Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:10 set

Supply Capability:100 set/month

| Packaging Detail: | hongsen package/neutral package |

| Delivery Detail: | one week |

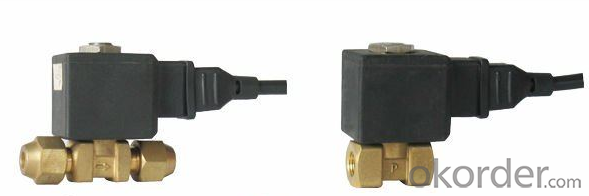

1.refrigeration solenoid valve magnetic valve coil

2.perfect sealing performance;one direction flow;valve body is universal

Refrigeration Solenoid Valve Magnetic Valve Coil

· Model EVR solenoid valve is a direct-operated or servo-operated valve,which is applicable to one direction flow.

· Model EVR solenoid valve is used on the liquid, air suction or hot vaporpiping of a freezer, cold store and air conditioning unit.

· The valve seat of Model EVR solenoid valve is well sealed with perfectsealing performance.

· Model EVR solenoid valves with various voltage solenoids are availableand the valve body is universal.

· Both packed and separated Model EVR solenoid valves are available andit means the valve body could be supplied separately from the solenoid.

Features:

· Only NC type solenoid valve is available.

· The max. design temperature is 105°C.

· 100-mesh filter is contained at the suction end, which is replaceable.

· 10W high power solenoid and max. operating pressure differential

· (MOPD) is 2.5 MPa.

· It is applicable to various applications in freezer, cold store and air conditioning unit.

· The max. size of flare connection is 3/4 in.

· The max. size of welded connection is 9/8 in.

· The solenoids with various power supply are available.

· The clamped joint solenoid is easy to be mounted or dismounted only with one screwdriver.

· The sealed solenoid has a long service life and it can be used even in an adverse circumstance.

Technical Paramengers:

| Applicable Refrigerant | HCFC or HFC (Customer choice) |

| Applicable Medium Temperature | -25°C~+105°C |

| Applicable Ambient Temperature of Solenoid | -25°C~+80°C |

| Standard Voltage of Solenoid | AC380V,AC220V/50Hz(Custom design is acailable) |

| Allowable Voltage Fluctuation for Solenoid | +10%~-15% |

| Connection of Solenoid | IP67 with terminal box |

Specification:

| Model | Connection Type | P(bar) | Max.Operating Pressure(bar) | Kv(m3/h) | ||

| Flare | Welded | Min. | Max.MOPD Liquid | |||

| EVR3-2 | 1/4 SAE | 1/4 ODF | 0.0 | 30 | 40 | 0.27 |

| EVR3-3 | 3/8 SAE | 3/8 ODF | 0.0 | 0.27 | ||

| EVR6-3 | 3/8 SAE | 3/8 ODF | 0.05 | 0.8 | ||

| EVR6-4 | 1/2 SAE | 1/2 ODF | 0.8 | |||

| EVR10-4 | 1/2 SAE | 1/2 ODF | 1.9 | |||

| EVR10-5 | 5/8 SAE | 5/8 ODF | 1.9 | |||

| EVR15-5 | 5/8 SAE | 5/8 ODF | 2.6 | |||

| EVR15-6 | 3/4 SAE | 3/4 ODF | 2.6 | |||

| EVR15-7 | -- | 7/8 ODF | 2.6 | |||

| EVR20-7 | -- | 7/8 ODF | 5.0 | |||

| EVR20-9 | -- | ODF | 5.0 | |||

| EVR25-9 | -- | ODF | 0.2 | 10.5 | ||

| EVR25-11 | -- | ODF | ||||

| EVR32-11 | -- | ODF | 16 | |||

| EVR32-13 | -- | ODF | ||||

| EVR40-13 | -- | ODF | 21 | |||

| EVR40-17 | -- | ODF | ||||

1)Kv:The flow rate (m3/h)of water of density 1 t/m3 passing through the solenoid valve under the pressure differential of 100 KPa.

2)The MOPD of gaseous medium is about 0.1 MPa higher than that of liquid.

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.