Loading Port:Tianjin

Payment Terms:L/C,T/T

Min Order Qty:3000 m

Supply Capability:300000 m/month

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

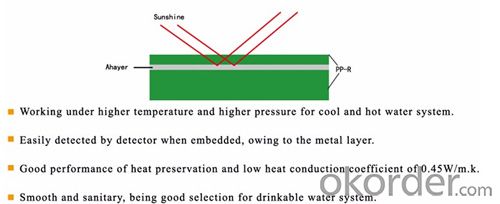

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

PPR (polypropylene random), also known as random copolymer polypropylene (PPR) having good toughness, high strength, excellent processing performance, higher temperature good creep resistance, and random copolymer polypropylene unique high transparency. It is widely used in the production of pipe, sheet, daily necessities, packaging materials, household electric appliance parts and various films.

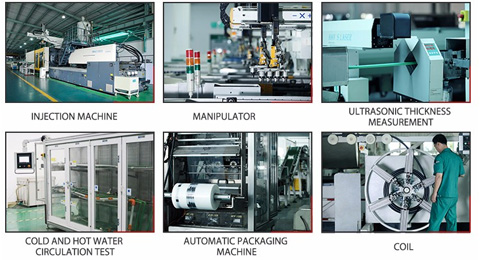

PP-R pipes called three polypropylene pipes, random copolymer polypropylene. PPR pipes by using polypropylene random copolymer can be extruded into a pipe, but also can be injection molded into the tube. A polypropylene is a random copolymer of polypropylene, its basic structure of the polymer chain to be modified by the addition of different types of monomer molecules. Ethylene is the most commonly used monomers, which cause changes in the physical properties of the polypropylene. Compared with pp Homopolymers, random copolymer improved optical performance (increased transparency and reduced haze), improved impact resistance, increased flexibility, reduced melting temperature, thus reducing the thermal fusion temperature ; while the same terms in chemical stability, water vapor barrier properties and organoleptic properties (low odor and taste) and homopolymer substantially. PPR pipes used in extrusion, blow molding, injection molding, film and sheet extrusion processing areas, for food packaging materials, pharmaceutical packaging materials and daily consumer goods.

Polypropylene pipes into homopolymer polypropylene (PP-H), block copolymer polypropylene (PP-B), and a random polypropylene (PP-R) 3 species. PP-H, PP-B, PP-R pipe stiffness decreased in order, and in turn to increase the impact strength. Water pipes are made of polypropylene extraordinary PP-R.

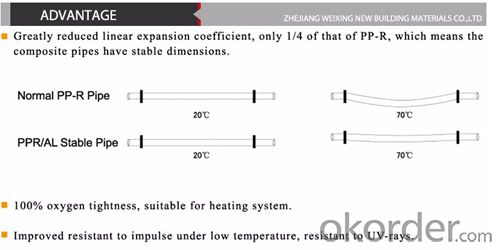

PP-R Aluminum steady plastic pipes

Aluminum steady plastic pipes product set of metal pipes and plastic pipes advantages in one, suitable for conveying medium temperature high, equipped with oxygen barrier and out the special requirements of working conditions are widely used, especially for surface mounted do radiator heating system pipes.

Decoration PP-R hot and cold water pipes

Home improvement PPR pipes system meets the demand for water under normal conditions of use. With easy PPR installation, pp-r pipes can be widely used in various types of home water supply pipeline system.

Random copolymer polypropylene products uniform implementation of enterprise standards generally: Q / 3201 GPRO 217-2006 "intermittent liquid bulk polypropylene copolymer resin special material" standard. Hot and cold water in which the products are generally executed: petrochemical industry standard SH / T1750-2005 "hot and cold water piping system with polypropylene random copolymer (PPR) Compound" standard. Hot and cold water piping system with polypropylene Executive Standard is GB / T 18742.1-2002.

A decade ago, there are new regulations for chemical building materials in China: promote the plastic pipe, out of cast iron pipe. Those pp-r pipes and fittings that not in accordance with the relevant standards of the poor quality plastic pipe modifiers, additives, additives contain many synthetic chemicals, including PCBs, including on human reproductive and developmental great harm. Environmental hormones refers to the hard plastic plasticizer - containing biphenol A, according to experts, the male sperm is reduced by half in 50 years, and women's diseases and biphenol A closely related, is the definition of foreign experts environmental hormones.

Main use:

1. Building hot and cold water systems, including central heating system;

2. Within the building heating system, including floor, wall and radiant heating system;

3. Drinkable pure water supply system;

4, Central (central) air conditioning system;

5. Use in Industrial piping systems for transferring or discharging of chemical media or other.