Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:8 m.t.

Supply Capability:1000 m.t./month

Structure of Prepainted Aluminum Sheet/Coils Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Prepainted Aluminum Sheet/Coils:

1) Perfect weather ability, high strength, no special maintenance

2) Convenient construction, short working time

3)Excellent machining heat insulation, sound insulation property and perfect fireproof performance

4) High plasticity, good impact resistance, quakeproof performance and reducing buildings load

5)Goods smoothness, lightweight and rigid, beautiful and cheap

6) Various colors available

7) Simple machining equipments, processing in spot.

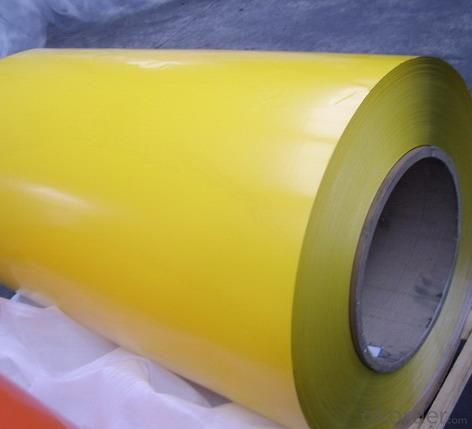

Images of Prepainted Aluminum Sheet/Coils:

Prepainted Aluminum Sheet/Coils Specification:

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

STANDARD

| EN10142 JIS G3302 GB/T-12754-2006 | ASTM A653 JIS G3302 SGCC/SGCH GB/T2518 European Standard | ASTM A792 JIS G3321 JIS G3317

|

GRADE

| CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 GRADE

| SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

Mode No of prepainted steel coil | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

Type of prepainted steel coil

| Steel coil Steel sheets/plates Corrugated steel sheets/plates

| Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates

|

Technique of prepainted steel coil | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc

|

Surface treatment of prepainted steel coil | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating

| |

Application of prepainted steel coil | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

FAQ of Prepainted Aluminum Sheet/Coils

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 1000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

Aluminum Coil: An Earth-Friendly Industrial Material

Whether a project calls for aluminum foil (thinner than 0.006 inches in thickness) or aluminum sheet (0.006 inches to 0.070 inches in thickness), aluminum coil is behind the manufacturing process. Aluminum coil is formed by taking one continuous strip of aluminum and coiling it into a roll.

Some of the advantages of aluminum coil is that it is lightweight, heavy duty and able to resist corrosion. By a process called anodizing, whereby the aluminum surface is coated with a protective oxide, that corrosion resistance can be improved even further. As a result, manufacturers who need to increase their productivity and require parts that can withstand the elements rely on aluminum coil to get the job done.

Why might they opt for aluminum coiling over another durable material like steel or copper? At about 33% the density and weight of steel, aluminum renders parts that are much lighter, thereby reducing handling costs and shipping fees. What's more, is the cost is about 50% that of copper.

In fact, according to the Air Conditioning, Heating, Refrigeration News, aluminum versus copper has become "The Great Condensing Coil Debate." In that article published by the industrial news source, while controversy stirs about one versus the other, one thing is clear. Condensing coils made from aluminum have made air conditioning more affordable. "That (aluminum coil) brought the cost of an a/c system down, making it more palatable to consumers and builders."

But the heating, ventilation and air conditioning sector isn't the only industry in which aluminum coil is used. The transportation industry, in fact, is the largest user of the product in the United States, accounting for close to 30% of all that is produced in the nation. Indeed, the average car driven in this country contains over 275 pounds of aluminum, and some luxury car makers use aluminum sheeting to make the entire bodies of their vehicles. Perhaps that's why aluminum has become the most abundantly produced non-iron metal.

In the construction industry, aluminum coil is also being used more and more frequently as trim to cover base materials on homes. Because the aluminum can be anodized with a decorative oxide and comes in a wide variety of colors, it provides a pleasing finishing feature. Best of all, it is easy to install, making it a nice home project for the do it yourselfer. The most typical way in which aluminum coil is put to use in homes is as a trim finish for windows, soffit boarding, siding and roof edging.

Beyond these industrial advantages, aluminum is extremely kind to the environment thanks to its ability to be recycled. That ecological friendliness is further enhanced by aluminum's ability to be recycled an infinite number of times. In the transportation industry alone, that adds up to substantial benefits to the earth. In concrete terms, the average car is made up for about 7% aluminum, yet aluminum amounts to around 40% of the total material scrap value of the average vehicle at the end of its useful life.