Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

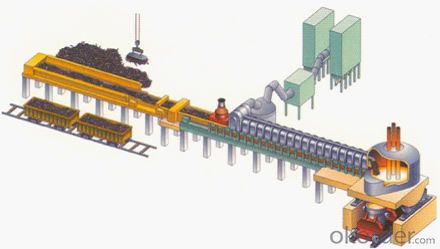

AE series preheating continuous feeding equipment is the most advanced, clean, energy saving and environmental protection metallurgy off gas using equipment in nowadays. This is using the off gas from the electric furnace to preheat the raw materials, and avoided the high failure rate, complicated operation, can not charging materials continuously and etc weakness from Shaft furnace preheating and preheating bucket and etc traditional ways. This system has been put into production in more than 20 factories in china and several other countries. And had gain marked affects in electricity saving, energy saving, production increasing, pollution reduction, and brings great economic benefits for customers.

AE series preheating continuous feeding equipment has characteristics of continuous feeding, continuous melting, continuous smelting and etc… which advantages are: short smelting period, low power consumption, low noises, low investment cost and etc…

Compared with the traditional EAF, the technical index of continuously preheating and feeding EAF process are:

1. Production capacity increases more than 10%.

2. Smelting cycle is shortened by 10-15 Min.

3. Save energy of 100-120kw.h/t for per ton Steel.

4. Electrode consumption decreases by 0.5-0.8%, Refractory material consumption reduces by 5%.

5. 20-30% reduction of CO2 volume which is released from per ton of Steel; Production site dustiness less than 10mg/M3.

6. Dioxin and CO emissions meets relative emission standards, smoke and dust is decreased from 17kg/t to 11kg/t.

7. Fully utilization of waste heat: On the Conveyor section can preheat the materials up to 300 degree Celsius and higher, and add burner in conveyor section, can raise the materials up to 600 degree Celsius. The rear part of the waste heat can be used to generate electricity or heating by steam which is produced by waste heat boiler, the gas from the boiler basically can go into the bag type dust collector directly. But the traditional electric furnace system off gas must go through the water cooled pipes, air forced cooler and etc equipments, it will consumable much energy to cool the temperature down and then can put the gas go into dust collector, so waste the energy from the off gas.

8. De-duster Fan power reduces 30%.

9. Noise is less than 90 decibels during the electric furnace smelting cycle.

With fully considering for customers kinds of actual using status, AE series preheating continuous feeding equipment brings direct economic benefits to customers by lowest failure rate, highest energy saving index, biggest investment return.

Main Technical Specifications

| Specification of | Dimensions of | Processing | Electric furnace |

(width*length) | (width*depth*length) | (t/h) | (t) | |

AE20S | 1260*65000 | 300*300*500 | 120 | 15-20 |

AE40S | 1400*46300 | 400*400*700 | 150 | 30-40 |

AE60S | 1840*48800 | 450*450*1000 | 200 | 50-60 |

AE70S | 2060*60000 | 500*500*1100 | 250 | 70 |

AE90S | 2140*60000 | 500*500*1100 | 300 | 80-90 |

AE150S | 2260*65000 | 500*500*1200 | 350 | 100-150 |