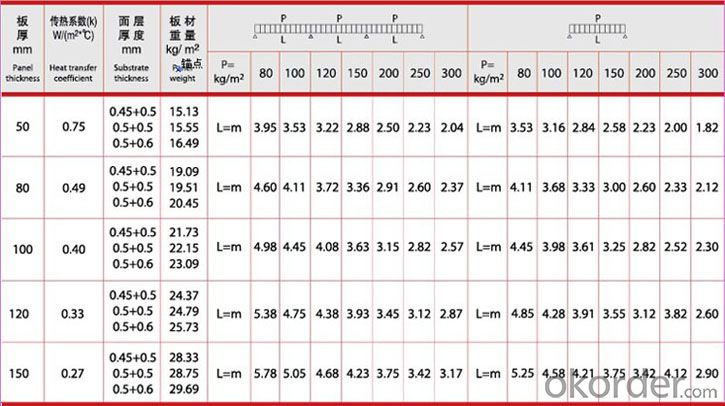

Metal surface rock wool sandwich panel design specifications

1.Wall plate allows vertical load, span, heat transfer coefficient (Allowable Distortions f≤L/240)

Core density = 120 kg/m3

2.Roof plate allows vertical load, span, heat transfer coefficient (Allowable Distortions f≤L/200)

Core density = 120 kg/m3