Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:10 m.t.

Supply Capability:1000 m.t./month

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | Uncertain | Al2O3 Content (%): | ≥60% | MgO Content (%): | Uncertain |

| CaO Content (%): | Uncertain | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | Uncertain |

| SiC Content (%): | Uncertain | Model Number: | LNHAB14001 | Brand Name: | |

| Apparent porosity,%: | 18-22% | Cold Crushing strength Mpa: | 45-80Mpa | Fe2O3 %: | ≤2.0% |

| Sample Request: | Free | Advantage 1: | The most competitive price | Advantage 2: | Abundant Experience |

| Advantage 3: | Different Moulds. Save mould fees for you | Advantage 4: | Large stocks. Guarantee prompt delivery | Advantage 5: | Professional Packing |

| Advantage 6: | Lower ferric Oxide,porosity,density,higher CCS and exact tolerance |

| Packaging Details: | Packed on wooden pallets with water-proof cover, and tightened with plastic/steel bandages |

| Delivery Detail: | In 20 days after prepay |

Resisting high temperature

2.Great bulk density

3.Low iron content

4.Good eroding resistance

5.ISO certificate

Description:

High alumina bricks are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. It features excellent high temperature mechanics and chemical corrosion resistance.

Features

1.Resisting high temperature

2.Great bulk density

3.Low iron content

4.Good eroding resistance

Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Specifications:

Ordinary High alumina brick

Item | HA60 | HA70 | HA75 | HA80 |

AL2O3(%) | ≥60 | ≥70 | ≥75 | ≥75-80 |

SIO2(%) | 32 | 22 | 20 | ≥18 |

Fe2O3(%) | ≤1.8 | ≤1.8 | ≤1.8 | ≤1.8 |

Refractoriness °C | 1790 | >1800 | >1825 | ≥1850 |

Bulk density,g/cm3 | 2.4 | 2.45-2.5 | 2.5 | 2.55-2.6 |

Softening temperature under load | ≥1470 | ≥1520 | ≥1530 | ≥1550 |

Apparent porosity,% | 22 | <21 | <21 | <20 |

Cold Crushing strength Mpa | ≥45 | ≥50 | ≥54 | ≥60 |

Phosphate bonded high alumina bricks

Item | L75 | L77 | L85 |

AL2O3 % | ≥75 | ≥77 | ≥80-85 |

Fe2O3 % | ≤3.0 | ≤3.0 | ≤1.8 |

Ca0 % | ≤0.6 | ≤0.6 | ≤0.6 |

Refractoriness °C | ≥1800 | ≥1800 | ≥1850 |

Bulk density g/cm3 | ≥2.65 | ≥2.70 | ≥2.80 |

Cold crushing strength MPa | ≥60 | ≥64 | ≥110 |

Refractoriness under load 0.2MPa °C | ≥1350 | ≥1300 | ≥1350 |

Application | Used for high temperature parts lining of cement rotary kiln | Used for Badly worn parts of cement rotary kiln | |

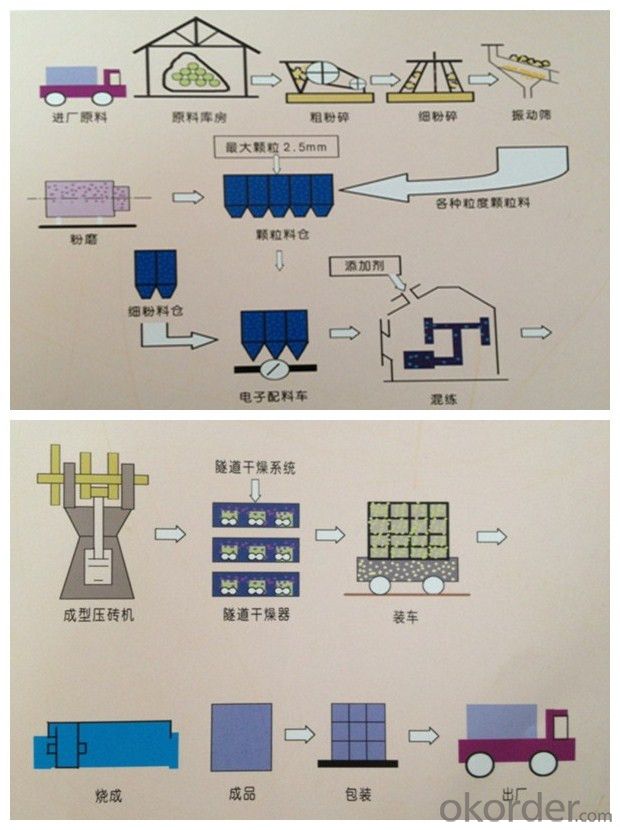

Process flowdiagram:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

FAQ

1.Are you a manufacturer or trader?

Factory + trade (mainly factories, at the same time, we operates other related products)

2.Can we visit your factory?

Sure,welcome at any time,seeing is believing

3.What's the MOQ of trial order ?

No limit,We can offer the best suggestions and solutions according to your condition.

4.Which payment terms are you accept?

T/T,LC,Western Union,moneygram,Paypal are available for us.

5.After an order is placed, when to deliver?

15-25days

6.Is your company accept customization?

We have own factory and excellent technical team, and we accept OEM service.

7.How about your company's certification?

SGS,ISO9001 and Test Report,also we could apply other necessary certification.

8.How to solve the quality problems?

If the products are not conform to customer samples or have quality problems, our company will be responsible to make compensation for it.