Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

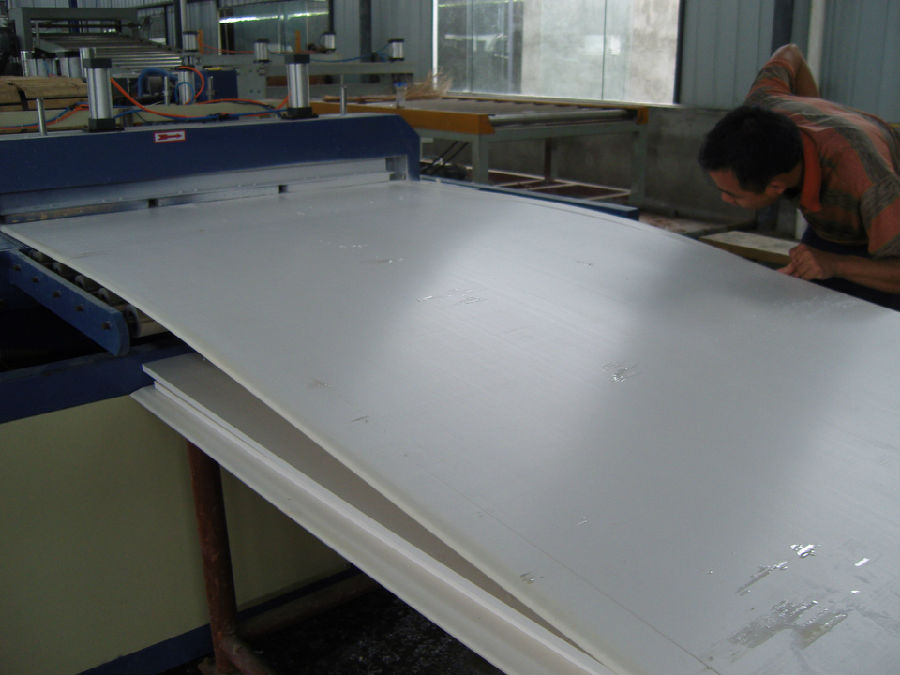

PVC skinning foam board extrusion line

Extruding product characteristics:

1). Waterproof, antiflaming, dampproof, rotproof, mothproof, light weight, keep temperature, sound and heat insulation and shockproof etc;

2). Color-way is not changed long time and not easy to aging under radiation resistance;

3). This product can be manufactured by general wood processing tools. It can be drilled, sawed, nailed and dig. It is the best substitute to raw wood, aluminum and composite product;

4). It can be welded as every general welding stipulation and also can be stick to other PVC materials.

5). It has smooth surface and is easy to print.

Technical configuration Specification of Pvc foam board Machine

| ||||

Name | Description | DETAILS | ||

1 | SJSZ 80/156 Conical twin Screw Extruder | ABB frequency converter, SIEMENS conto actor, OMRON Japan | ||

2 | Mould | hanger type extruding mould “EKO” | ||

3 | Foaming Machine | 4 phase calibrating device(hydraulic) | ||

4 | Cooling tank and bracket | Length:6000mm + Trimming knife: 3 sets | ||

5 | Haul-off unit Gear transmission | 8 couples (Cylinder clamping and loosening) | ||

6 | Automatic Cutting unit | 1set (controlled by ABB inverter) | ||

7 | Stacker machine | 1set | ||

8 | Colling Chiller 20P | 1set | ||

9 | Dust exhaust device | 2 sets | ||

Auxiliary machine | ||||

1 | 500/1000Mixer | 500L or 1000 L mixer (controlled by Inverter) | ||

2 | 500 Grinder | feeder controlled by ABB Inverter, with automatic dust collector | ||

3 | SWP 380 Crusher | rotation blades 9 pcs | ||

ATTENTION | ||||

1 | Main motor frequency controller : siemens or ABB | |||

2 | Temperature controller : OMRON or RKC | |||

3 | AC controller : Schneider or simens(As customer requirement) | |||

4 | Thermal overload relay : Schneider | |||

5 | Switch : DELIXI or Schneider | |||

6 | All electrical units on components from standard companies like OMRON/RKC/Siemens | |||

After-sales service

Technical documents

All labels on machines and lay-out drawings, Electrical diagram, User Manual, will be in English.

RUNJIA should send all necessary files to the buyer since the third week since project execution.

All documents in hard copies should be also shipped with machines together.

Arrangement for inspection, installation and testing work

a. After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

b. Engineer will give free training lessons to labors in buyer’s factory.

Quantity and quality guarantee

a. Quantity/Quality Discrepancy to destination port during transportation:

b.Guarantee period and after-sales services: 12 months since date of bill of lading

During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us.

Long-term service:

we will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.