Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:1 set/month

Profile

QY Model 5t-50/10t Insulated Hanged Overhead Crane is suitable for non-ferrous metal electrolytic aluminum, magnesium, lead, zinc and other smelting workshop. In order to prevent the electric current in the process of working on the electrified parts through the lifting hook to the crane to threaten the driver and equipment’s safety, so in the proper positions of the crane set up three insulation devices.

Feature

Lifting adopts double brakes, safe and reliable.

The hoisting mechanism (motor, reducer, brake, reel, fixed pulley, etc.) and the trolley frame adopts insulation plate or insulation sleeve.

The lifting hook is insulated hook group.

The wheels of the trolley mechanism adopts insulated wheel group.

Technical Specifications

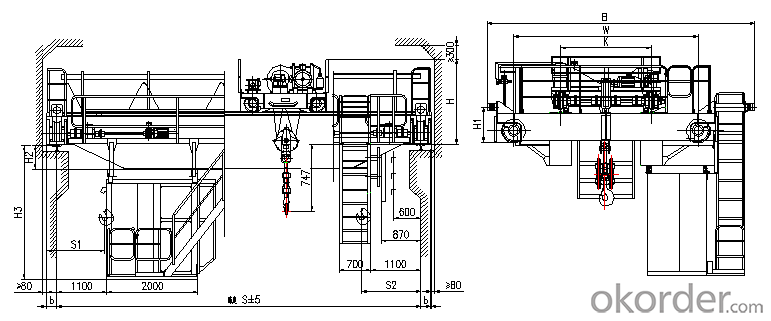

5t-10t Insulated Hanged Overhead Crane

Lifting Capacity | t | 5 | 10 | ||||||||||||||||||

Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | ||||

Max. Lifting Height | m | 16 | 16 | ||||||||||||||||||

Working Class | A6 | A6 | |||||||||||||||||||

Speed | Lifting | m/ min | 15.6 | 13.3 | |||||||||||||||||

Trolley Travelling | 37.2 | 43.8 | |||||||||||||||||||

Cart Travelling | 115.6 | 116.8 | 115.6 | 116.8 | 112.5 | ||||||||||||||||

Main Size | B | mm | 5150 | 5204 | 6264 | 5704 | 5934 | 6504 | |||||||||||||

W | 3400 | 3550 | 5000 | 4050 | 5000 | ||||||||||||||||

S1 | 800 | 1050 | |||||||||||||||||||

S2 | 1250 | 1300 | |||||||||||||||||||

b | 230 | 230 | |||||||||||||||||||

K | 1400 | 2000 | |||||||||||||||||||

H | 1764 | 1876 | 1926 | ||||||||||||||||||

H1 | 765+H0 | 800+H0 | 800+H0 | 850+H0 | |||||||||||||||||

H2 | -24 | 126 | 226 | 376 | 526 | 676 | 826 | 976 | -24 | 126 | 226 | 376 | 526 | 628 | 778 | 928 | |||||

H3 | 2526 | 2546 | 2596 | 2756 | 2906 | 3056 | 3206 | 3356 | 2526 | 2546 | 2596 | 2756 | 2906 | 3008 | 3158 | 3308 | |||||

Max Wheel Pressure | kN | 78 | 83 | 89 | 96 | 103 | 114 | 123 | 129 | 107 | 114 | 123 | 128 | 137 | 147 | 155 | 165 | ||||

Steel Track | kg/m | 43 | 43 | ||||||||||||||||||

Power Supply | 3-Phases A.C, 50Hz 380V | ||||||||||||||||||||

Note:H0≤250 is the added height of the buffer of crane | |||||||||||||||||||||

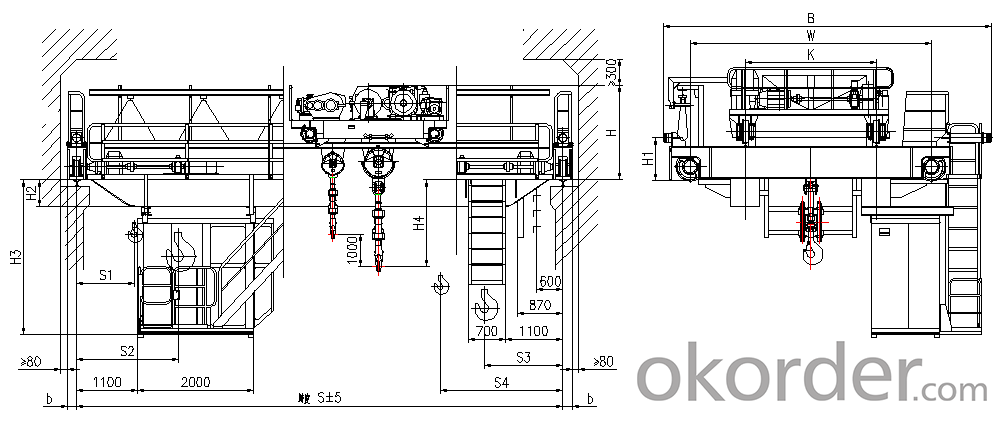

16-20t Insulated Hanged Overhead Crane

Lifting Capacity | t | 16/3.2 | 20/5 | ||||||||||||||||||||||

Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | ||||||||

Max.lifting height | Main | m | 16 | 12 | |||||||||||||||||||||

Auxiliary | 18 | 14 | |||||||||||||||||||||||

Working Class | A6 | A6 | |||||||||||||||||||||||

Speed | Main lifting | m/ min | 13 | 9.7 | |||||||||||||||||||||

Auxiliary lifting | 14.5 | 12.7 | |||||||||||||||||||||||

Trolley traveling | 44.6 | 44.6 | |||||||||||||||||||||||

Crane traveling | 112.5 | 101.4 | 112.5 | 101.4 | |||||||||||||||||||||

Main dimension | B | mm | 6274 | 7004 | 6274 | 7004 | |||||||||||||||||||

W | 4400 | 5000 | 4400 | 5000 | |||||||||||||||||||||

S1 | 1040 | 1030 | |||||||||||||||||||||||

S2 | 1850 | 1900 | |||||||||||||||||||||||

S3 | 2310 | 2320 | |||||||||||||||||||||||

S4 | 1500 | 1450 | |||||||||||||||||||||||

b | 230 | 260 | 230 | 260 | |||||||||||||||||||||

H | 2095 | 2097 | 2187 | 2185 | 2097 | 2099 | 2189 | ||||||||||||||||||

H1 | 850+H0 | 940+H0 | 850+H0 | 940+H0 | |||||||||||||||||||||

H2 | 80 | 180 | 240 | 390 | 540 | 690 | 840 | 80 | 84 | 184 | 244 | 392 | 542 | 692 | 842 | ||||||||||

H3 | 2570 | 2550 | 2620 | 2770 | 2920 | 3070 | 3220 | 2570 | 2574 | 2554 | 2624 | 2772 | 2922 | 3072 | 3222 | ||||||||||

H4 | 1527 | 1525 | 1435 | 1437 | 1461 | 1459 | 1369 | ||||||||||||||||||

Max. Wheel load | kN | 150 | 157 | 165 | 177 | 185 | 196 | 206 | 216 | 172 | 179 | 188 | 202 | 210 | 223 | 234 | 244 | ||||||||

Recommended steel rail | 43kg/m or QU70 | ||||||||||||||||||||||||

Power source | 3P A.C 50Hz 380V | ||||||||||||||||||||||||

Note:H0≤250 is the added height of the buffer of crane | |||||||||||||||||||||||||

Component

Bridge

The bridge is the main force component of the crane. The double beam double track structure is adopted. The main beam and the end beam are the main force parts, and the auxiliary metal structure is composed of trolley track, walking platform, railing, ladder and so on.

The main weld is submerged arc welding or gas shielded welding. After welding, the welds are detected according to the regulations of GB/T 14405 - 2011 general bridge crane. The main force material is Q235B, and the main beam section adopts ANSYS finite element calculating method to analyze and calculate systematic to ensure that it has sufficient strength, stiffness and overall stability. All steel plates did ball blast pretreatment, reaching Sa2.5 grade standard.

The camber ratio is (0.9 ~ 1.4) S/1000, and the maximum camber position is controlled in the middle of the span 1/10. The end beam is a box structure, and the end beam is connected with the main beam as rigid connection. The end beam needs to be transported after disassembly, and it is connected by high strength bolts, and the connection plate is positioned by reaming bolts. The walking platform of bridge with 3mm thick tread plate, channels are set up for 1050mm high railing, with a distance of 350mm for horizontal bar, the bottom height of retaining plate is 100mm, any place on the railing can withstand the load of 1kN (100kgf) from any direction without plastic deformation. In order to facilitate transportation, loading and unloading, installation, the main components are equipped with hoisting lug, hoisting hole, etc., the hoisting lug, hoisting hole strength and location need to fully consider the safety and convenience of lifting.

- Hoisting Mechanism

The motor drive, through the reducer speed change drive drum, and the wire rope winding system to complete the lifting of the hook. The brake of hoisting mechanism adopts the scheme of electric braking and support braking, and the braking is stable, safe and reliable. The components of the hoisting mechanism are compact and convenient to maintain. The insulated device be set between the lifting hook and the movable pulley block, also between the hoisting mechanism and the trolley frame, each insulating state at room temperature (temperature 20℃ to 25 ℃, the humidity resistance is less than or equal to 80%) with the 1000V megameter measured value should be greater than or equal to 1MΩ.

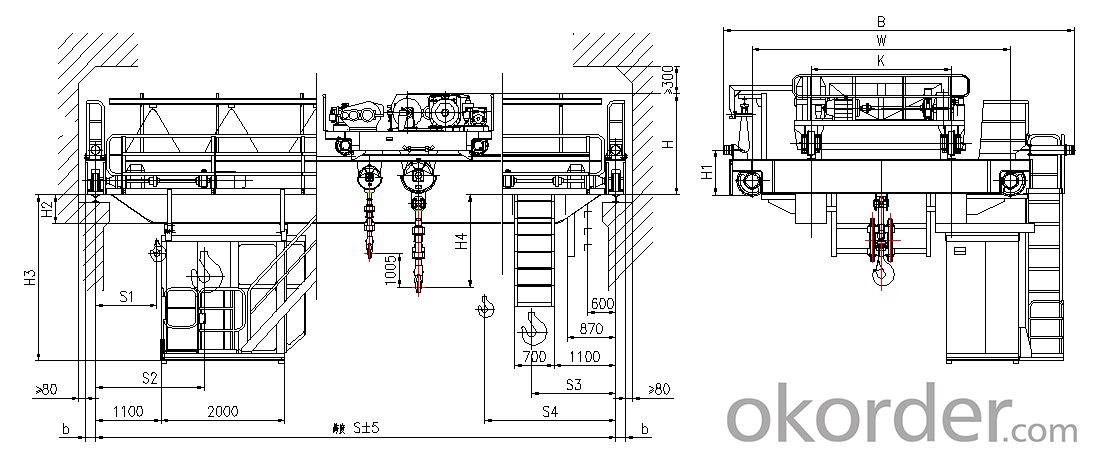

32-50t Insulated Hanged Overhead Crane

Lifting Capacity | t | 32/5 | 50/10 | ||||||||||||||||||||||

Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | ||||||||

Max.lifting height | Main | m | 16 | 12 | |||||||||||||||||||||

Auxiliary | 18 | 14 | |||||||||||||||||||||||

Working classification | A6 | A6 | |||||||||||||||||||||||

Speed | Main lifting | m/ min | 9.5 | 7.8 | |||||||||||||||||||||

Auxiliary lifting | 12.7 | 13.2 | |||||||||||||||||||||||

Trolley traveling | 42.4 | 38.5 | |||||||||||||||||||||||

Crane traveling | 101.4 | 101.8 | 86.8 | 86.6 | 87.3 | ||||||||||||||||||||

Main dimension | B | mm | 6574 | 6744 | 7044 | 6944 | 7024 | ||||||||||||||||||

W | 4650 | 4700 | 5000 | 4800 | 5000 | ||||||||||||||||||||

S1 | 1070 | 1005 | |||||||||||||||||||||||

S2 | 2050 | 2200 | |||||||||||||||||||||||

S3 | 2680 | 3195 | |||||||||||||||||||||||

S4 | 1700 | 2000 | |||||||||||||||||||||||

b | 260 | 300 | 300 | ||||||||||||||||||||||

K | 2500 | 2500 | |||||||||||||||||||||||

H | 2363 | 2367 | 2497 | 2746 | 2748 | 2754 | |||||||||||||||||||

H1 | 940+H0 | 1070+H0 | 1090+H0 | 1130+H0 | |||||||||||||||||||||

H2 | 90 | 96 | 246 | 266 | 416 | 566 | 716 | 816 | -79 | 98 | 104 | 254 | 404 | 554 | 704 | 804 | |||||||||

H3 | 2580 | 2586 | 2616 | 2646 | 2796 | 2946 | 3096 | 3196 | 2531 | 2528 | 2534 | 2634 | 2784 | 2934 | 3084 | 3184 | |||||||||

H4 | 1553 | 1549 | 1419 | 1421 | 1920 | 1918 | 1912 | ||||||||||||||||||

Max. Wheel load | kN | 246 | 259 | 272 | 289 | 303 | 316 | 326 | 339 | 340 | 361 | 381 | 399 | 414 | 432 | 445 | 461 | ||||||||

Recommended steel rail | QU70 or square steel 90 | QU80 or square steel 100 | |||||||||||||||||||||||

Power source | Three phase AC 380V 50Hz | ||||||||||||||||||||||||

Note:H0≤250 is the added height of the buffer of crane | |||||||||||||||||||||||||

-Safety device

All of the main lifting mechanisms and auxiliary lifting mechanisms of the QY model 5t-50/10t insulated hanged overhead crane have overload limiter. The overload limiter will send a indicated alerting signal once the load has reached 90% of the rated lifting capacity. It will send a delayed alarm once the load has reached 105% of the rated lifting capacity. Once the load has reached 110% of the rated lifting capacity, then it will cut off the power source for raising power automatically. In the meanwhile, it will send a prohibitive alerting signal. In the cab of the QY model 5t-50/10t insulated hanged overhead crane, it will monitor the the number of the lifting capacity lively.

In according to the safety rules of the lifting machinery, each exposed rotating part with the possibility of hurting person need to be installed with protective cover and anti-drop device for steel wire rope. The pattern of the protective cover is detachable.

The design and manufacturing of the platform, walkway and escalator should be in line with national safety rules and standard. In this way, it aims to maintain and check convenient for operator. The manufacturing of the foot board of the ladder and the outside platform should have the function of skid resistance. And then, the width of the walk board, platform and ladder is no less than 500mm. The walk board adopts mild steel checkered plate.

The lifting height limitator and traveling normal limit switch should be installed on the QY model 5t-50/10t insulated hanged overhead crane. By means of electrical control, it can realize safety protection for the operation position and motion displacement.

Shocker absorber and other absorber devices are installed in the QY model 5t-50/10t insulated hanged overhead crane, which aims to buffer the kinetic energy caused by running braking of the QY model 5t-50/10t insulated hanged overhead crane. In the meanwhile, the stop devices have been installed on the limiting position of all of the traveling mechanisms. It aims to prevent the the QY model 5t-50/10t insulated hanged overhead crane from falling on the limiting position.

The device for sweeping the rail has been set on the QY model 5t-50/10t insulated hanged overhead crane, which aims to clean the cats and dogs on the traveling rail. It prevents the QY model 5t-50/10t insulated hanged overhead crane from derailing caused by the cats and dogs on the rail.

On the door of the handrail and cab of the QY model 5t-50/10t insulated hanged overhead crane are set with electrical interlock protection system, it can cut off the power source of the mechanism which will hurt the person.

Electrical parts the QY model 5t-50/10t insulated hanged overhead crane are installed with default phase protection, phase dislocation protection, zero position protection, under voltage and over voltage protection, short-circuit protection, over current protection, ground protection and other electrical protections, which can insure the QY model 5t-50/10t insulated hanged overhead crane operated in a stable and safe conditions.