Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:100 set/month

Production

The machine has compact structure and high production efficiency. It apples the bowl-type bearing with high precision, moreover, due to the concentrated diluted oil lubrication system and the novel dry oil sealing&dust-proof system, the safety spring device can protect the equipment when the broken materials fail to be conveyed to the crushing cavity, given this, the machine is always used for the second-level and third-level crushing. Therefore, it is suitable for breaking the ores and rocks which have medium or above hardness, such as, iron ore, cooper ore, limestone, quartz, granite, sandstone and others. Therein, the standard machine is suitable for the intermediate crushing, however, the middle-sized and short head-type machine shall be applied for the fine crushing, in summary, the machine is widely used in the mineral separation, building materials, water conservancy, chemical engineering and other fields.

Structural features

It has large crushing ratio.

The materials particle size is satisfactory.

The discharge port can be adjusted conveniently and rapidly.

It is equipped with anti-iron overload protection.

The mortar rolled wall has uniform abrasion and long service life.

It applies dry oil or water sealing mode.

The product has low repairing costs.

The product can be operated steadily with high reliability.

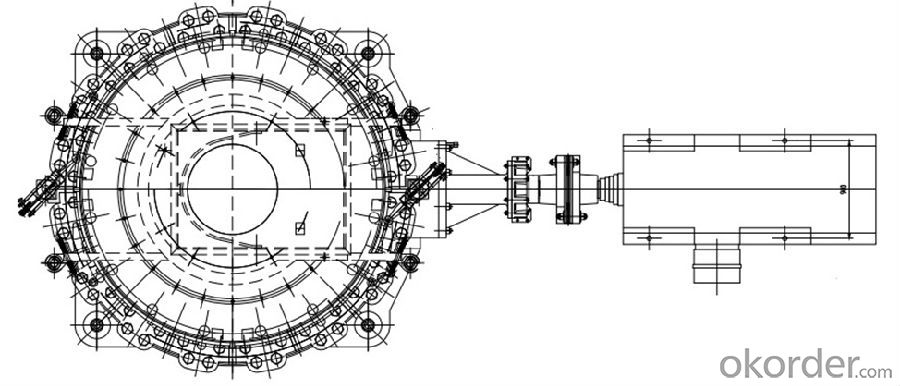

Parts of the spring cone crusher

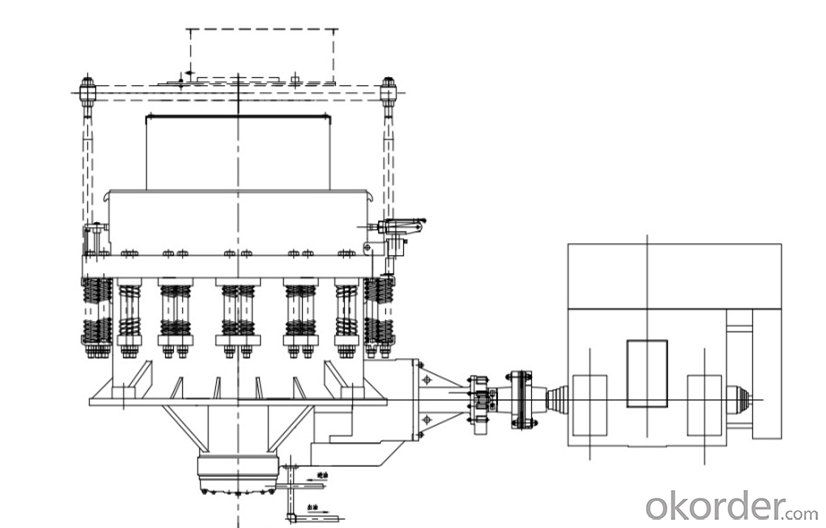

The spring cone crusher is mainly made up of rack, transmission, eccentric hollow shaft, pivot type bearing, breaking cone, adjusting device, adjusting sleeve, spring, hydraulic power unit for adjusting throat and other parts.

According to horizontal shaft and a pair of bevel gears, the electric motor drives the eccentricity axis sheath spinning when it is in operation. Under the force of eccentricity axis sheath, the shaft axis of breaking cone makes a swirl pendulum movement, which makes the crushing wall close to the wall of mortar rolled ever now and then. As a result, the material in the crushing cavity are crushed by continuous squeezing and bending.

Working principle

In the light of the hydraulic clutch, small bevel gear wheel, the electric motor drives the big bevel gear wheel on the bottom of the eccentricity axis sheath, which makes the the eccentricity axis sheath spin. It can result in the crushing of the materials caused by the rotation and swing of cone. The principal axis of the crusher is motionless that it is mainly to bear the crushing force. Owing to the principal axis of the PY spring cone crusher is motionless and the eccentricity axis sheath spin is used to deliver crushing force, thus, the eccentricity axis sheath spin will bear bigger crushing force. It quite adapts to broken bits and ultra-broken bits, because the crushing force of the broken bits and ultra-broken bits are quite big. The spring cone crusher is mainly used in the third crushing phase in metal mine ore treatment plant or the fourth phase. It adapts to the construction material or non-metal mini and civil engineering. Especially, it is used in the district where the supply of the natural sand is in the short for the civil engineering.

Performance of the mechanism

The spring cone crusher has higher off-take potential. Also, it has a great quality.

Because it is equipped with safety device, it can quite reduce the time caused by stop time.

The body of the spring cone crusher is made of cast steel structure. At the heavy load position, it adds reinforce rib.

The spring cone crusher is equipped with regulator, which can reduce the particle size of the discharging granularity.

And, it is equipped with spring-type protection device.

The spring cone crusher has a completed lubrication system. The system will stop automatically when the temperature is over high or the speed of flow is over slow

The inner structure of the spring cone crusher has a good sealing performance, which can effectively protect the spring cone crusher from damaging by the encroached dust and other small size particle.

The spring cone crusher has a long service life. Also, it has a strong adaptability.

Technical specification

Model | Max feed size(mm) | Discharge gate adjusting range (mm) | Processing ability(mm) | Power (kw) | Weight (t) |

PYD900 | 40 | 3-13 | 14-50 | 65 | 11.3 |

PYB900 | 115 | 15-50 | 49-85 | 11.2 | |

PYZ900 | 60 | 5-35 | 20-65 | 11.2 | |

PYB1200 | 145 | 20-50 | 110-168 | 110 | 24.7 |

PYD1200 | 50 | 3-15 | 17-105 | 25.3 | |

PYB1750 | 215 | 25-60 | 280-480 | 155 | 20.3 |

PYD1750 | 85 | 5-15 | 75-230 | 50.2 | |

PYD2200 | 100 | 5-15 | 120-340 | 280 | 83.5 |

PYB2200 | 300 | 30-60 | 590-1000 | 83.1 |

Notes:

The processing capacity of crusher as specified in the table is based on the transient sampling measurement result;

It is conducted for the materials which have 1.6t/m³bulk density;

The date as specified in the table are related to the process system of the supporting equipment on the site, however, which are only used for reference when users make model selection.

FAQ

Is the spring cone crusher Simons cone?

Not definitely. Our company has continuously upgraded and optimized all kinds of crusher. Also, the spring cone crusher has been upgrade and optimized many times. The performance of the spring cone crusher is higher than the Simons cone crusher.

What’s the transmission method of the spring cone crusher?

In the light of the coupling, the electric motor connects with the main engine directly for operation.

What’s the biggest specification can the company manufacture?

At present, the biggest diameter spring cone crusher manufactured by our company is 2200mm.