Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

QD Type 5~125t Overhead Crane with Hook

This kind of product is suitable for all kinds of common operating conditions, which are used to handle the material, install the equipment and maintain the equipment. It is the most widely used general lifting equipment. Such as, it is used in machinery manufacturing, assembling, petrochemical , warehouse logistics, electric power construction and etc.

This kind of product adopts double girders and double rails, individual trolley with winch. It has many advantages, such as simple structure, mature technology, stable performance, convenient manipulation, convenient maintenance and installation, high adaptive ability under all kinds of various working conditions, low price and etc, which attract the attention of the user greatly.

Main feature of the QD Type 5~125t Overhead Crane with Hook

The QD type 5~125t overhead crane with hook adopts center rail, narrow box type double girder bridge. It is the most common used structural pattern. It has following advantages, such as high strength, great rigidity, convenient maintenance and manufacturing.

The QD type 5~125t overhead crane with hook has the feature of simple structure. Also, it is easy to install and dismount. It is easy to maintenance daily.

It has a high degree of standardization of spare parts. It has a high universality. It has a low price, which is convenient to purchase.

QD Type 150t and over 150t Overhead Crane with Hook

The QD Type 150t and over 150t Overhead crane with hook is developed on the basic of 5~125t overhead crane with hook. It is designed and developed for satisfying the requirement of the large tonnage overhead crane. This kind of overhead crane with hook has a bulky structure, complex manufacturing. Also, it is difficult to transport and install. Bigger the tonnage of crane is, more difficult the described is. It requires that the manufacture has the strong ability in designing and manufacturing. The tonnage of the overhead crane is an important signal of manufacturing strength of the manufacturer.

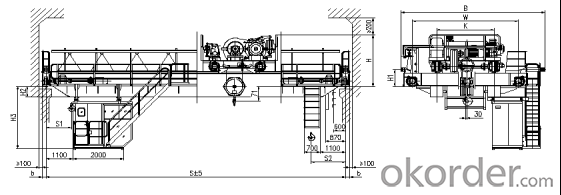

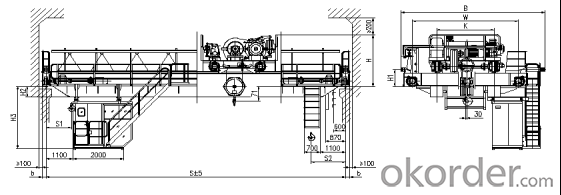

Sketch

5t Overhead Crane with Hook

Technical Specifications

Lifting capacity | t | 5 | 5 | ||||||||||||||||||||

Span S | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | ||||||

Max.lifting height | m | 16 | 16 | ||||||||||||||||||||

Classification | A5 | A6 | |||||||||||||||||||||

Speed | Hoisting | m/ min | 12.5 | 15.5 | |||||||||||||||||||

Trolley traveling | 37.2 | 37.2 | |||||||||||||||||||||

Crane traveling | 90.7 | 91.9 | 115.6 | 116.8 | |||||||||||||||||||

Main dimension | S1 | mm | 800 | 800 | |||||||||||||||||||

S2 | 1250 | 1250 | |||||||||||||||||||||

H | 1831 | 1831 | |||||||||||||||||||||

H1 | 765 | 765 | 800 | ||||||||||||||||||||

H2 | -24 | 126 | 226 | 376 | 526 | 676 | 826 | 976 | -24 | 126 | 226 | 376 | 526 | 676 | 826 | 976 | |||||||

H3 | 2546 | 2546 | 2646 | 2796 | 2946 | 3096 | 3246 | 3396 | 2546 | 2546 | 2646 | 2796 | 2946 | 3096 | 3246 | 3396 | |||||||

K | 1400 | 1400 | |||||||||||||||||||||

W | 3400 | 3550 | 5000 | 3400 | 3550 | 5000 | |||||||||||||||||

B | 5254 | 5304 | 5948 | 5254 | 5304 | 5948 | |||||||||||||||||

b | 230 | 230 | |||||||||||||||||||||

Max. Wheel load | kN | 72 | 78 | 84 | 92 | 97 | 109 | 117 | 124 | 73 | 79 | 85 | 93 | 98 | 110 | 118 | 125 | ||||||

Total motor power | Kw | 22.8 | 27.4 | 27.8 | 31.8 | ||||||||||||||||||

Recommended steel rail | kg/m | 43kg/m | |||||||||||||||||||||

Power source | 3-Phase A.C. 50Hz 380V | ||||||||||||||||||||||

600/150t~800/150t Overhead Crane with Hook

Technical Specifications

Lifting capacity | Main hoisting | t | 600 | 800 | |

Auxiliary hoisting | t | 150 | 150 | ||

Span S | m | 34 | 34 | ||

Max.lifting height | Main hoisting | m | 24 | 26 | |

Auxiliary hoisting | 26 | 28 | |||

Classification | A5 | A5 | |||

Speed | Main hoisting | m/ min | 0.17~1.7 | 0.15~1.5 | |

Auxiliary hoisting | 0.41~4.1 | 0.41~4.1 | |||

Trolley traveling | 1.5~15 | 1.3~13 | |||

Crane traveling | 3.6~36 | 3.1~31 | |||

Main dimension | L1 | mm | 1600 | 1900 | |

L2 | 3600 | 4000 | |||

L | 2850 | 3050 | |||

h | 1200 | 1300 | |||

h1 | 770 | 1270 | |||

H | 6300 | 7350 | |||

H1 | 3050 | 3220 | |||

B | 12000 | 13900 | |||

K | 5600 | 6800 | |||

B1 | 500 | 550 | |||

Max. Wheel load | kN | 980 | 840 | ||

Total motor power | Kw | 466 | 588 | ||

Recommended steel rail | kg/m | QU120 | |||

Power source | 3-Phase A.C. 50Hz 380V | ||||

Main feature of QD Type 150t and over 150t Overhead Crane with Hook

It adopts bias-rail and wide box double girder bridge, which has a large loading capacity and great stability.

It adopts car structure. It has a balance wheel load of wheel, which has a clear structural stress.

The traveling mechanism of the crane is installed inner the main girder, which adopts universal coupling torque.

The electronic components is installed inner the main girder, which can prevent the electronic components from influencing by bad working environment.

Bridge

Bridge is the main stress components of the overhead crane, which adopts double girders and double rails pattern. The main stress component contains main girder and end girder. Also the auxiliary stress component includes track of the trolley, walking board, handrail, ladder and other mental structure.

The main welding joint adopts gas shield welding or submerge arc welding. After it has be welded, it must be check the welding joint in line with GB/T 14405—2011 general-purpose overhead crane.

The materials of the main stress component adopts Q235B. The cross section of the main girder adopts ANSYS finite element calculation methods to calculate and analyse, which aims to ensure the the stress component having enough strength, rigidity and stability of whole overhead crane.

All of the steel plate should be experienced shot blasting, which can reach Sa2.5 standard

The deflection upwards should be(0.9~1.4)S/1000. Then, the position of max deflection upward should be controlled in the middle span of 1/10.

The end girder is box structure. The end girder and main girder is connected by rigid connection. The end girder is transported disassembly methods. It adopts high-strength bolt to connect. The junction plate adopts reaming bolt to fix position.

The main constitution of structure

The main structure contains trolley, lifting mechanism, traveling mechanism of trolley, traveling mechanism of crane

Hook group

The overhead crane is designed and manufactured strictly in according to GB/T 10051-2010 standard. The hook of the overhead crane is forged.

On the mouth of the hook is set with fastener, which is to prevent the handled materials from falling.

The specific value of the diameter of the pulley is 20 bigger than the diameter of the steel wire rope. All of the pulleys are set with protective cover or the device to prevent the steel wire rope from jumping from the concave-groove.

Wheel parts

The bearing support of the wheel parts adopts vertical angle-type structure. By means of bolt, the vertical angle box is fixed on the angle block of the trolley frame or the end girder of the gantry. The structure can adjust the wheel when it is used to maintain. It can avoid the rail gnawing which is caused by the lateral deviation and vertical deviation. The vertical angle box is a mature technology which is used widest at present.

The choosing of the diameter of the wheels and the materials depend on the max.loading capacity of the wheel and the most unfavorable condition. It aims to avoid the overloading of the wheel parts.

The material of the wheels adopts ZG340-640 and the it must experience advanced quenching by induction heat treating. The hardness should accord with:

The hardness of tread and inner side of rim (HB) ≥300~380

The min. depth of hardening zone (mm) 20

The min.hardness of depth of hardening zone(HB) ≥260